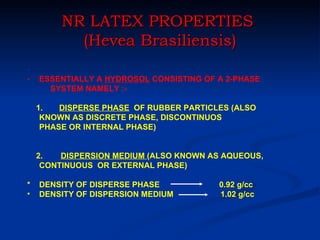

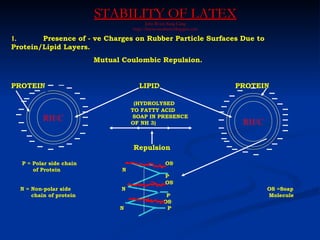

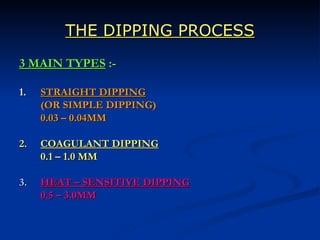

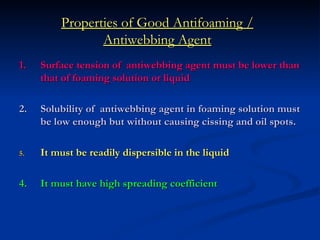

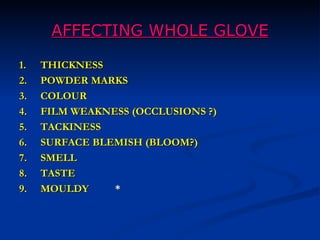

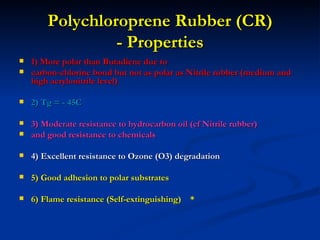

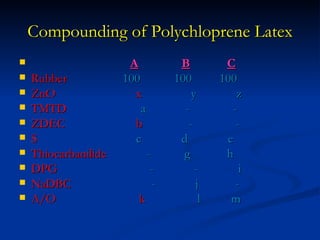

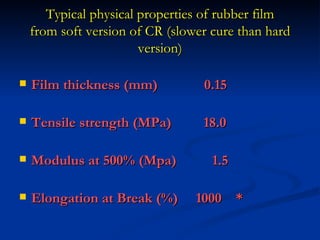

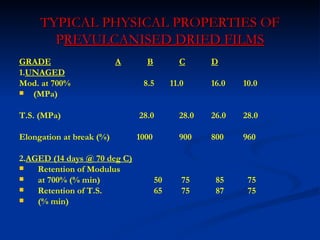

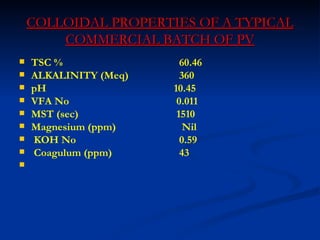

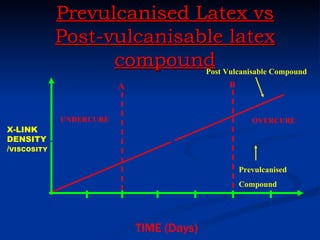

This document discusses the properties and applications of natural rubber latex and nitrile rubber, highlighting important aspects such as stability, processing differences, and latex dipping technologies. It details laxative properties, compounding methods for polychloroprene rubber, and common defects in glove production. Various technical specifications, including density, tensile strength, and modulus variations, are also provided.