Embed presentation

Download as PDF, PPTX

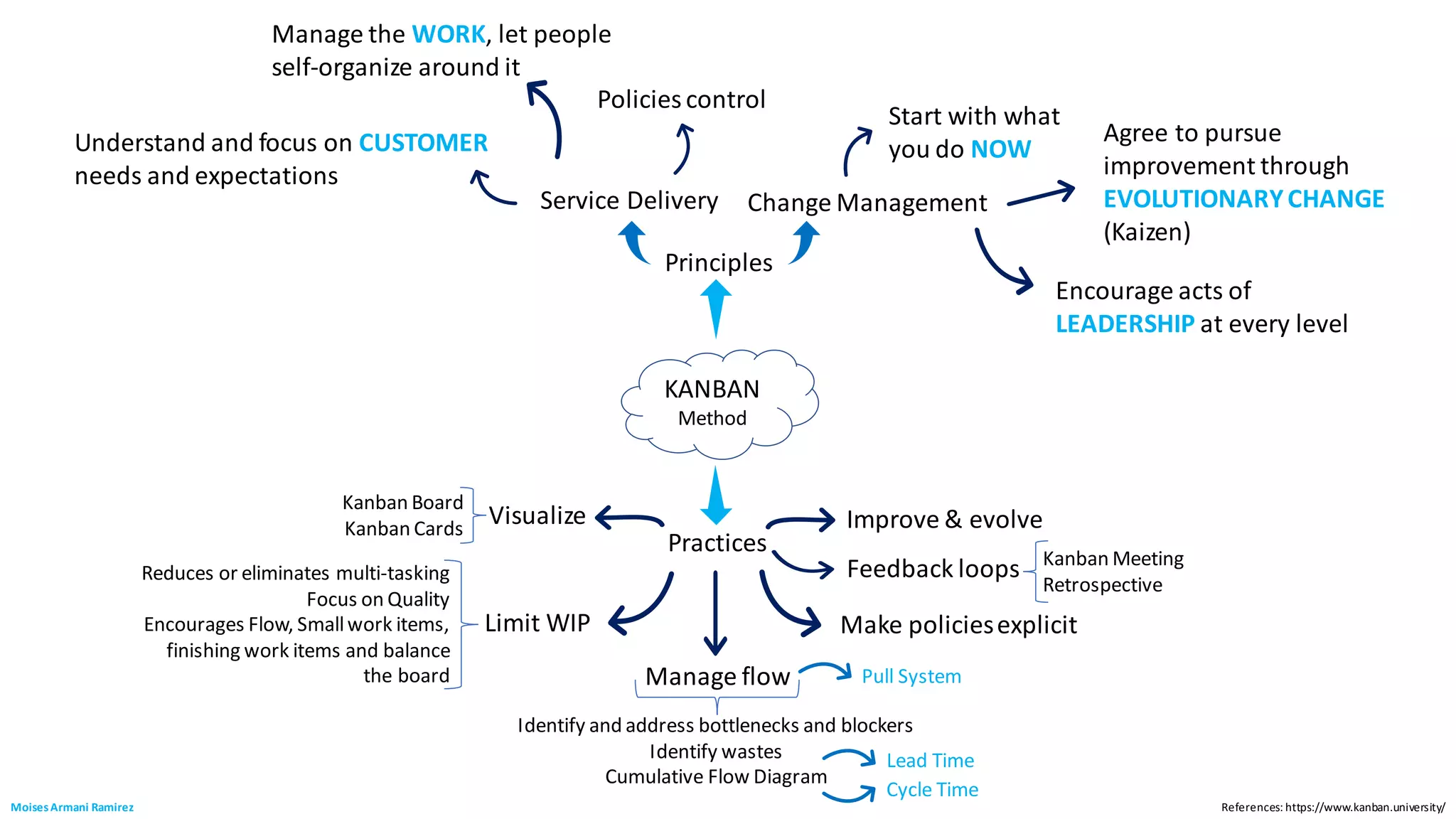

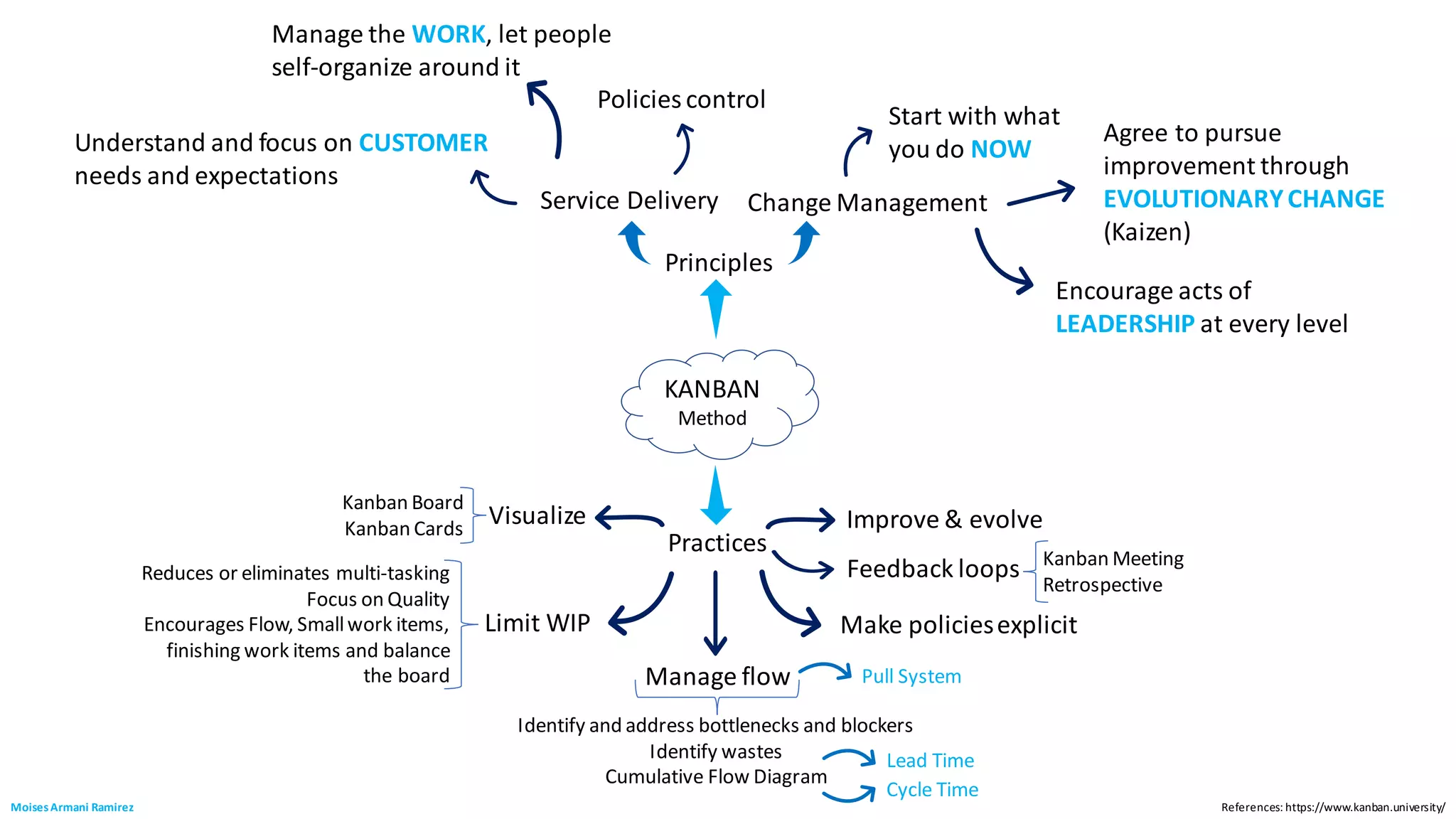

The document outlines the principles and practices of the Kanban method for service delivery and change management, emphasizing self-organization, customer focus, and continuous improvement. Key practices include visualizing work, managing flow, and limiting work in progress to enhance quality and efficiency. It also references foundational rules from Toyota's production system to ensure effective application of Kanban principles.