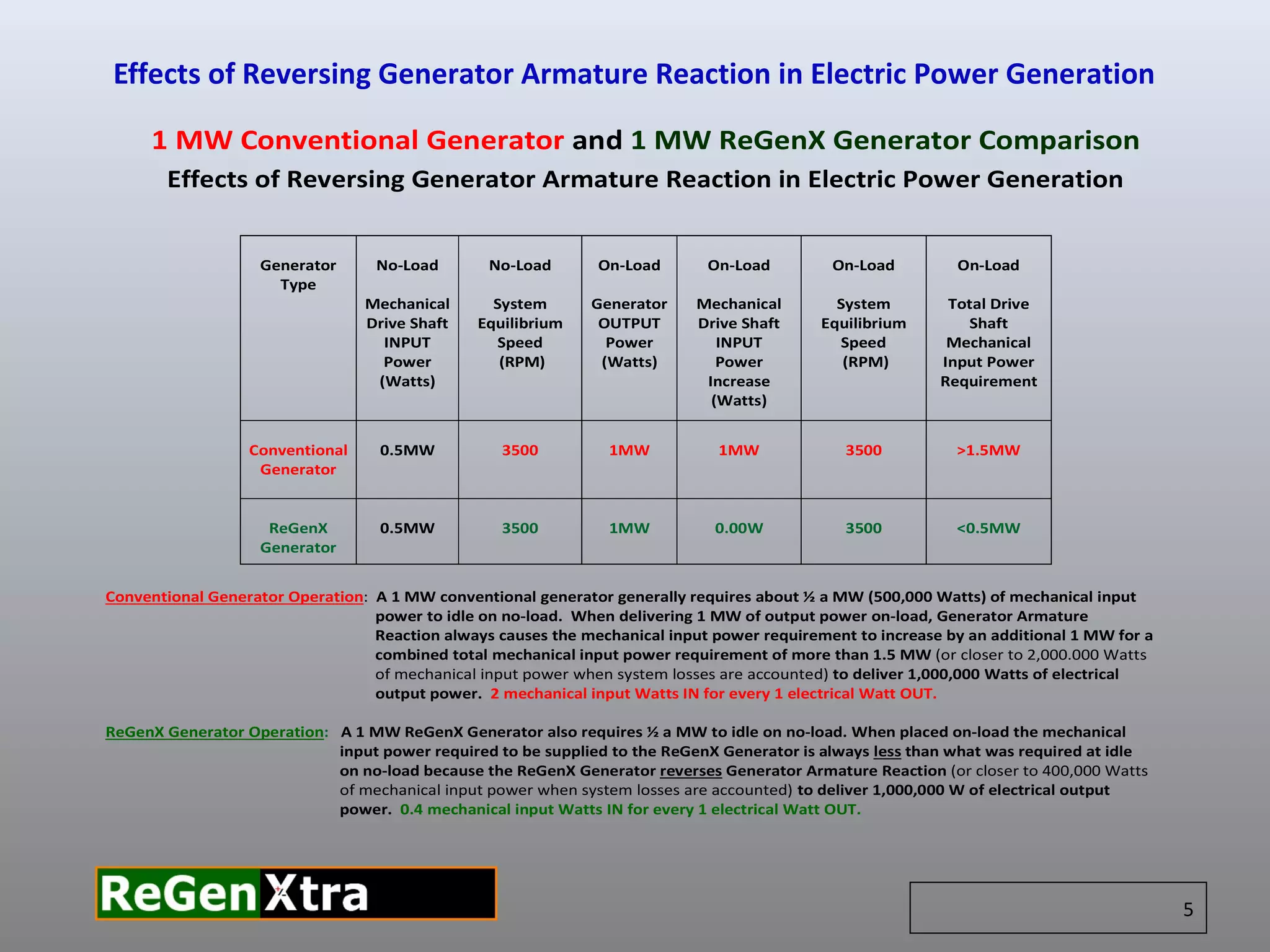

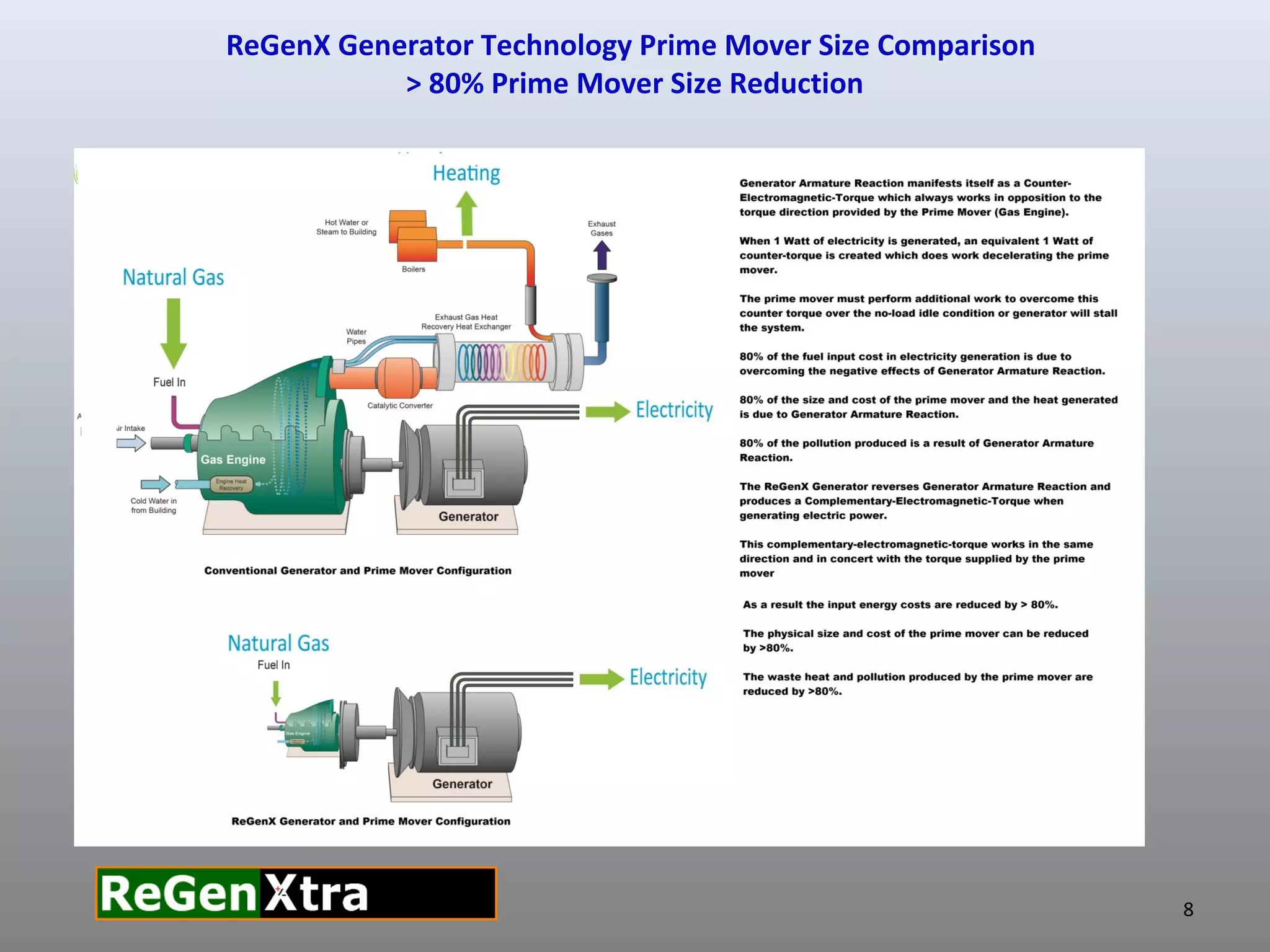

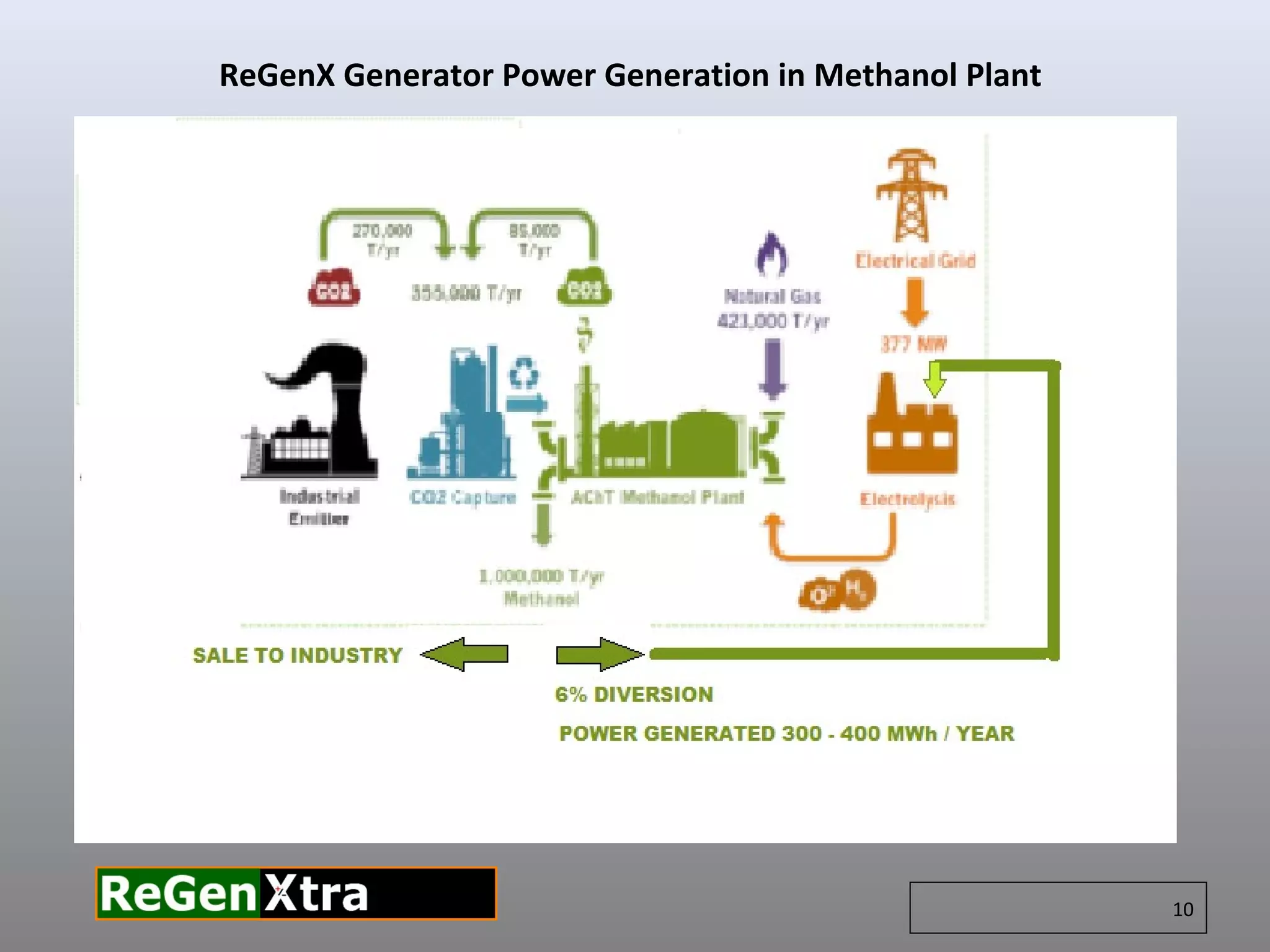

The document describes Potential +/-Difference Inc.'s ReGenX Generator and electric vehicle regenerative acceleration innovations. The ReGenX Generator reverses generator armature reaction, reducing electricity generation costs by over 80%. For electric vehicles, regenerative acceleration recharges batteries during acceleration instead of deceleration. Commercialization plans include developing 30MW and 800MW ReGenX Generators for a methanol plant by 2030. Siemens, GE, and Westinghouse may provide scale-up services.