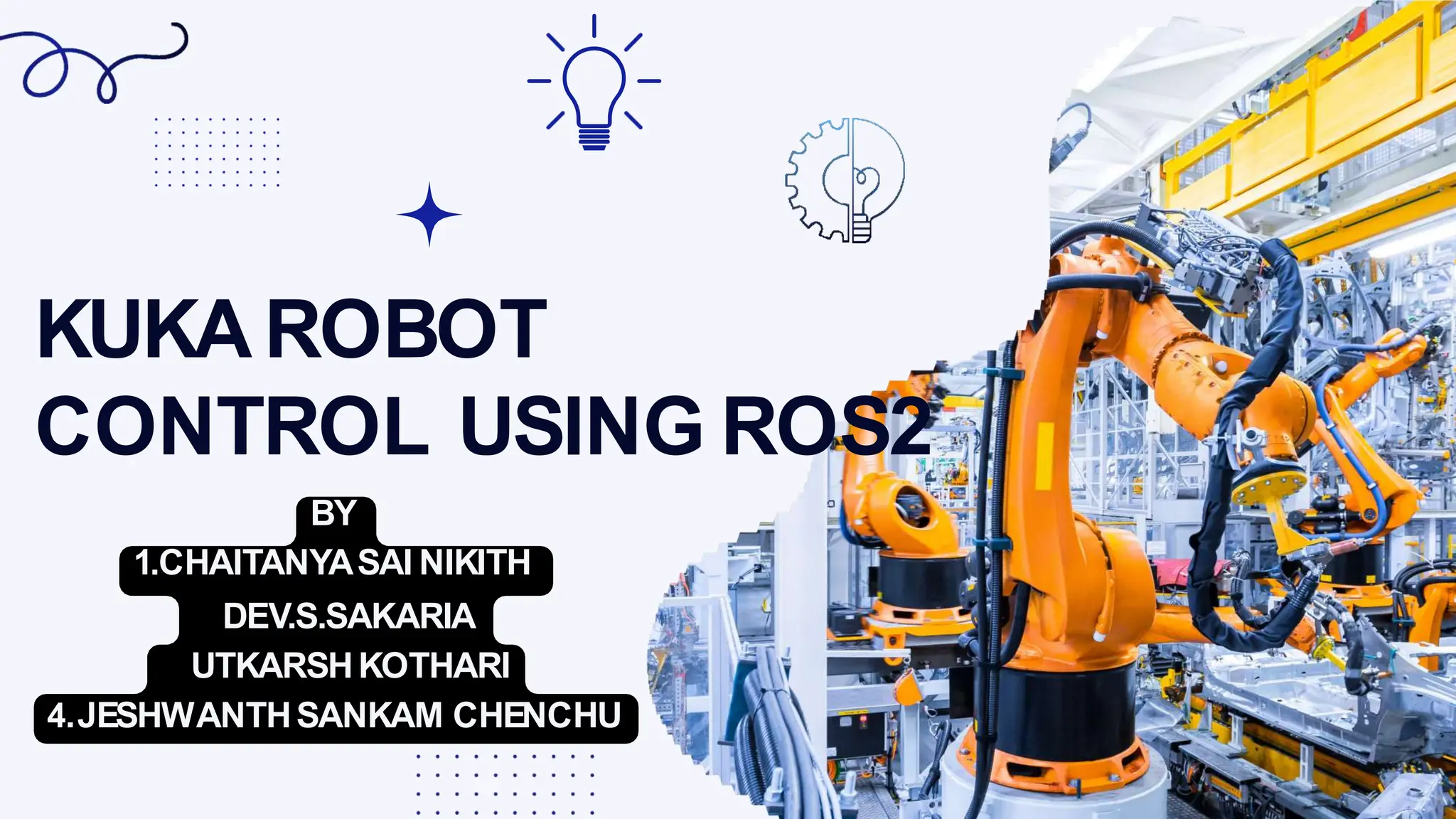

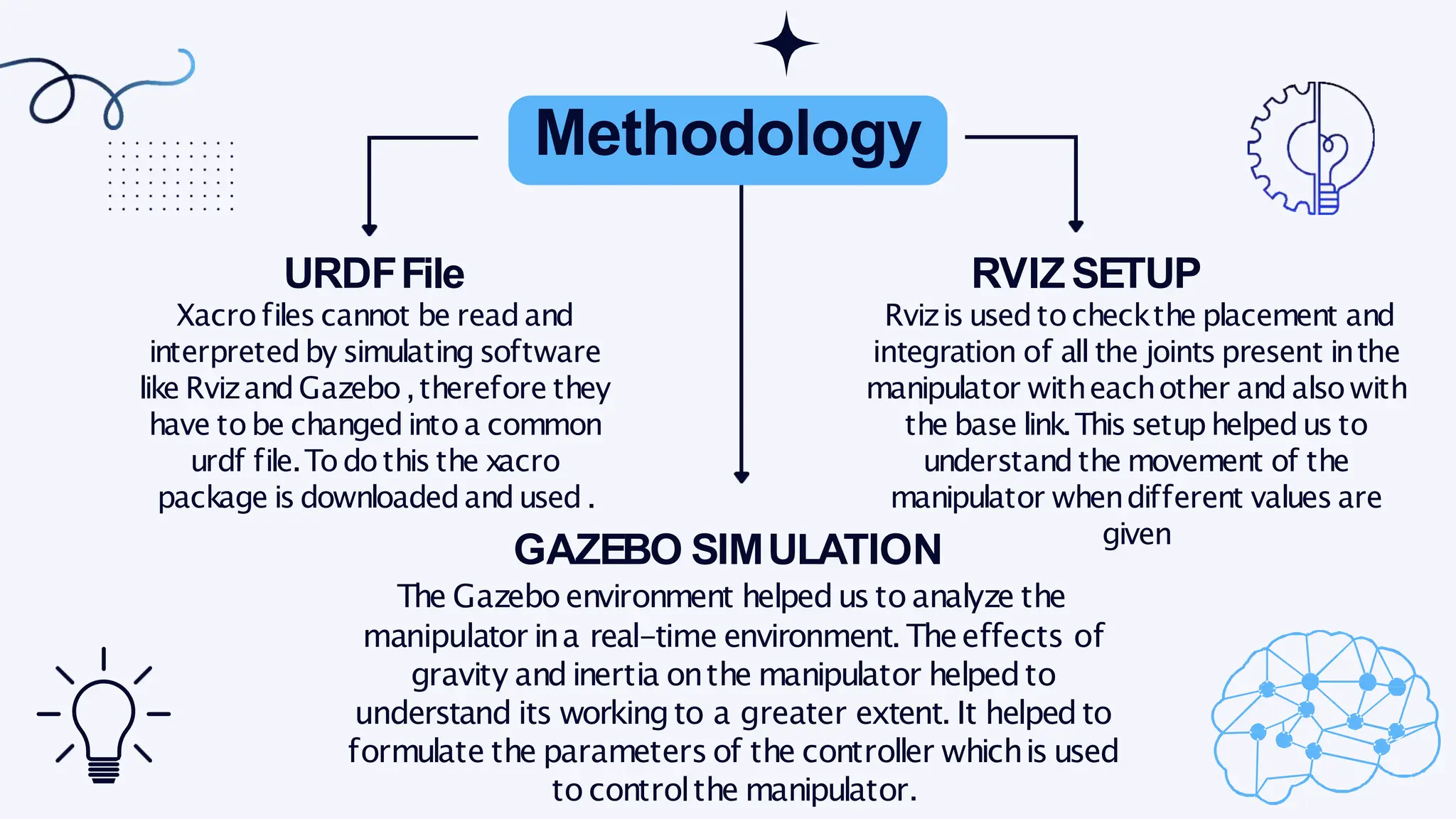

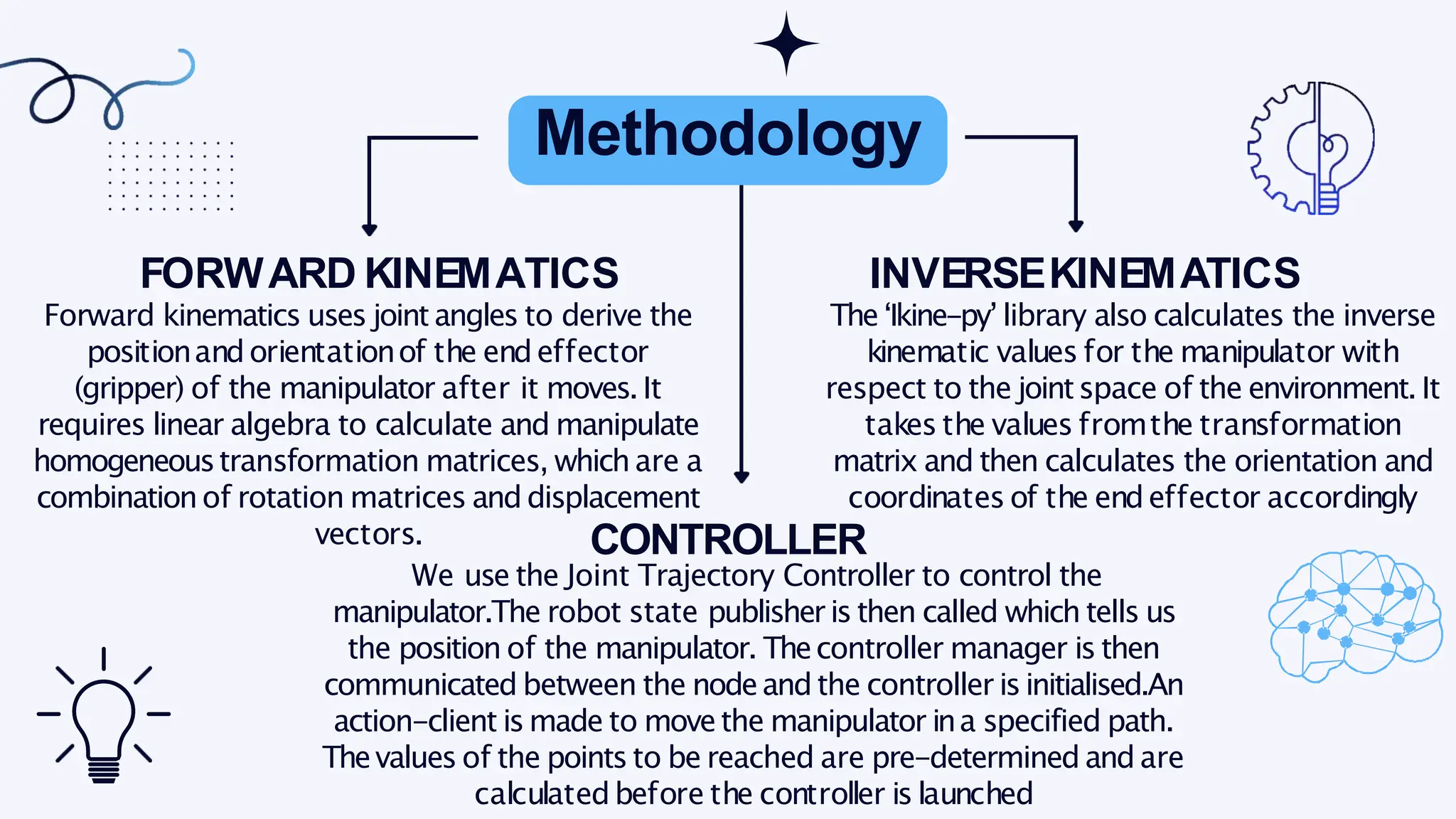

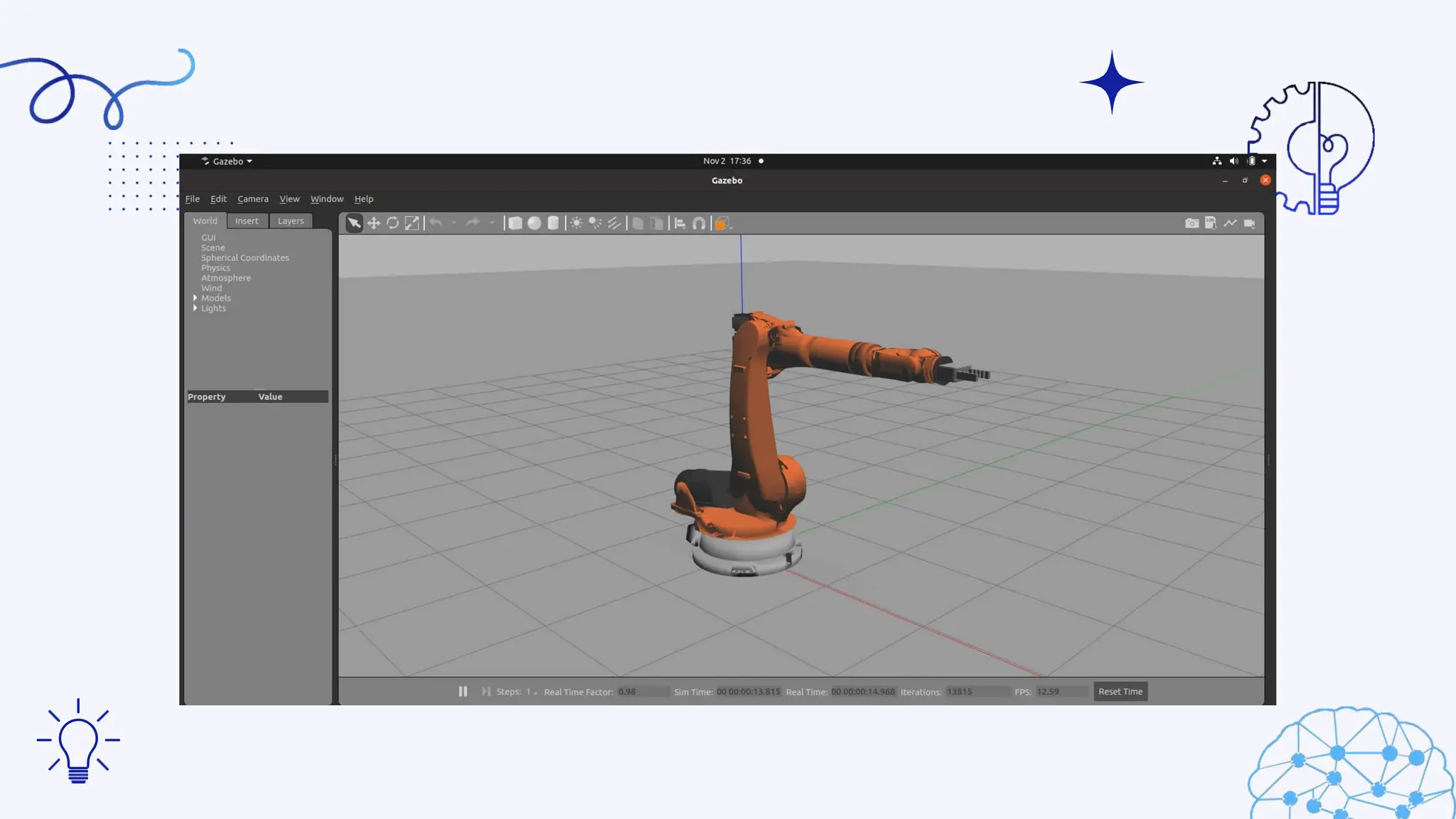

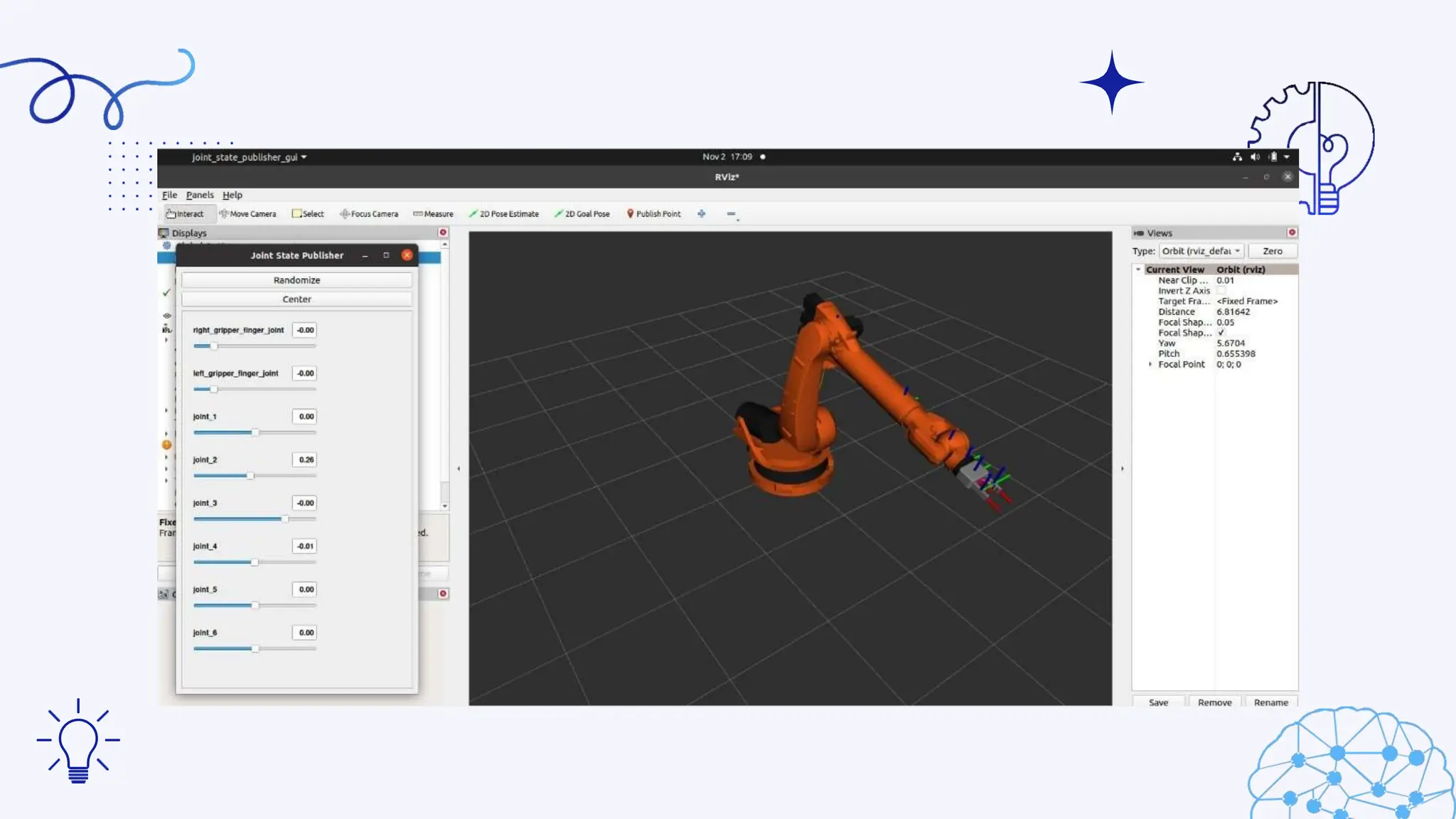

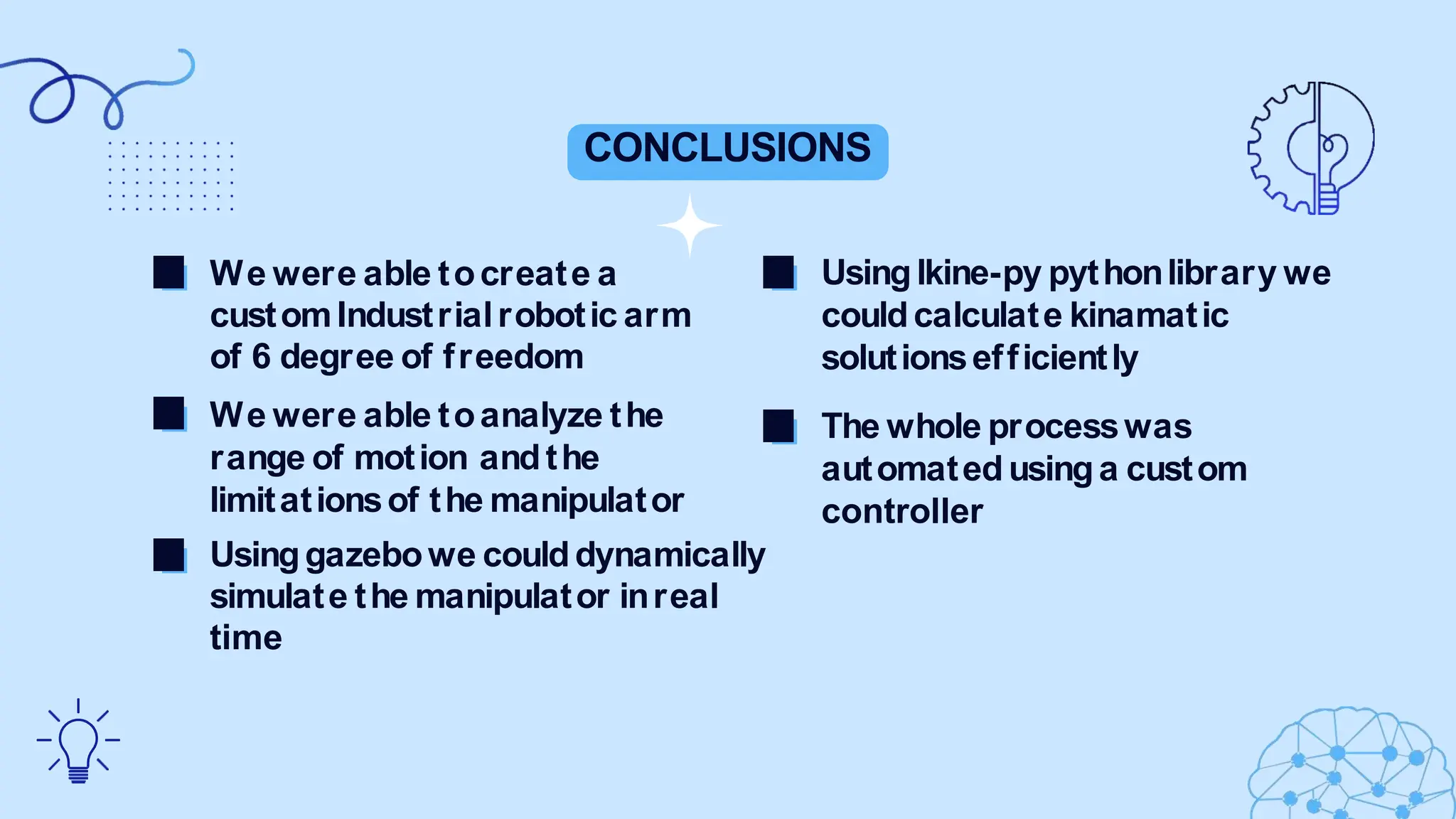

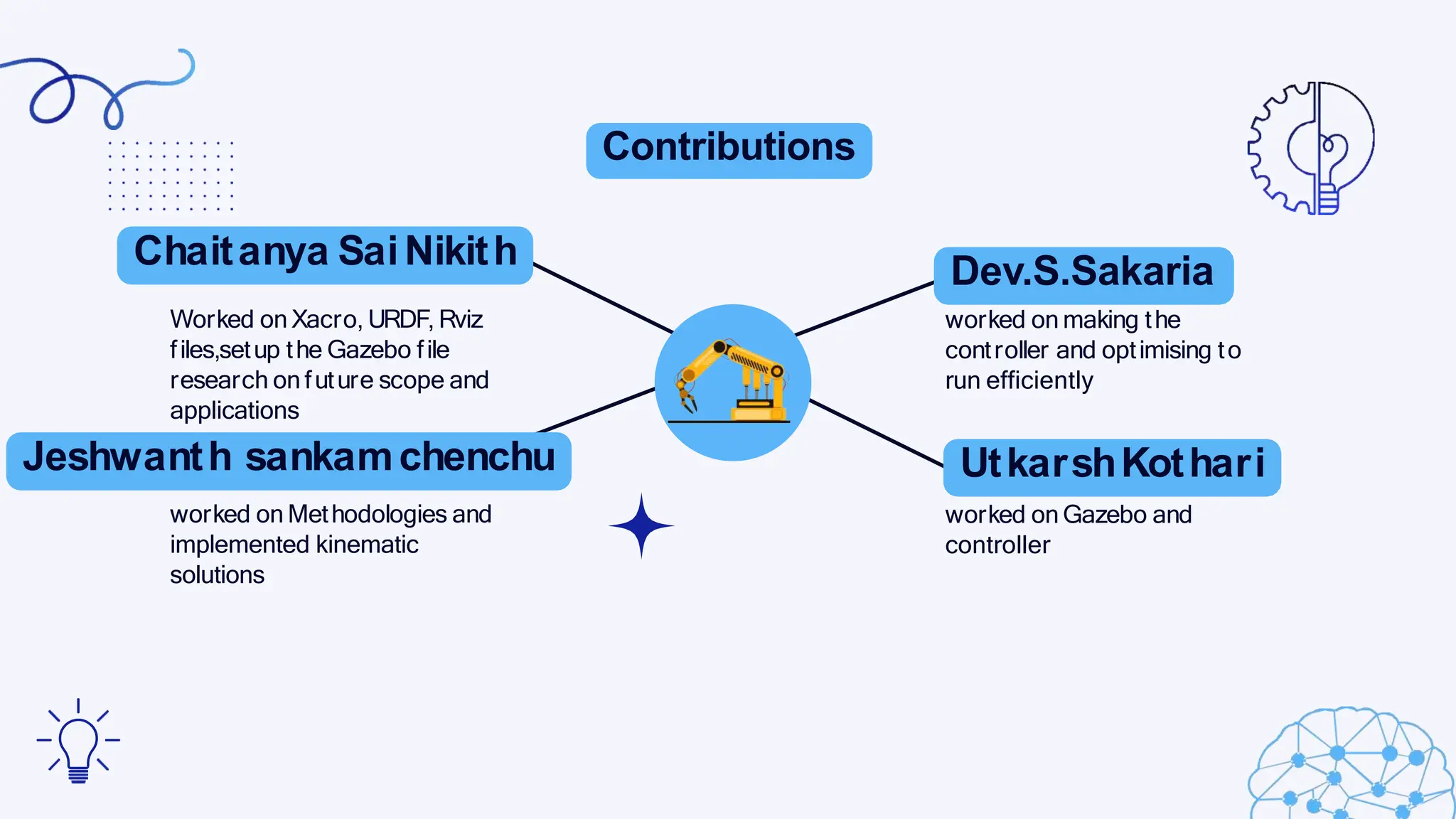

The document discusses the control of a KUKA robotic arm using ROS2, focusing on its simulation, motion analysis, and control methodologies. It highlights the implementation of kinematic equations, joint trajectory control, and the use of Gazebo for simulation, achieving a 6 degree of freedom robotic arm with specific reach and coordinate capabilities. Contributions from various authors include the development of controller and simulation files, alongside research on safety in human-robot collaboration.

![References

[1] Ore, F.,Vemula, B.,Hanson,L.,Wiktorsson, M., & Fagerström, B.(2019). Simulation

methodology for performance and safety evaluation of human–industrial robot collaboration

workstation design. International Journal of Intelligent Robotics and Applications, 3(3), 269-282.

[2] Koivo, A.J., Fundamentals for Control of Robotic Manipulators, pp. 306-338, John

Wiley & Sons, Inc., New York NY, 1989.

[3] Asada, H.and Slotine, J.E.,Robot Analysis and Control, pp. 133-183, John Wiley &

Sons, Inc., New York, 1986.

[4] Association, R.I.2012. "Ansi/Ria R15.06: 2012 Safety Requirements for Industrial Robots and

Robot Systems". Ann Arbor: Robotic Industries Association.

[5] Vemula, B.,Ramteen, M., Spampinato, G.,& Fagerström, B.(2017,October). Human-robot impact

model: for safety assessment of collaborative robot design. In 2017 IEEEInternational Symposium on

Robotics and Intelligent Sensors (IRIS)(pp. 236-242). IEEE.](https://image.slidesharecdn.com/kukarobotcontrolusingros2-240428100713-eb3eb6a5/75/kuka-industrial-robot-control-using-ros2-pptx-12-2048.jpg)