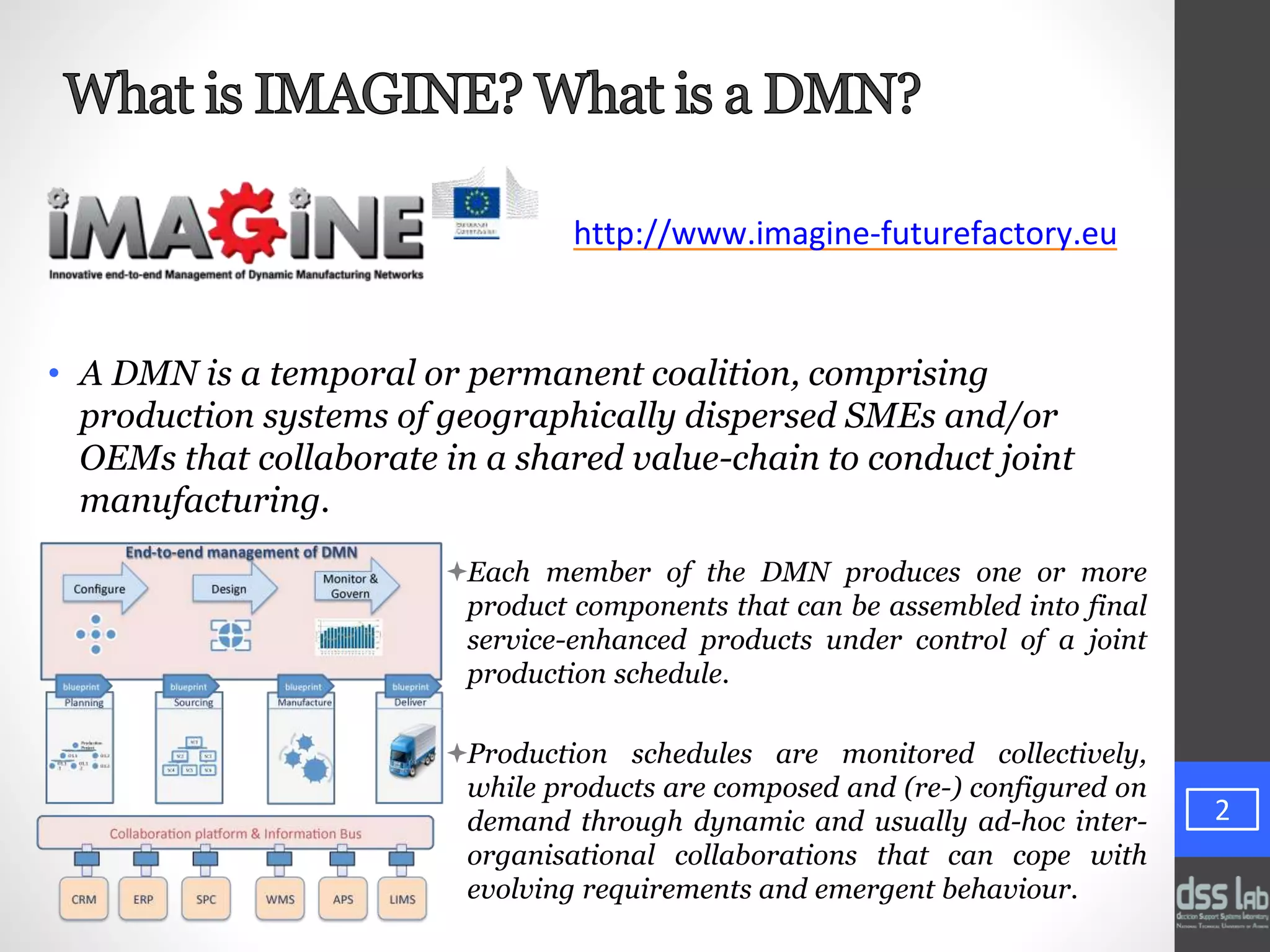

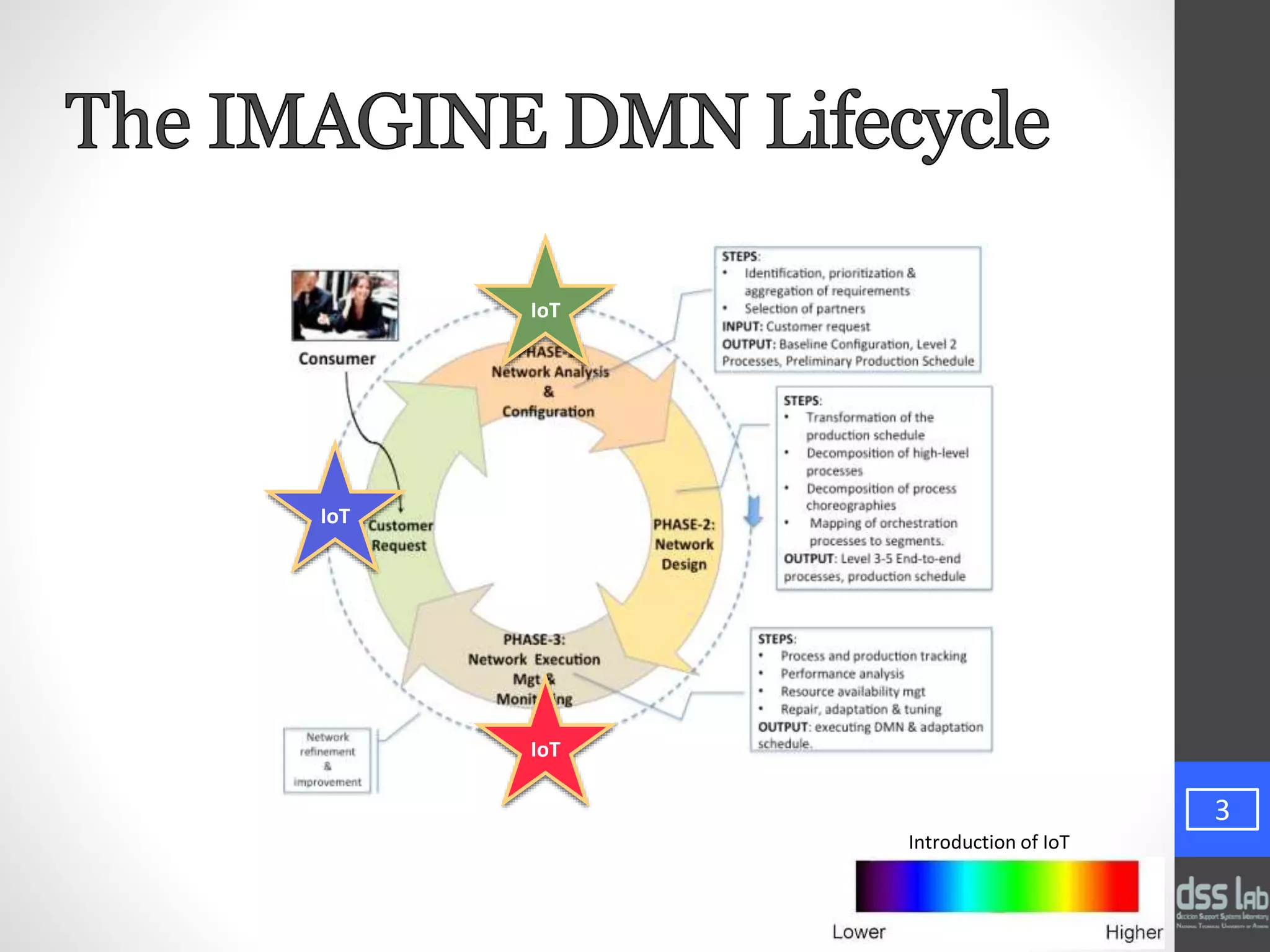

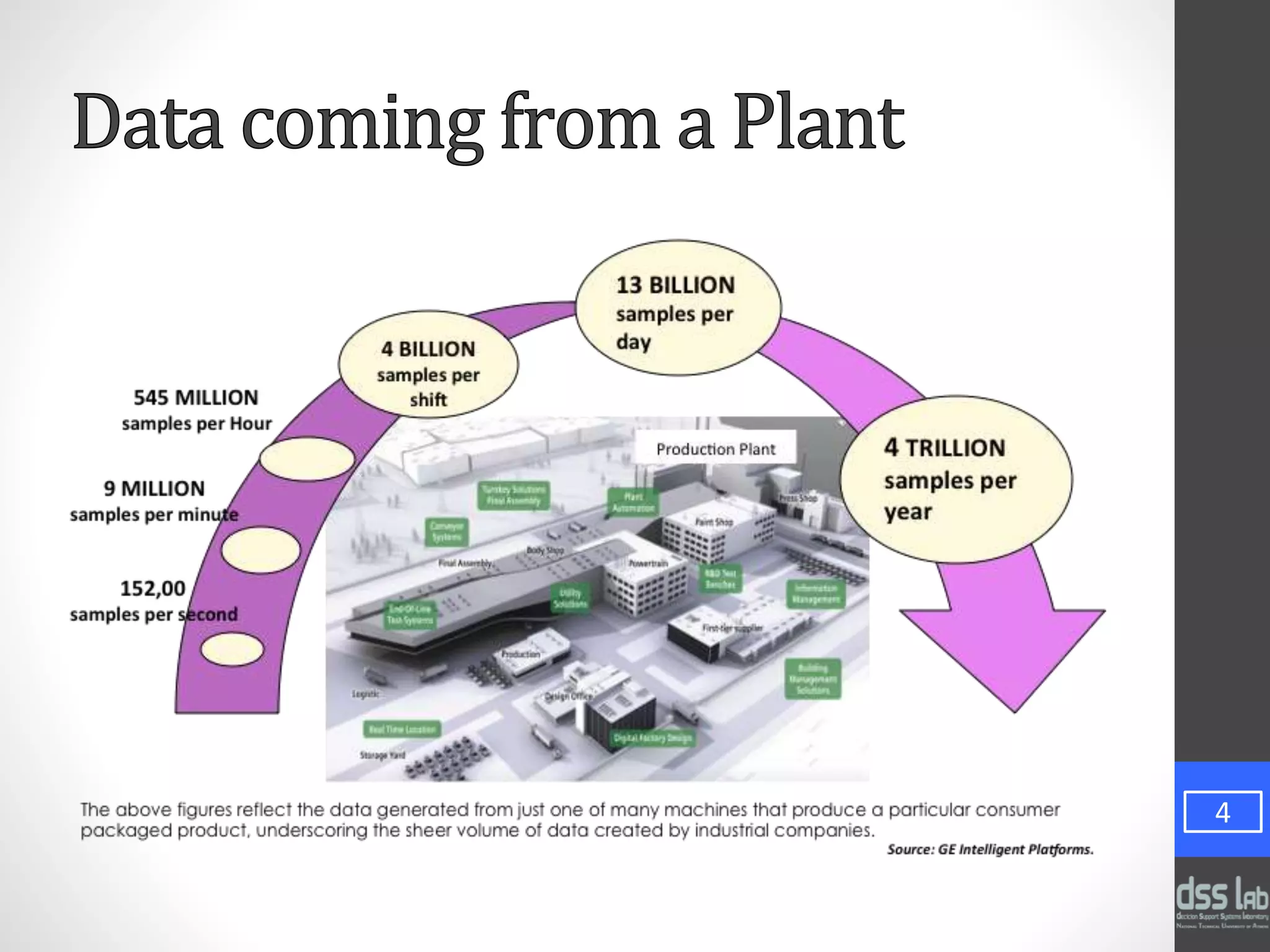

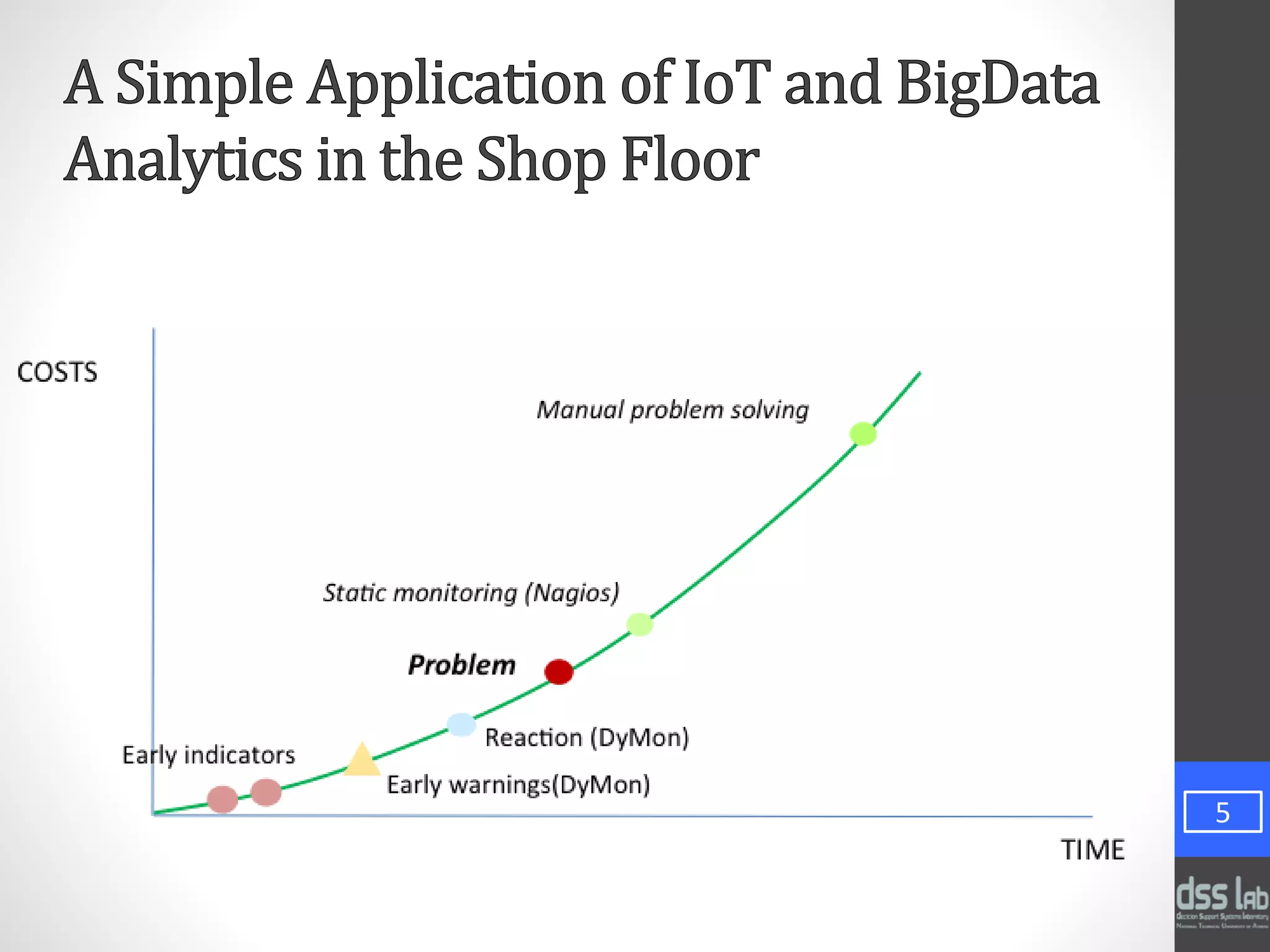

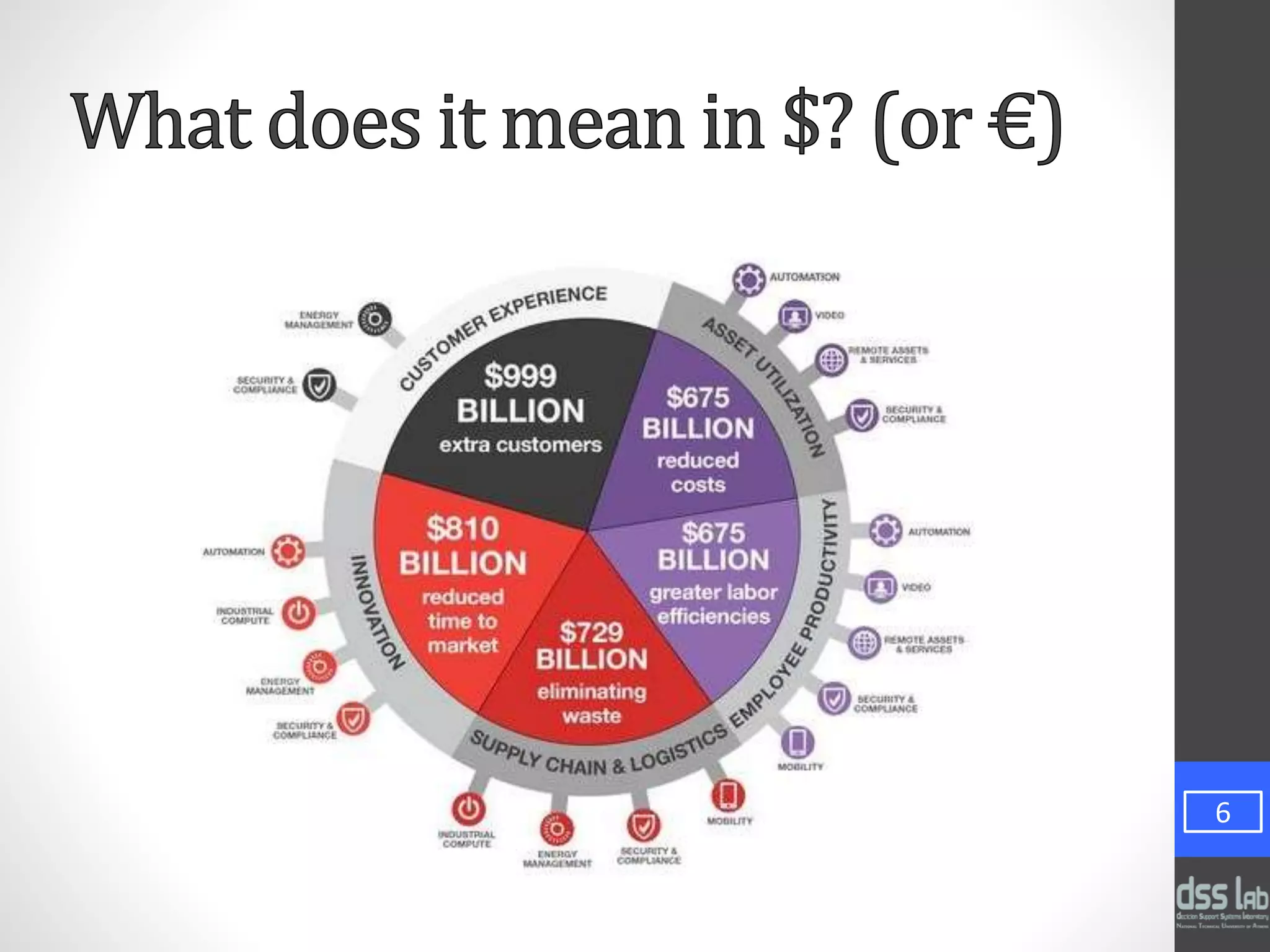

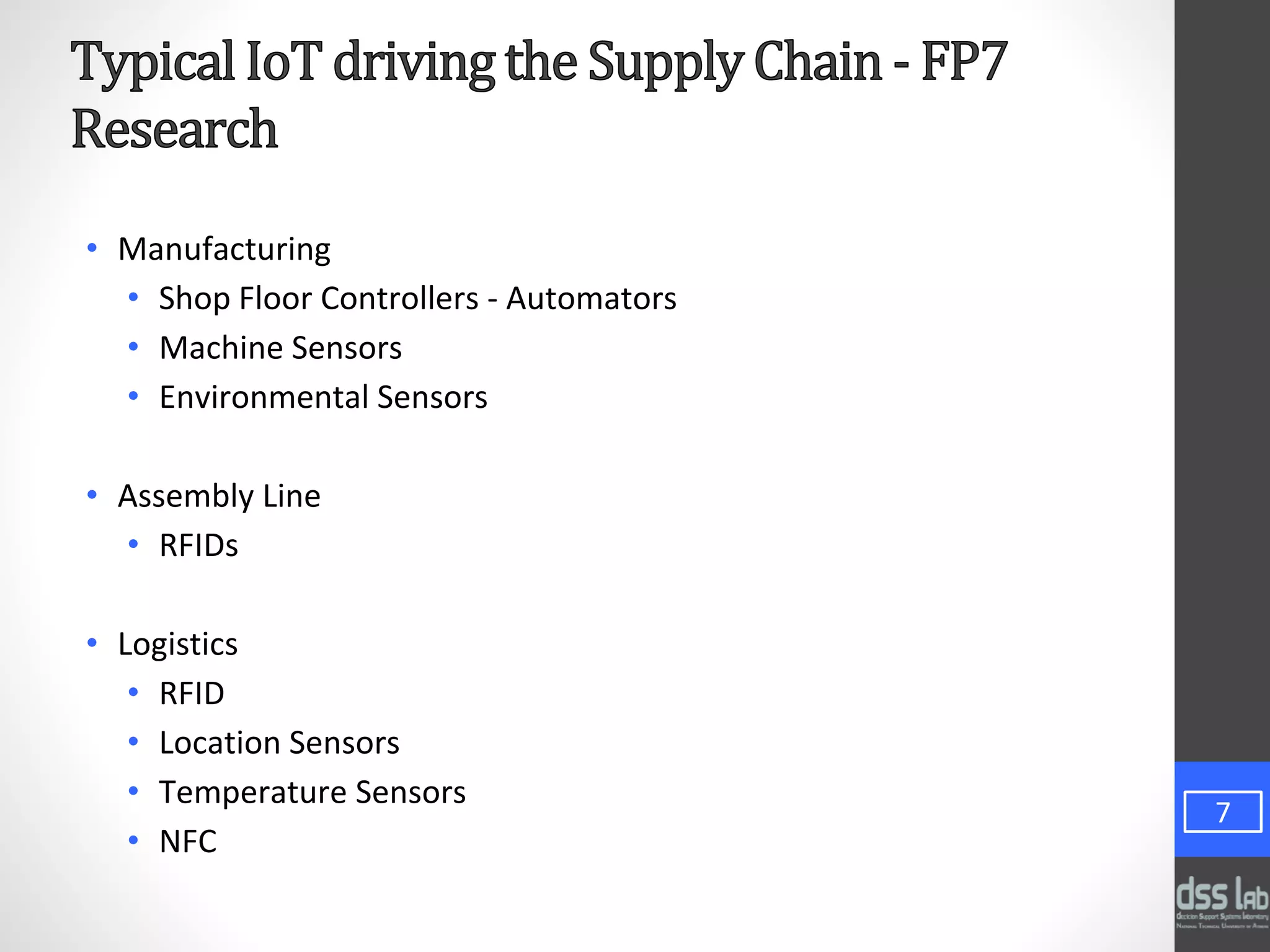

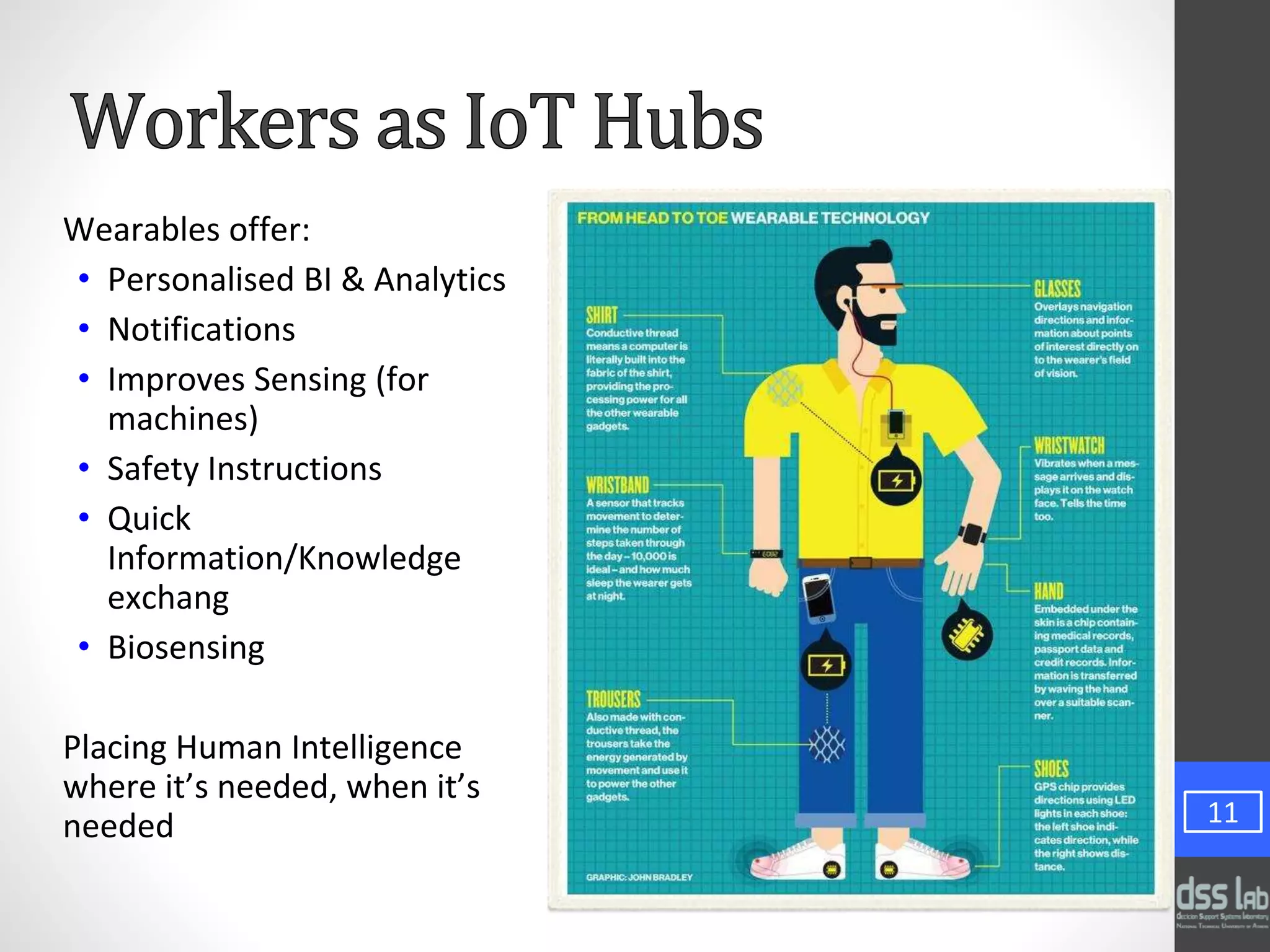

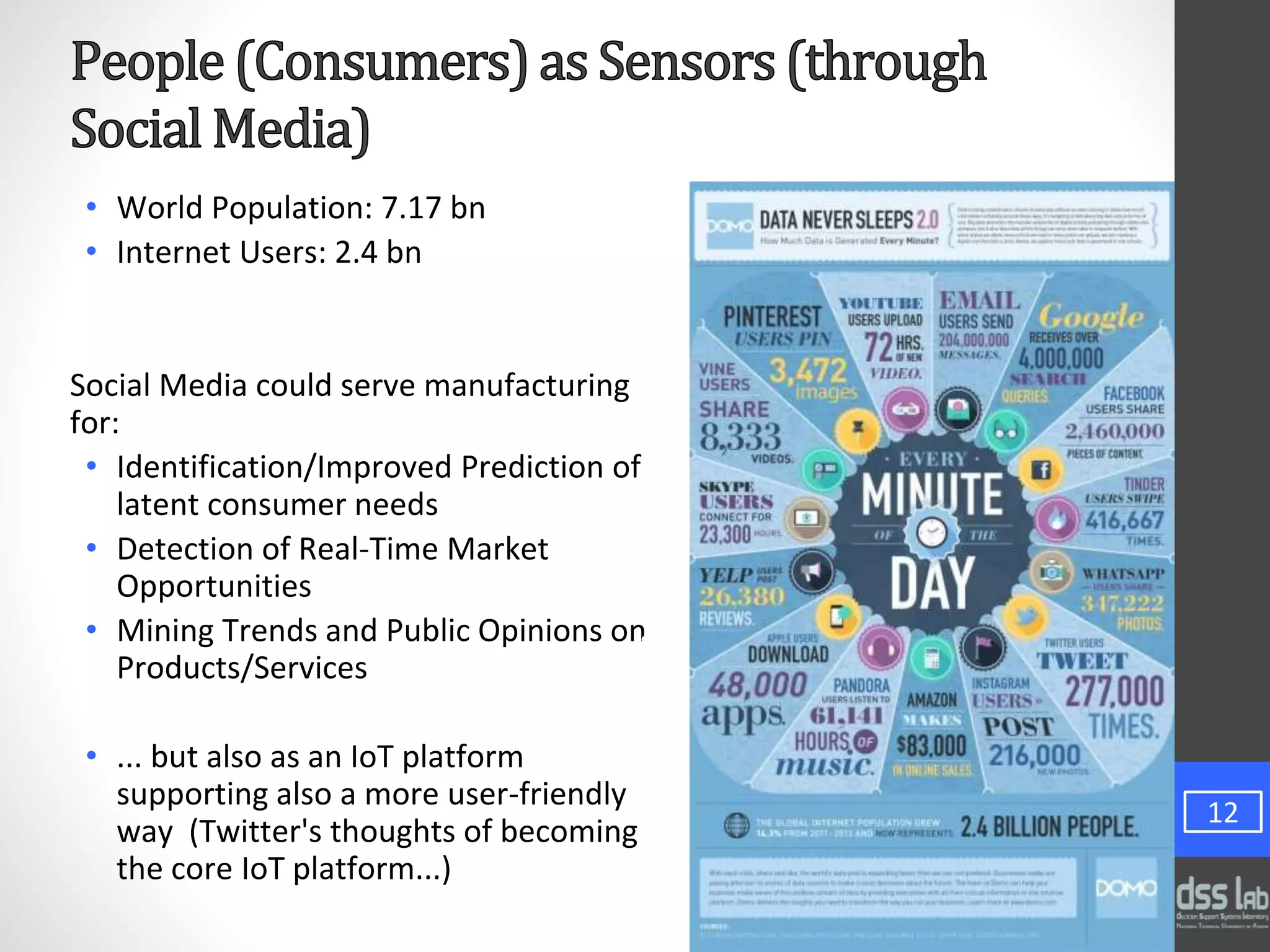

The document discusses how distributed manufacturing networks (DMNs) can utilize internet of things (IoT) technologies. DMNs involve geographically dispersed small- and medium-sized enterprises collaborating on a shared value chain. IoT sensors on machinery, environmental conditions, RFID tags, and other devices can monitor production schedules and compose products on demand. While many IoT technologies exist, combined usage remains limited by interoperability issues. Fully integrating manufacturing data from IoT networks with historical logs could enable real-time processing. Making products and components "smart" through multi-objective devices that collaborate could further optimize factory goals like efficiency. The cloud can help control and provide resources for interconnected IoT and sensor grids.