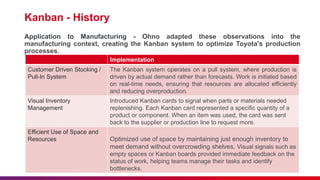

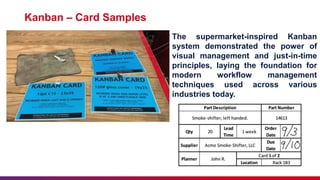

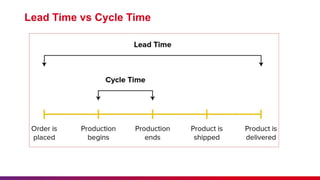

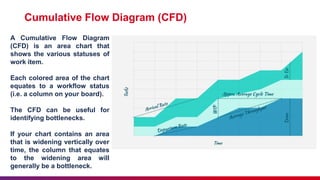

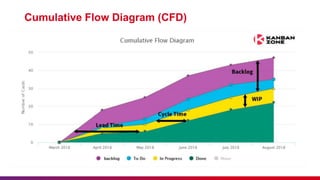

The document discusses kanban metrics and principles, emphasizing the importance of etiquette in sessions, including punctuality and giving feedback. It details the history of kanban, particularly its origins in post-World War II Japan, and how it evolved from practices used in supermarkets to optimize manufacturing at Toyota. Key metrics for kanban in software development are also outlined, including lead time, cycle time, work in progress, and throughput, alongside the use of cumulative flow diagrams for workflow management.