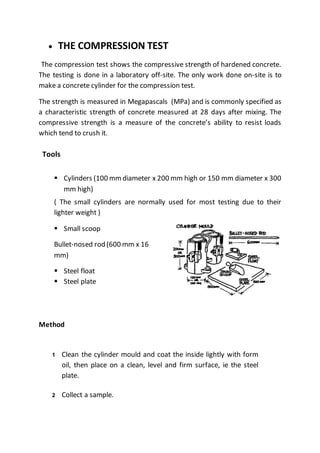

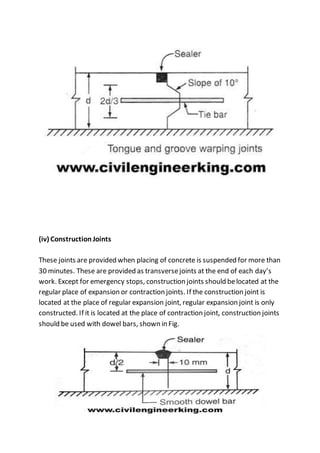

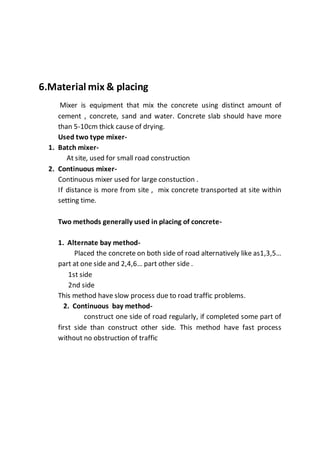

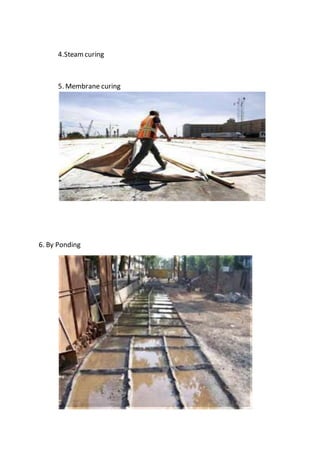

The document provides details about Vijaypal Bagariya's 15-day summer training report on cement concrete road construction with the Public Works Department (PWD) in Rajasthan from May 15th to July 14th, 2017. It includes an acknowledgment, introduction to the PWD and cement roads, description of materials used (cement, sand, aggregate), common tests on concrete (slump test, compression test, impact test, cube test), and steps for cement road construction (preparation of subgrade, base, formwork, placing, compaction, finishing, curing). The report is submitted to Mr. Yogesh Agarwal and provides information gathered during Vijaypal's training experience with the P