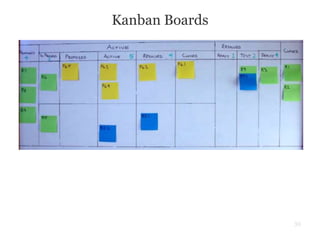

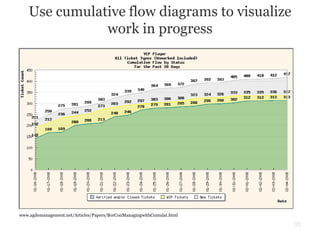

The document discusses Kanban, a lean manufacturing system used to limit work in progress. It begins by providing background on the competitive business environment and need for companies to be responsive, flexible, and profitable. It then explains how Toyota originally used Kanban cards to limit inventory and align production with demand. The document defines key Kanban terms and concepts like withdrawal Kanban, production Kanban, work in process, pull systems, and takt time. It also contrasts Kanban with traditional MRP systems. Overall, the summary discusses how Kanban aims to optimize workflow and align production to customer demand through visual signals and limits on work in progress.