This document presents an experimental investigation on reinforced concrete containing ground granulated blast furnace slag (GGBFS) as a cement replacement. Beams made of M40 grade concrete with 30% and 40% GGBFS replacement were tested under flexure. The study evaluated the performance of plain concrete and reinforced concrete beams with different reinforcement ratios. The concrete mixtures had water-cement ratios of 0.35 and 0.40. Beams were tested for compressive strength, flexural strength, splitting tensile strength, and durability at ages of 28 and 56 days. Test results are presented and discussed. The study aimed to assess how GGBFS affects the behavior and properties of reinforced concrete beams.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 06 Issue: 08 | Aug 2019 www.irjet.net p-ISSN: 2395-0072

© 2019, IRJET | Impact Factor value: 7.34 | ISO 9001:2008 Certified Journal | Page 434

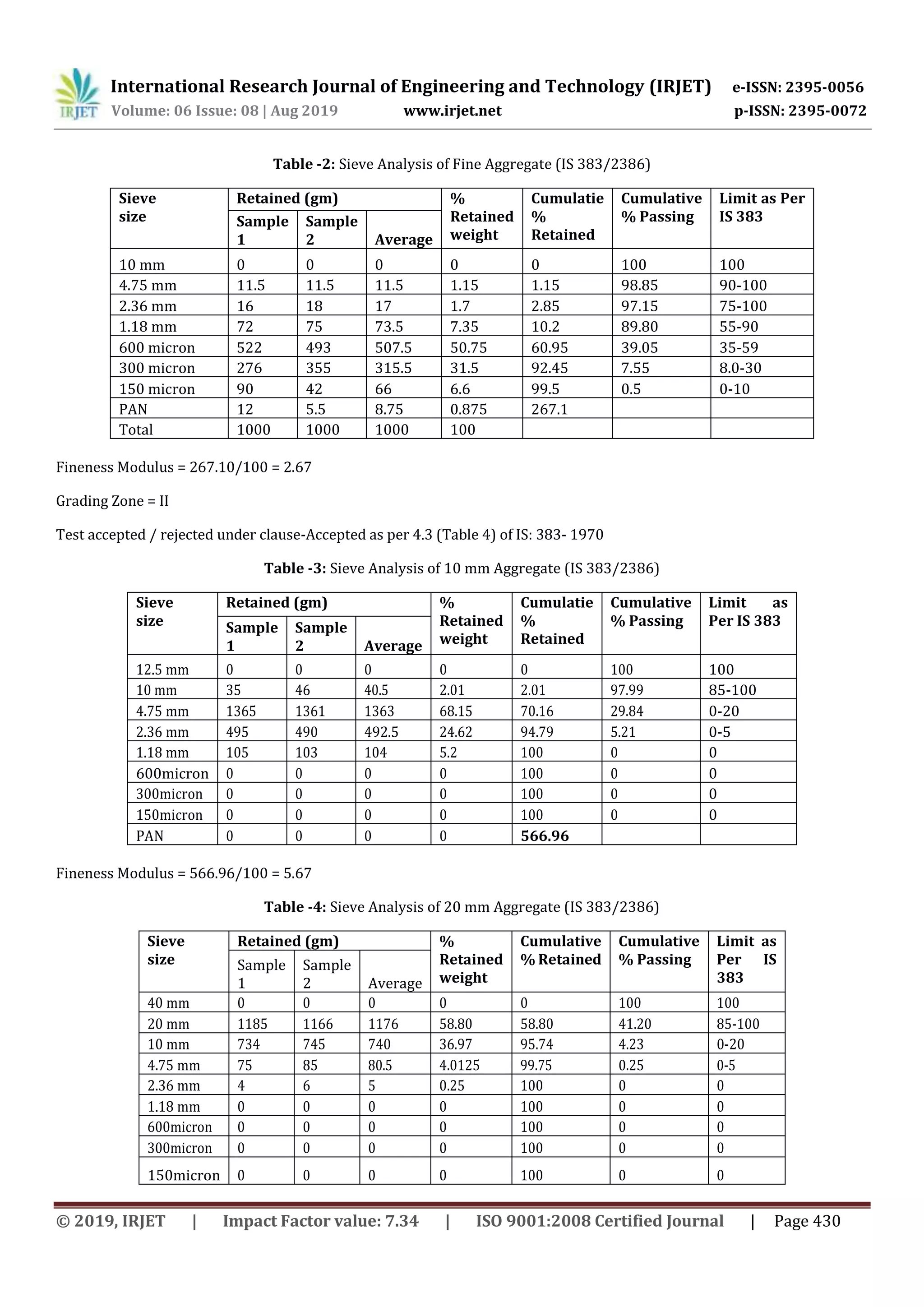

Table 7 Comparison with Different Investigators

Investigators Description

GGBFS

CONTENT

Deflection (in

mm)

(%) 28

DAYS

56

DAYS

Dr. S.P

Sangeetha

Hanger Bar

of 2#10

Tension Bar

of 3#12

Grade of

Concrete M-

35

0%

8.5-9

mm

7.5-8

mm

40%

8.1-9

mm

7.5-

8.1mm

Present Work

Hanger Bar

of 2#8

Tension Bar

of 2#10

Grade of

Concrete-40

0%

7.8-

8.2

mm

8.1-8.5

mm

40%

8.1-

8.5

8.9-9

mm

9. CONCLUSIONS

1. Partially replacing Cement with GGBFS 30% to 40% the

slump increases significantly.

2. Partially replacingCementwithGGBFS,theconsumptionof

Cement from cement production reduces significantly also

enhanced the strength (Compression, flexure and Splitting

tensile) comparison to control mix at the ages of 28 and 56

days respectively.

3. Flexural strength of plain concrete at the age of 56 days

It was observed that the flexural strength of plain concrete

beams increased in the range of 2% to 6% compared to

Control mix, with partially replacement of Cement by GGBFS

in the range of 30% to 40% respectively with 0.35 water

cement ratio.

4. Flexural strength of Reinforced concrete at the age of 28

days

It was observed that the valuesofflexuralstrengthforabeam

which is prepared with partially replacement of Cement by

GGBFS in the range of 30% to 40% and Hanger Bar and

Tension Bar taken 2#6 and 2#6 respectively and w/c ratio

0.35. The Flexural strength of reinforced beam increased in

the range of 1% to 6%

5. It was observed that the values of flexural strength for a

beam which is prepared with partially replacement of

Cement by GGBFS in the range of 30% to 40% and Hanger

Bar and Tension Bar taken 2#8 and 2#10 respectively and

w/c ratio 0.35. The Flexural strength of reinforced beam

increased in the range of 4% to 10.6%

6. Flexural strength of Reinforced concrete beam with Acid

curing (56 Days)

It was observed that the valuesofflexuralstrengthforabeam

which is prepared with partially replacement of Cement by

GGBFS in the range of 30% to 40% and Hanger Bar and

Tension Bar taken with different sets of diameter bars and

acid curing for 56 days, w/c ratio 0.35 and 0.4. The Flexural

strength of reinforced beam decreased in the range of 3% to

6% and 4% to 8% respectively compared to reinforcedbeam

of control mix.

7. Deflection in Reinforced concrete beam

A comparison of Deflection test results of the present study

with those reported by other investigators at the age of 28

and 56 days, lie in the almost same range of the results given

by other investigators.

REFERENCES

[1] V. Johnpaul, N. Balasundharam, S. Sanothini.

Pragadheesh , Kameshwaran J, Satheesh kumar M, M.

Balajimanikandan, " An Experimental Study on Flexural

Behaviour of Nano Ggbfs Concrete", International

Journal of Recent Technology and Engineering (IJRTE),

Volume-7, Issue-6S5,PP-1744-1747, April 2019.

[2] Dr. Shankar H. Sanni and Keshavraj. Girinivas,

"Analytical Investigations on Reinforced Concrete

Beams", International Research Journal of Engineering

and Technology (IRJET), Volume-05,Issue-12,PP-1509-

1513, Dec 2018.

[3] P. Rama Mohan Rao and S. Karthik," Investigation on

Flexural Behaviour of Beam with Bamboo as Main

Rebars",International Journal of RecentTechnologyand

Engineering (IJRTE), ISSN: 2277-3878, Volume-7 Issue-

4S2, PP- 173-177, December 2018.

[4] Rathan Raj R, Ganesh Prabhu G and Perumal Pillai E B, "

Flexural Behavior of Concrete Beam with GGBS and Fly

Ash as Supplementary Cementitious Material",

International Journal of Applied Engineering Research,

Vol-10, No-47, PP-32310-32315, 2015.

[5] B.Kaviya.R, Arjun, Rajkumar. P, Ramakrishnan. S and

Subash. S, "Study on Partial Replacement Of Cement By

Ground Granulated Blast Furnace Slag (GGBS)",

International Journal of Pure and Applied Mathematics,

Vol-116, No-13, PP-411-416, 2017.

[6] Divyadevi Sundaravadivel and Dr. R. Mohana, "Recent

Studies of Sugarcane Bagasse Ash in Concrete and

Mortar- A Review", International Journal ofEngineering

Research & Technology (IJERT),Vol.7,Issue04,PP-306-

312, April 2018.](https://image.slidesharecdn.com/irjet-v6i8110-191128094447/75/IRJET-An-Experimental-Investigation-on-Reinforced-Concrete-Containing-GGBFS-7-2048.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 06 Issue: 08 | Aug 2019 www.irjet.net p-ISSN: 2395-0072

© 2019, IRJET | Impact Factor value: 7.34 | ISO 9001:2008 Certified Journal | Page 435

[7] J.Vengadesh Marshall Raman and V.Murali Krishnan,

“Partial Replacement of Cement with GGBS in Self

Compacting Concrete for Sustainable Construction",

SSRG International Journal of Civil Engineering ( SSRG –

IJCE ), Volume 4, Issue 3, PP-22-25, March 2017.

[8] Sonali K. Gadpalliwar, R. S. Deotale and Abhijeet R.

Narde, "To Study the Partial Replacement of Cement by

GGBS & RHA and Natural Sand by Quarry Sand In

Concrete", IOSR Journal of Mechanical and Civil

Engineering (IOSR-JMCE), Volume 11, Issue 2, Ver. II,

PP-69-77, Mar- Apr. 2014.

[9] Mr. P. Brightson, Mr. M. Prem Anand and Dr. M. S.

Ravikumar, "Flexural Behavior of Beams Incorporating

GGBS as Partial Replacement of Fine Aggregate in

Concrete", Advanced Materials Research Vols-984-985,

PP-698-706, 2014.

[10] Mrs. S. P. Sangeetha and Dr. P. S. Joanna, "Flexural

Behaviour of Reinforced Concrete Beams With GGBS",

International Journal of Civil Engineering and

Technology (IJCIET),Volume-5, Issue-3, PP-124-131,

March 2014.

[11] Dattatreya J K, Rajamane NP, Sabitha D, Ambily P S and

Nataraja MC, "Flexural behavior of reinforced Geo

polymer concrete beams", International Journal Of Civil

And Structural Engineering, Volume-2, No-1, PP-138-

159, 2011.

[12] Chithra P, Naveen Kumar A B, Vivekananthan V,

"Experimental Study on Structural behaviour of

reinforced concrete beams containing Sisal fiber and

GGBS", International Journal of Multidisciplinary

Research Transactions", Volume-1, Issue-3, PP-22-30,

May 2019.

[13] Dr. S. P. Sangeetha, "Strength and Flexural Behaviour Of

Reinforced Concrete With Ground Granulated Blast

Furnace Slag", International Journal ofPureandApplied

Mathematics, Volume-118, No-5, PP-867-879, 2018.

[14] Dr. B. Vidivelli, M. Gopinath andT.Subbulakshmi,"Study

on flexural behaviour of reinforce concrete beam with

GGBS and steel fibre", International Journal of Scientific

& EngineeringResearch,Volume-7,Issue-6,PP-719-730,

June-2016.](https://image.slidesharecdn.com/irjet-v6i8110-191128094447/75/IRJET-An-Experimental-Investigation-on-Reinforced-Concrete-Containing-GGBFS-8-2048.jpg)