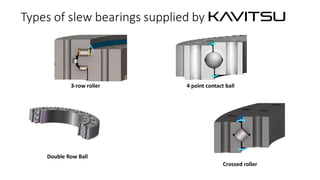

Kavitsu is an Indian engineering company founded in 1992 that manufactures slew ring bearings, gearboxes, and other industrial products. It has 4 manufacturing facilities, 300+ employees, and $550 million in annual revenue. The company aims to be globally competitive through self-reliance in design, manufacturing, and maintenance while managing its business on commercial lines. It focuses on customer satisfaction, quality, cost-effectiveness, innovation, teamwork, respect, and integrity. Kavitsu's product range includes speed reducers, gearboxes, winches, and special multi-speed gearboxes. It has in-house manufacturing capabilities like CNC, induction hardening, and a testing facility. The company serves sectors like