This document summarizes new developments in simulating the manufacturing process of composite structures in LS-DYNA. It discusses modeling approaches for both thermoplastic and thermoset composite materials. For thermoplastic composites, it describes modeling the temperature-dependent behavior of the thermoplastic matrix and anisotropic fiber reinforcement. It presents simulations of a picture frame test and stamping process that demonstrate the capabilities. For thermoset composites, it provides an overview of resin transfer molding and discusses modeling the 3D resin flow through fiber reinforcements during infiltration.

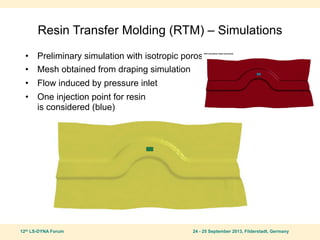

![12th LS-DYNA Forum 24 - 25 September 2013, Filderstadt, Germany

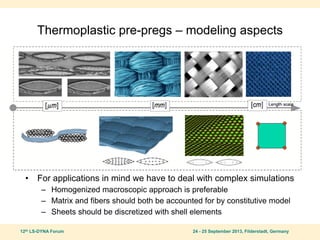

Thermoplastic pre-pregs – material formulation

• Additive split for matrix and fiber contributions

• Matrix formulation

– Elastic properties are defined with

load curves w.r.t. to temperature

– Van-Mises yield criterion is implemented

– Yield stress is given by load tables w.r.t.

• Temperature

• Equivalent plastic strain

– Return-mapping algorithm

[source: Neto et al, 2008]

[source: www.wikipedia.de]](https://image.slidesharecdn.com/kloeppeldynamore-230302194332-6a0739aa/85/Kloeppel_DYNAmore-pdf-9-320.jpg)

![12th LS-DYNA Forum 24 - 25 September 2013, Filderstadt, Germany

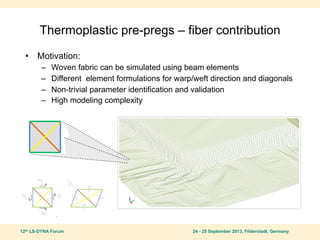

Thermoplastic pre-pregs – Work in Progress

• Presented results generated with user defined material in LS-DYNA

• Implementation as standard material *MAT_249 with

– Extension for rovings and strain-rate dependency for matrix formulation

– Elasto-plastic formulation for shear and bending of the fibers

• Improved post-processing capabilities in LS-PrePost

• Tools to map results onto the mesh for crashworthiness simulations

[source: Döbrich et al, 2012]](https://image.slidesharecdn.com/kloeppeldynamore-230302194332-6a0739aa/85/Kloeppel_DYNAmore-pdf-21-320.jpg)

![12th LS-DYNA Forum 24 - 25 September 2013, Filderstadt, Germany

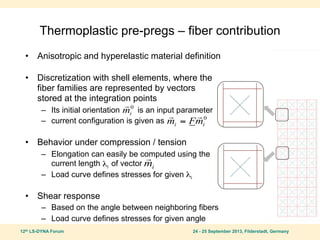

Resin Transfer Molding (RTM) –

process overview

• In general, thermosets (e.g. epoxy) have superior mechanical

properties as compared to thermoplastics

• All manufacturing processes involve a chemical curing of a liquid

resin

– Curing is induced by high temperatures and chemical additives

– Chemical reactions of curing are nonreversible

• Process overview

preparation of textile draping infiltration curing final part

[source: Benteler-SGL]](https://image.slidesharecdn.com/kloeppeldynamore-230302194332-6a0739aa/85/Kloeppel_DYNAmore-pdf-23-320.jpg)

![12th LS-DYNA Forum 24 - 25 September 2013, Filderstadt, Germany

Wet molding – process overview

• Draping and injection are done in one single step

• Process overview

• Basically, a simulation requires the same numerical tools as RTM

• Simulation more complex

– Fluid-structure interaction plays an important role

– Fluid domain, viscosity, and porosity change during the simulation

preparation of textile impregnating forming curing final part

[source: Benteler-SGL]](https://image.slidesharecdn.com/kloeppeldynamore-230302194332-6a0739aa/85/Kloeppel_DYNAmore-pdf-30-320.jpg)