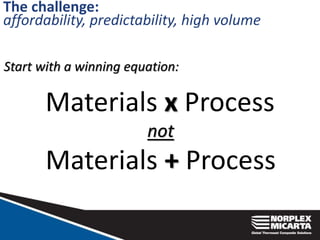

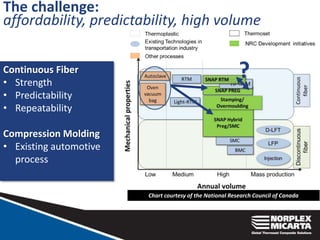

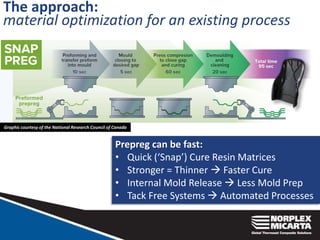

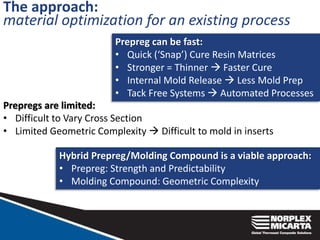

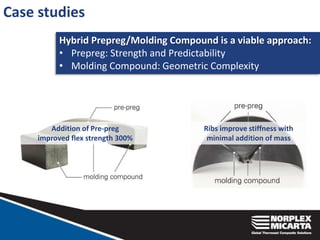

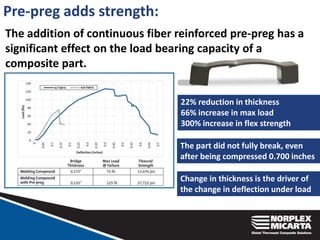

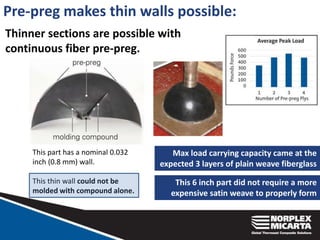

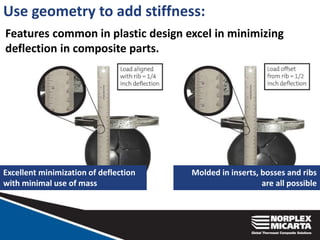

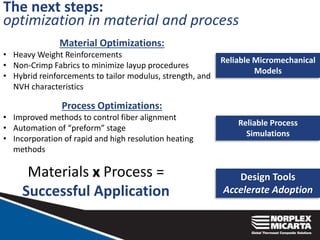

The document discusses advancements in thermoset continuous fiber pre-pregs aimed at high-volume manufacturing, highlighting the challenges of affordability and predictability. It presents a hybrid approach combining pre-preg and molding compounds to enhance strength, geometric complexity, and manufacturability, showcasing significant improvements in load-bearing capacities. Future steps include optimizing materials and processes to further address challenges associated with automotive composite applications.