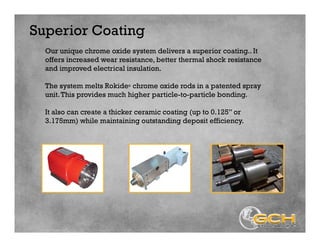

GCH Tool provides specialized spindle repair and remanufacturing services for various industries, including automotive and medical, backed by over 30 years of experience. Their comprehensive process includes failure analysis, chemical cleaning, and precision machining, ensuring each spindle meets or exceeds OEM specifications. Clients can contact GCH Tool for expert advice on spindle solutions and access to a range of new and remanufactured spindles.