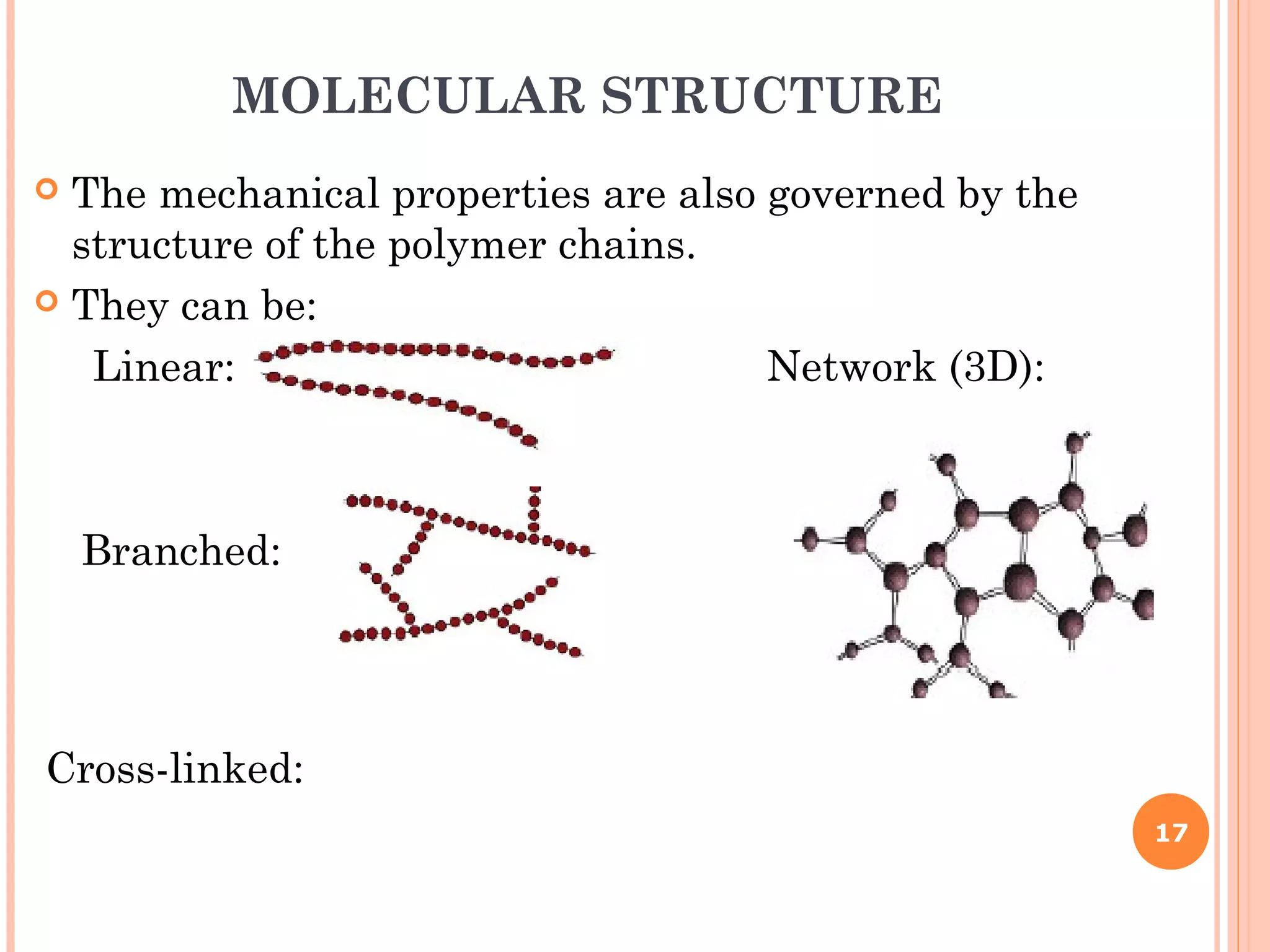

This document provides an overview of polymer science, detailing the introduction, classifications, polymerization methods, and applications of polymers in various fields including medicine, agriculture, and industry. It also discusses biodegradable polymers and their implications in pharmacy, highlighting natural polymers such as proteins and polysaccharides. The references section cites various sources related to the topics covered in the document.