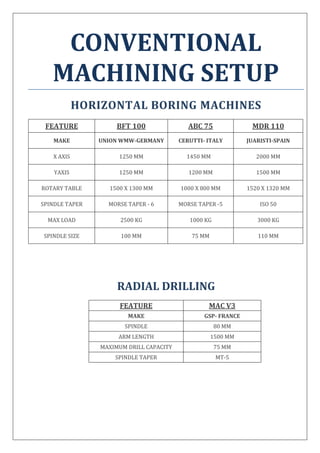

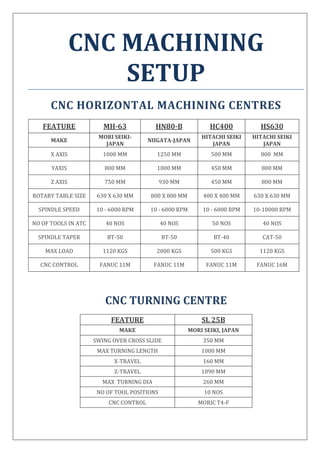

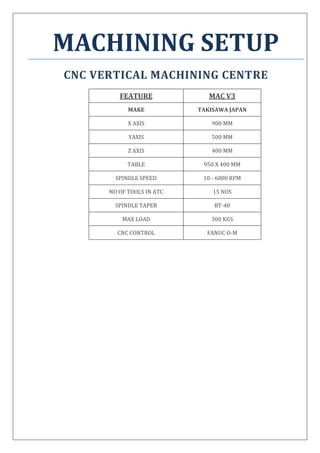

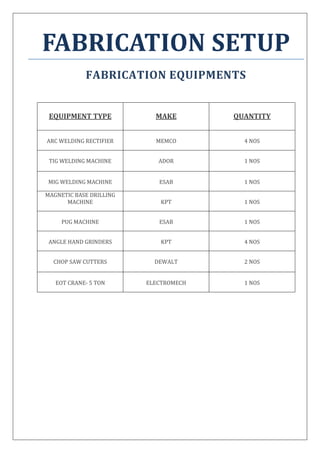

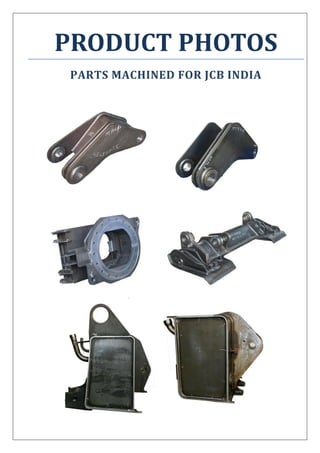

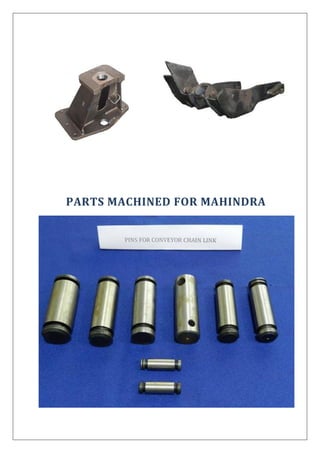

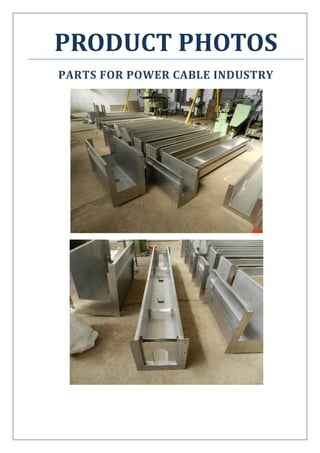

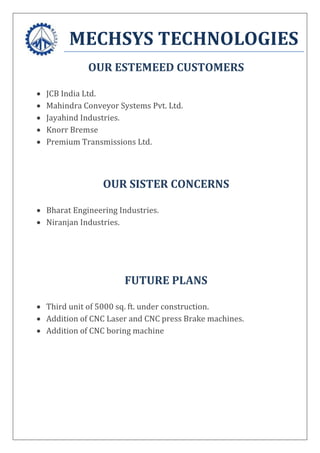

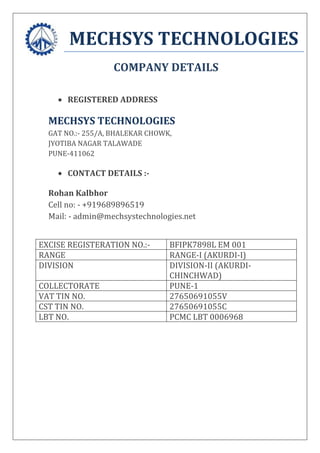

MechSys Technologies provides fabrication and machining services in Pune, India. It was founded in 1993 and offers services like heavy fabricated parts, precision machined components, sheet metal fabrication, and machining of components for earthmoving, construction, and material handling equipment. The company has a range of conventional and CNC machinery and serves customers in industries like construction, power cables, and automotive.