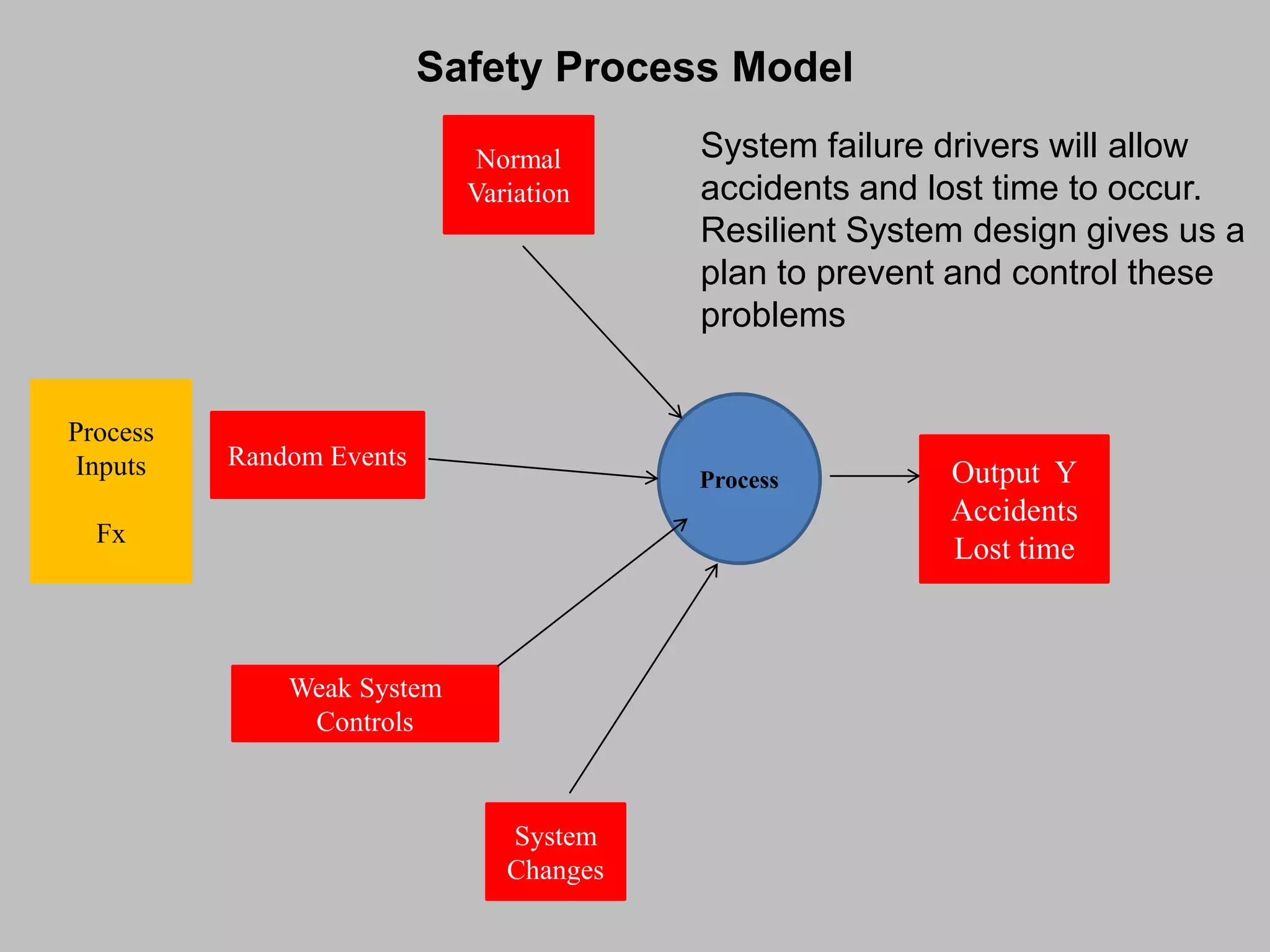

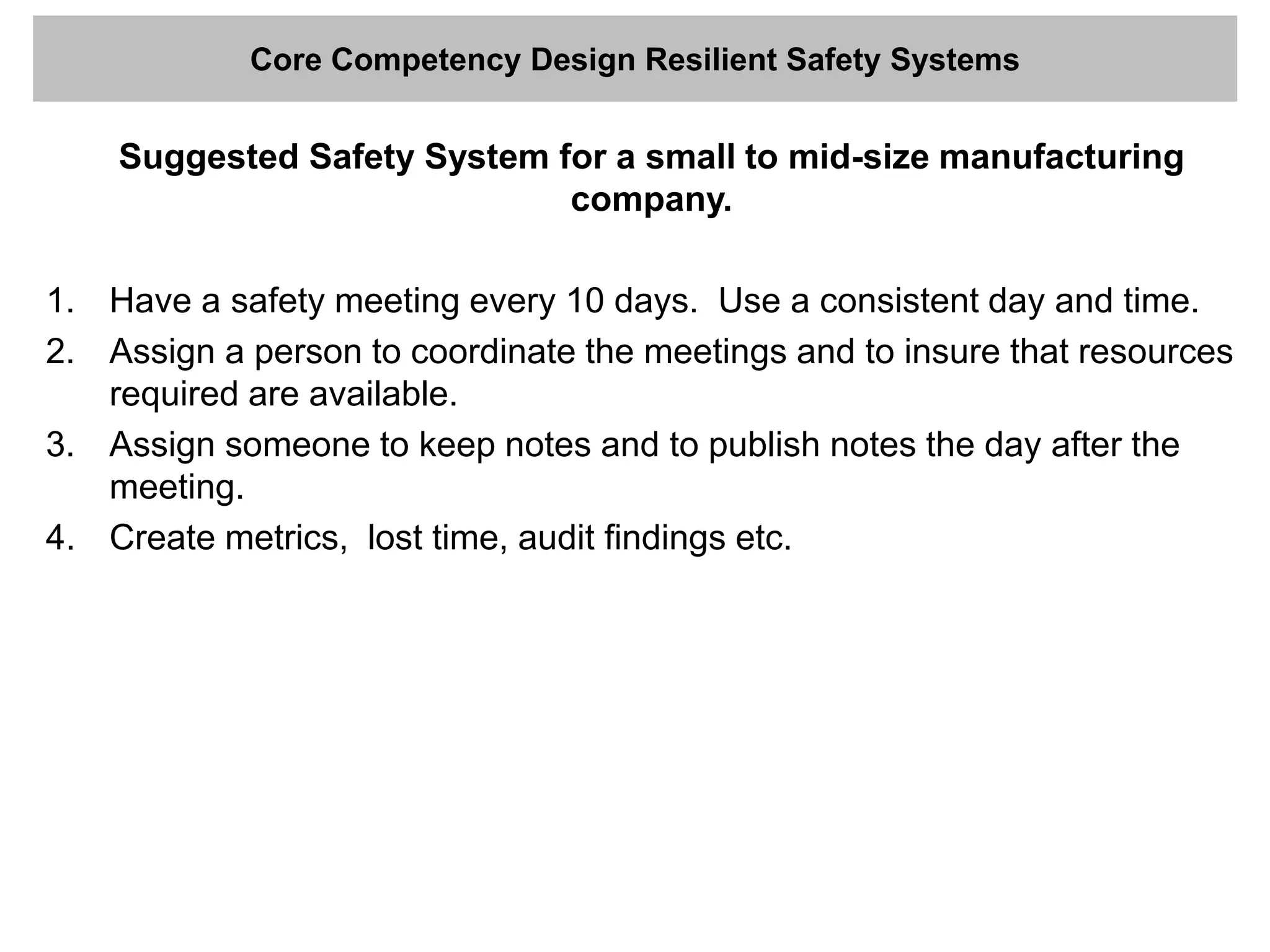

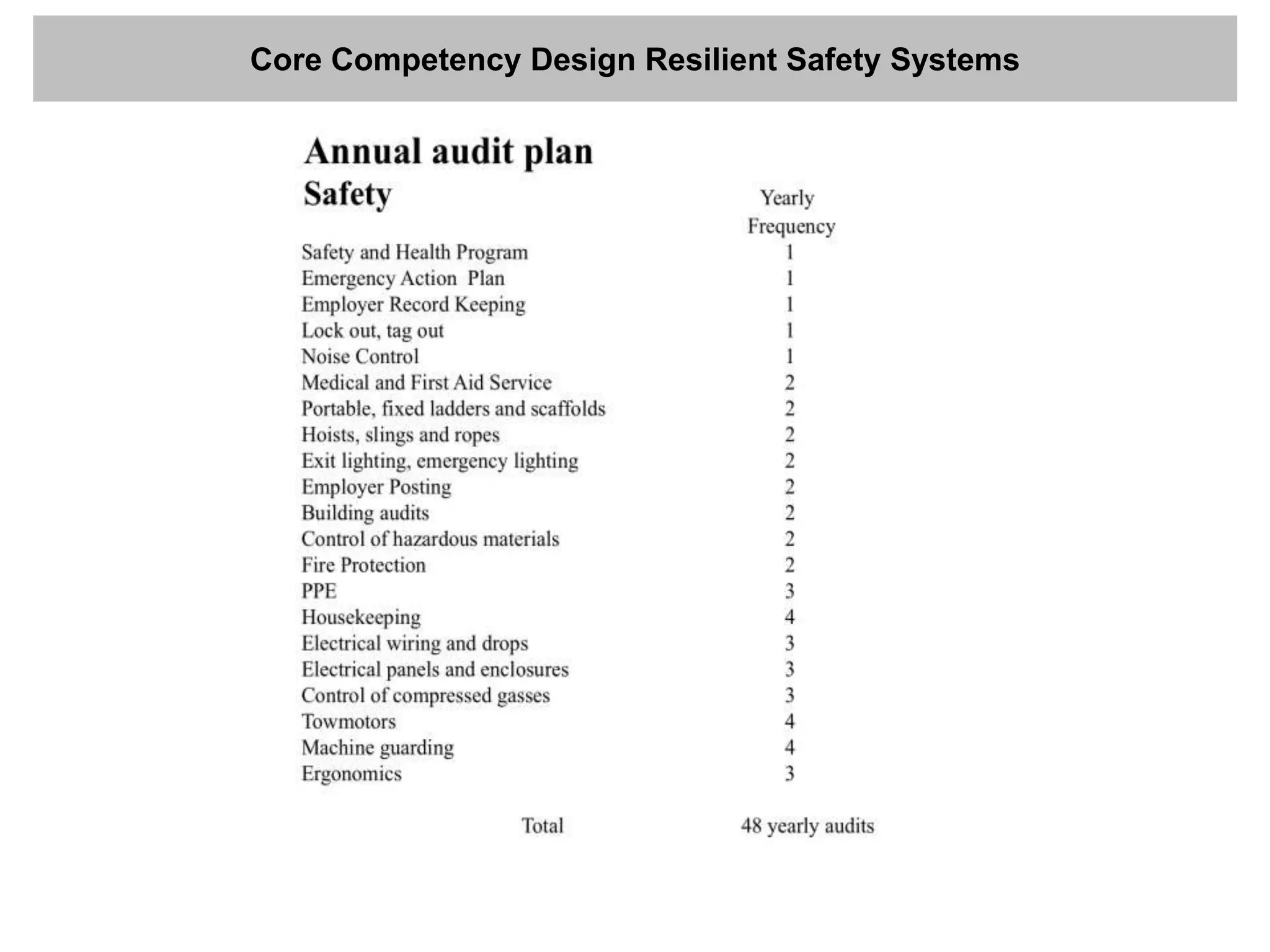

Design resilient safety systems to prevent accidents and lost time. Process inputs like materials, energy, and procedures should have controls to stabilize output and minimize risks. Simulate failures through drills to improve response and focus on ongoing prevention. For small manufacturers, suggested safety systems include regular safety meetings every 10 days to review injuries, audits, data and assign corrective actions. Create an audit schedule targeting known problems and prepare reports to share progress.