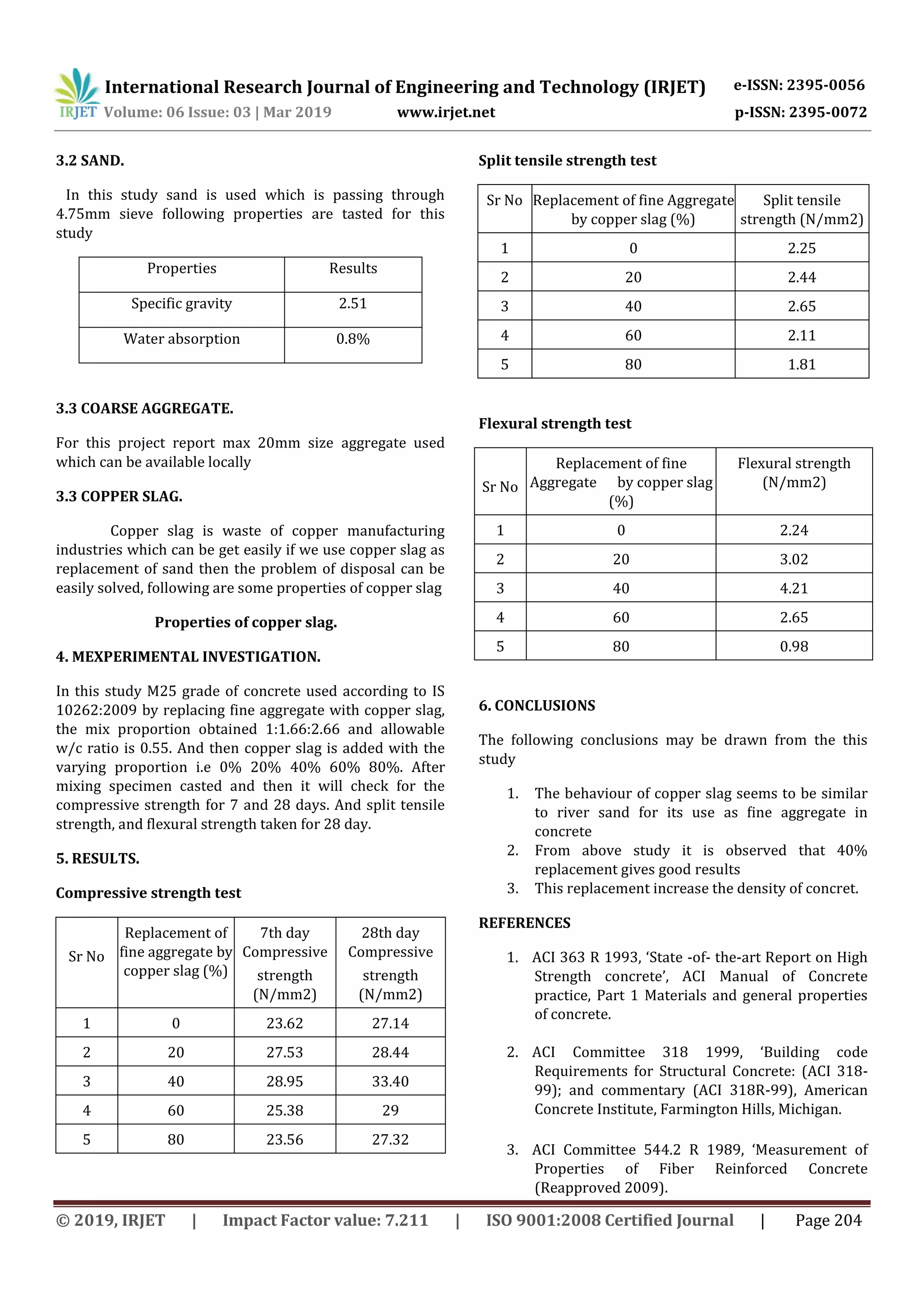

This document presents a study that investigated using copper slag as a partial replacement for fine aggregate in concrete. Various concrete mixtures were made with 0%, 20%, 40%, 60%, and 80% replacement of fine aggregate with copper slag. The compressive strength, split tensile strength, and flexural strength of the concrete mixtures were tested at 7 and 28 days. The results showed that 40% replacement of fine aggregate with copper slag produced concrete with the highest strengths. Using copper slag as a partial replacement increased the density of the concrete. The study concluded that copper slag can be effectively used as a replacement for fine aggregate in concrete.