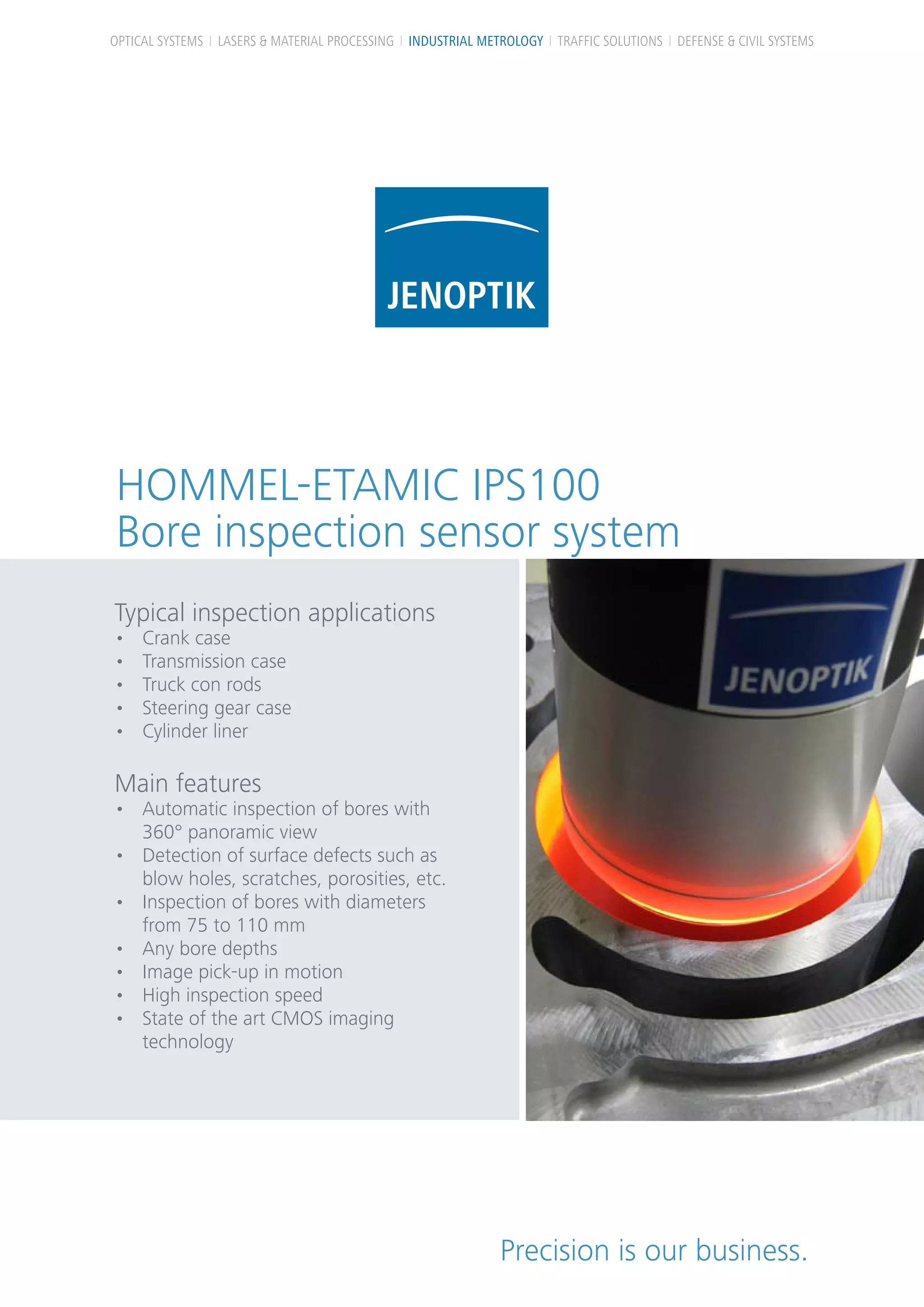

The document describes the Hommel-Etamic IPS100 bore inspection sensor system. The IPS100 can automatically inspect bores with diameters between 75-110mm, any bore depth, and detect surface defects while moving. It uses a 360 degree circular optics to generate undistorted images of the bore's inner surface and high-speed CMOS imaging to quickly scan the bore. The IPS100 system configuration includes the bore sensor, light source, framegrabber, linear axis, and PC software for automatic image analysis.