1) The study evaluated the use of reclaimed asphalt pavement (RAP) material in the sub-grade layer of flexible pavements in Vidisha City.

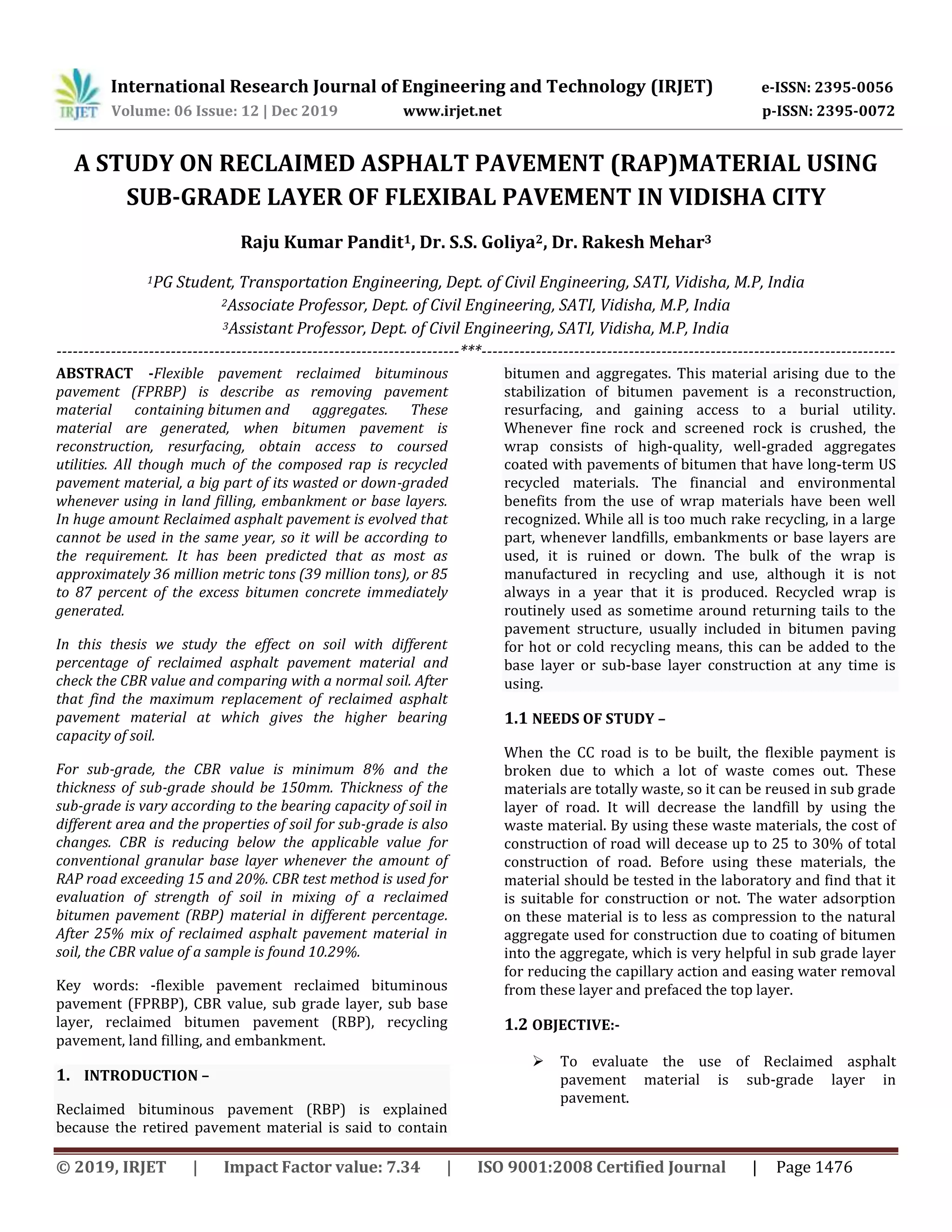

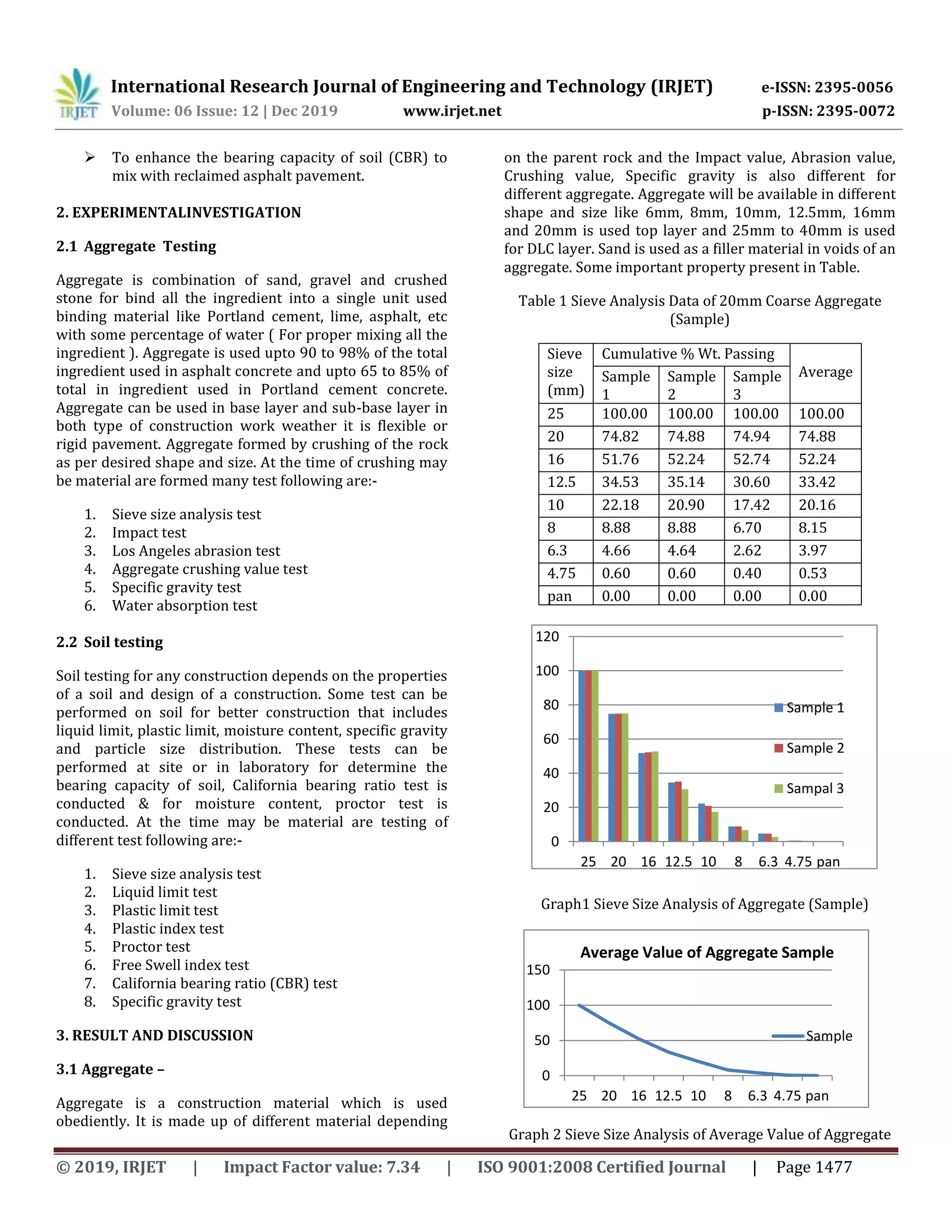

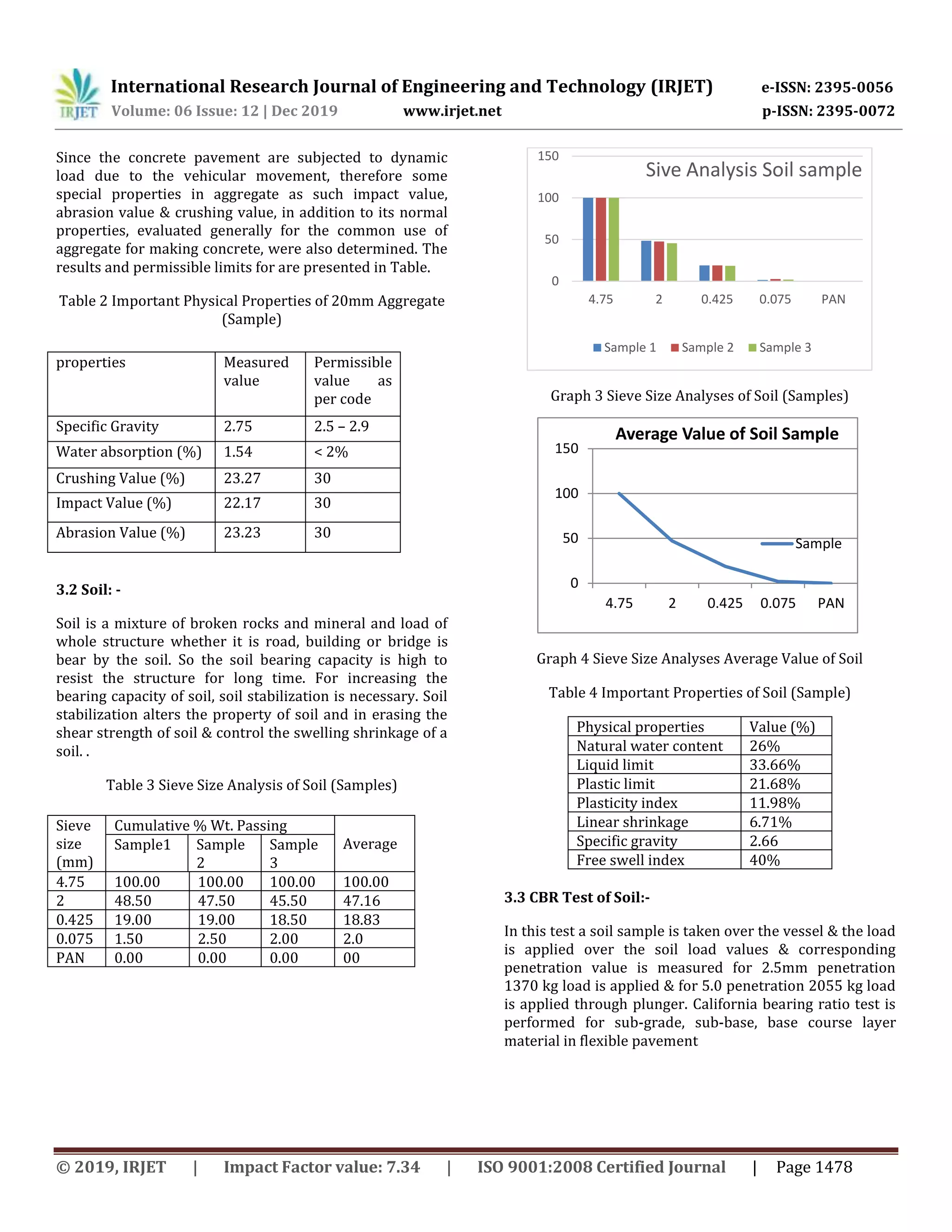

2) Tests were conducted on soil samples mixed with different percentages of RAP material to determine the California bearing ratio (CBR) value and compare it to normal soil.

3) The results showed that mixing soil with 25% RAP material increased the CBR value to 10.29%, higher than the minimum 8% required by codes, indicating that RAP material can improve the bearing capacity of soil for use in sub-grade layers.