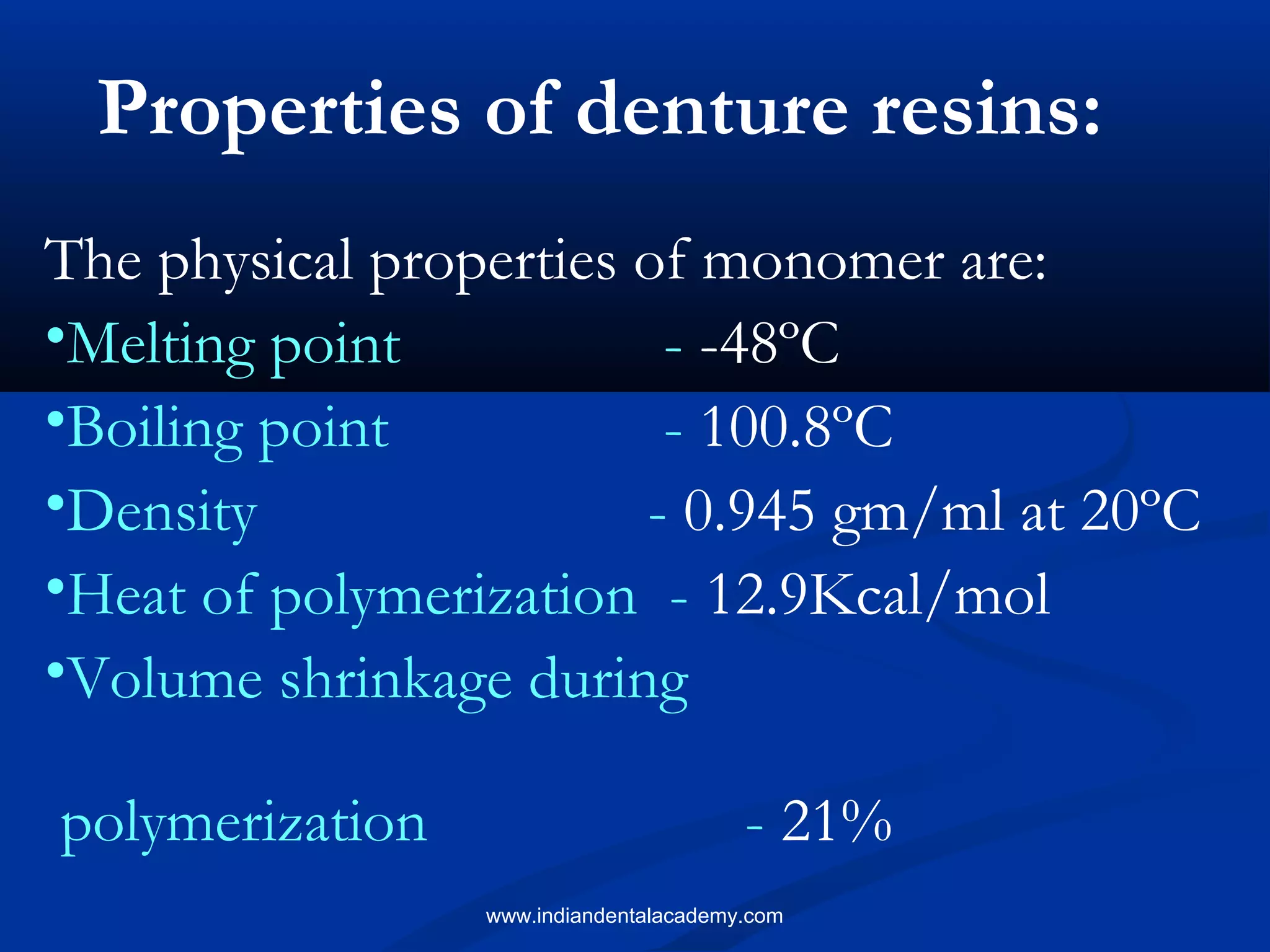

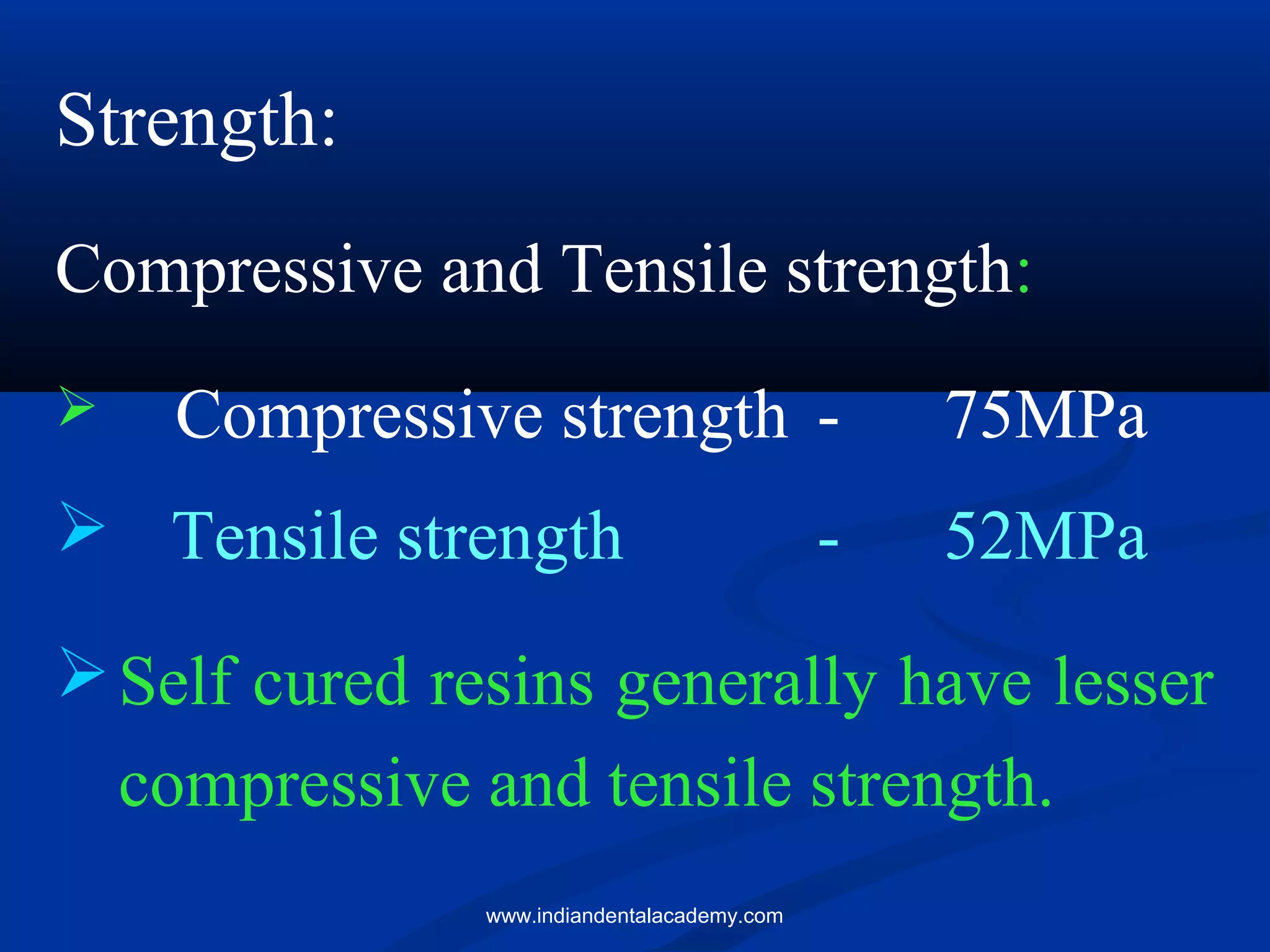

Methyl methacrylate is a clear, volatile liquid used in denture resins, exhibiting properties such as low strength and significant volume shrinkage during polymerization. Poly (methyl methacrylate) resins are tasteless, odorless, and biocompatible, with factors affecting their strength and stability including composition, processing techniques, and hydration. Additionally, issues like porosity and crazing can arise during fabrication, impacting the durability and aesthetics of denture bases.