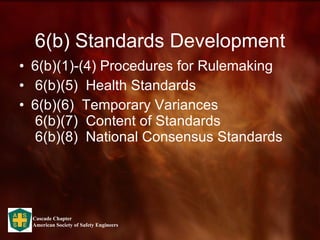

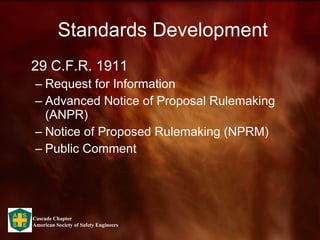

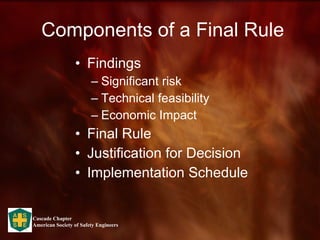

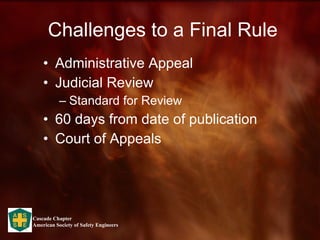

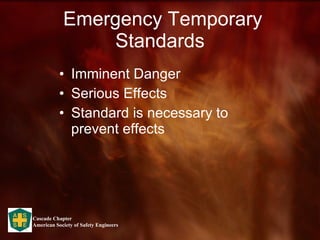

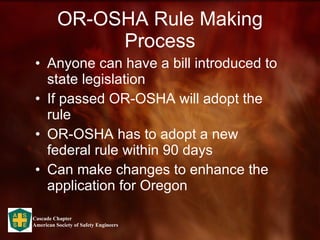

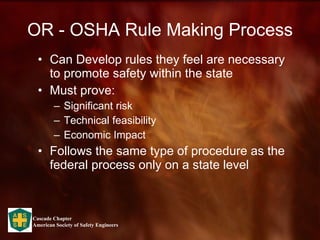

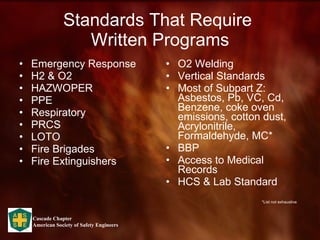

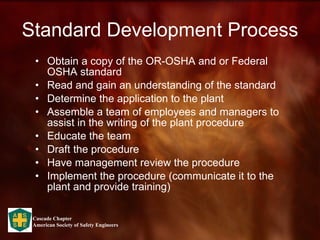

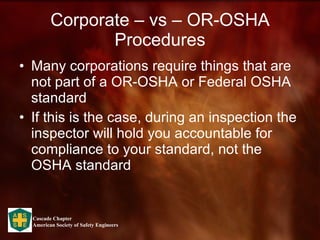

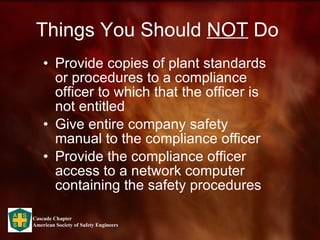

This document discusses developing effective safety standards and procedures. It covers reviewing various safety programs and principles, developing rules and procedures to guide the safety process, and the importance of management commitment to safety. It also summarizes a presentation on the federal and state rulemaking process for safety standards and tips for developing plant-specific standards and procedures.