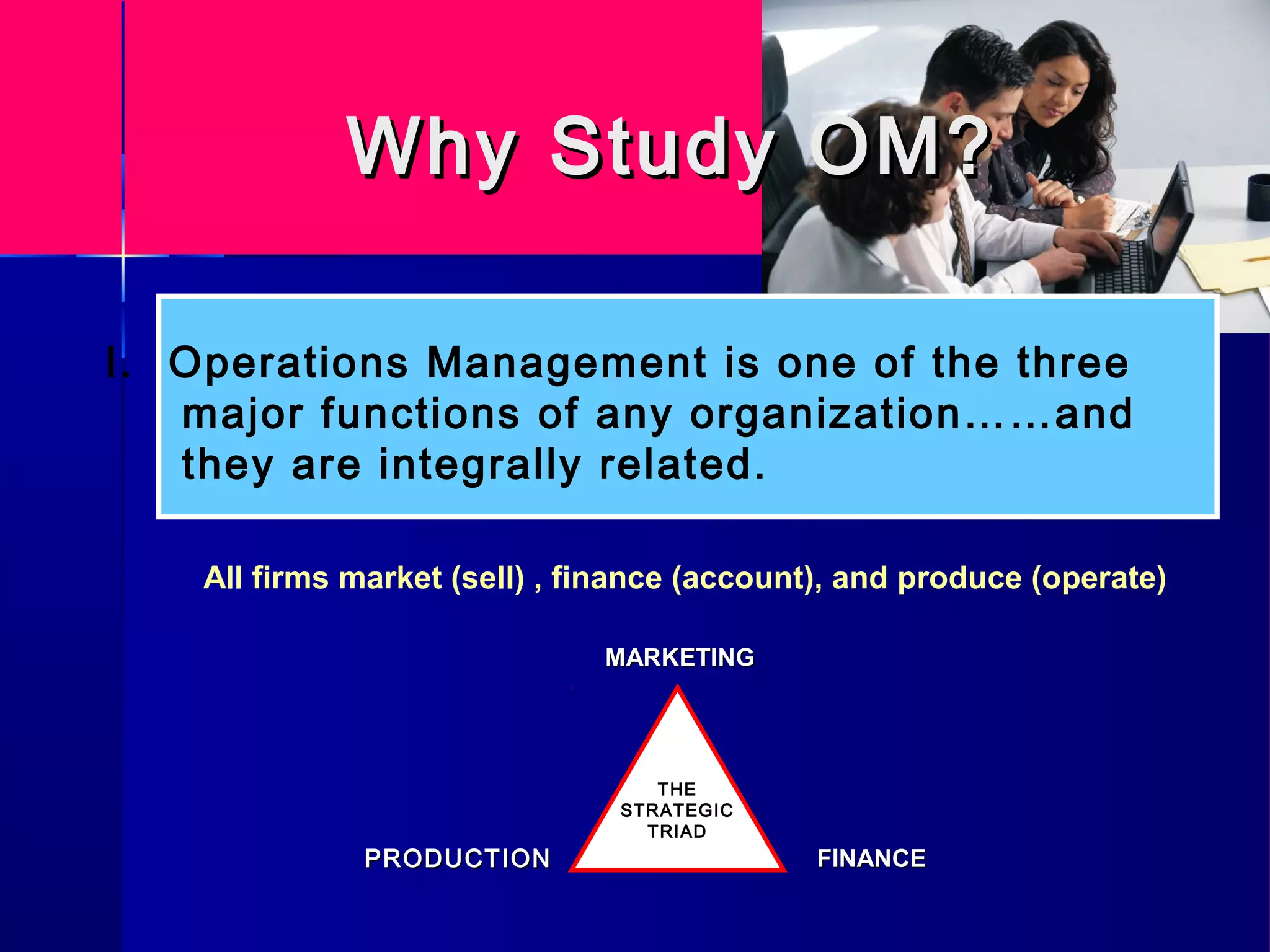

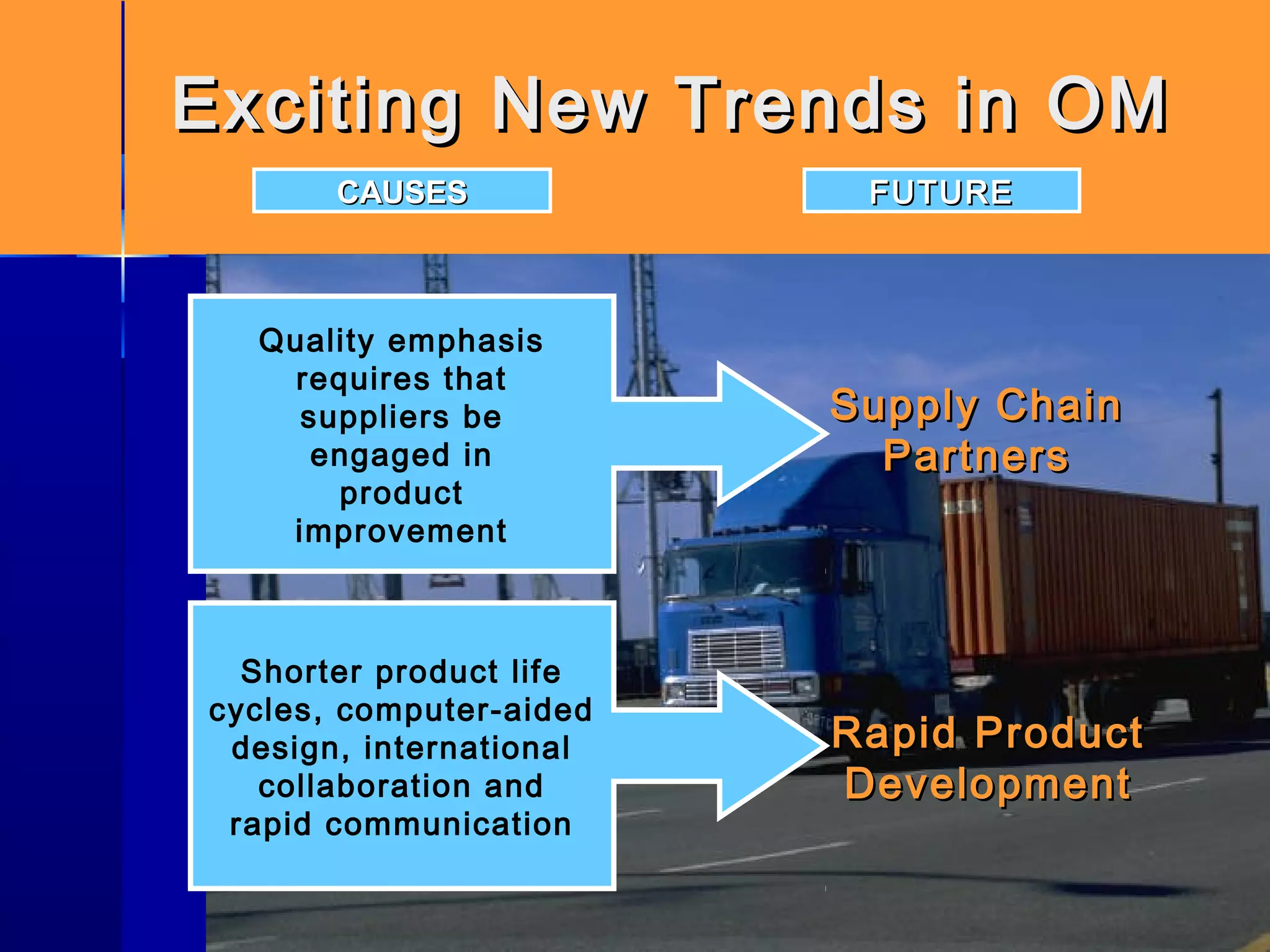

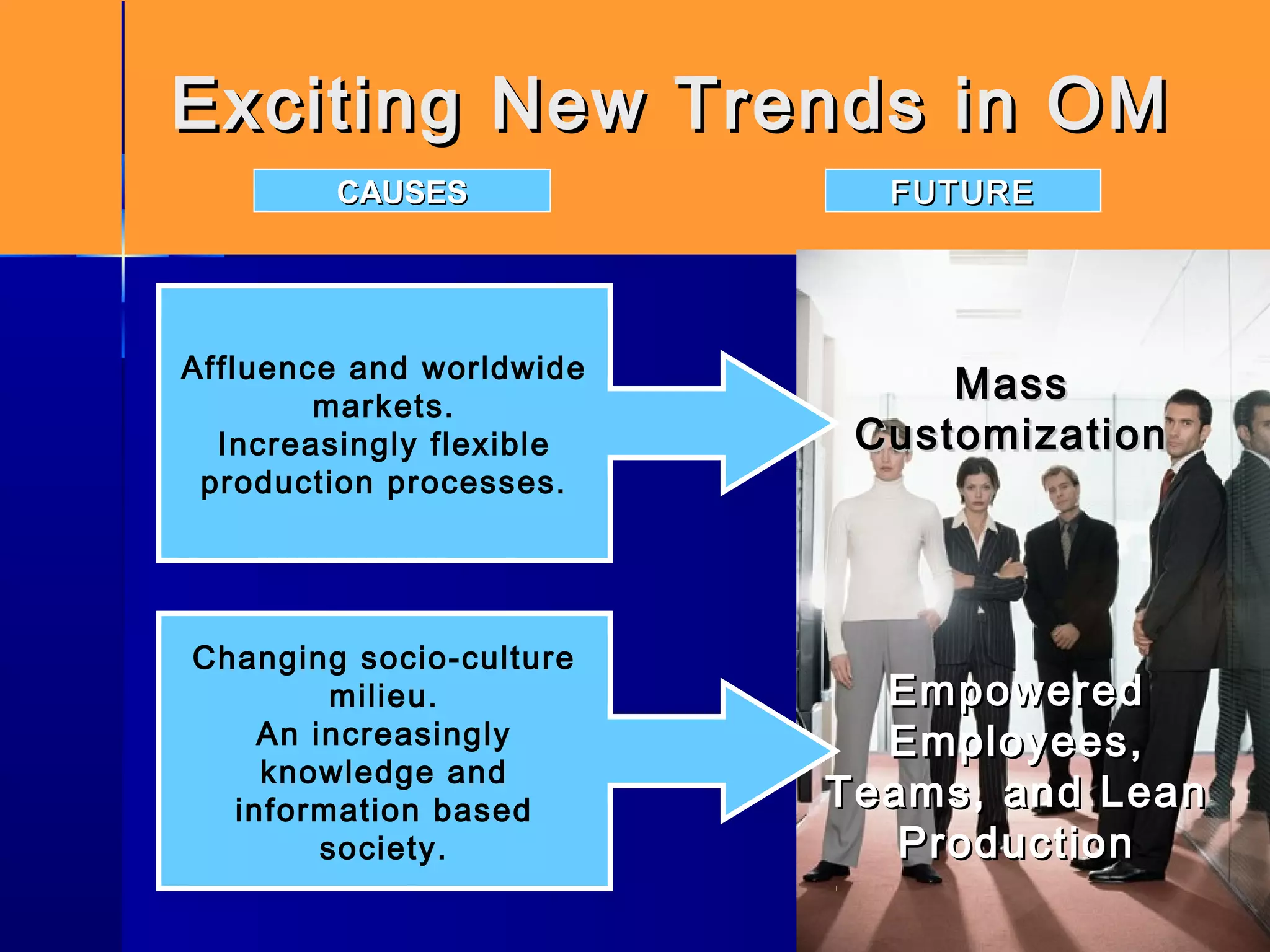

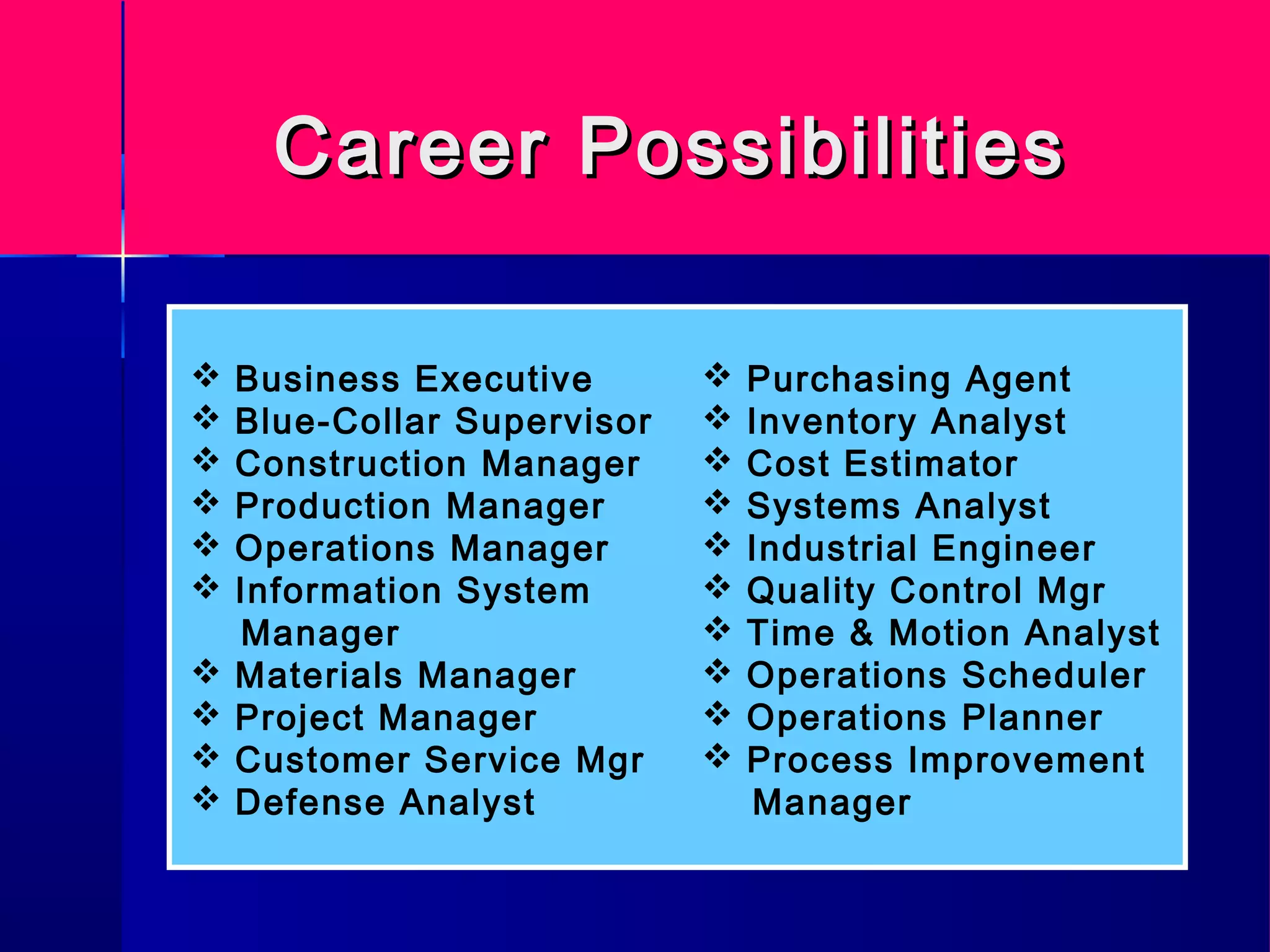

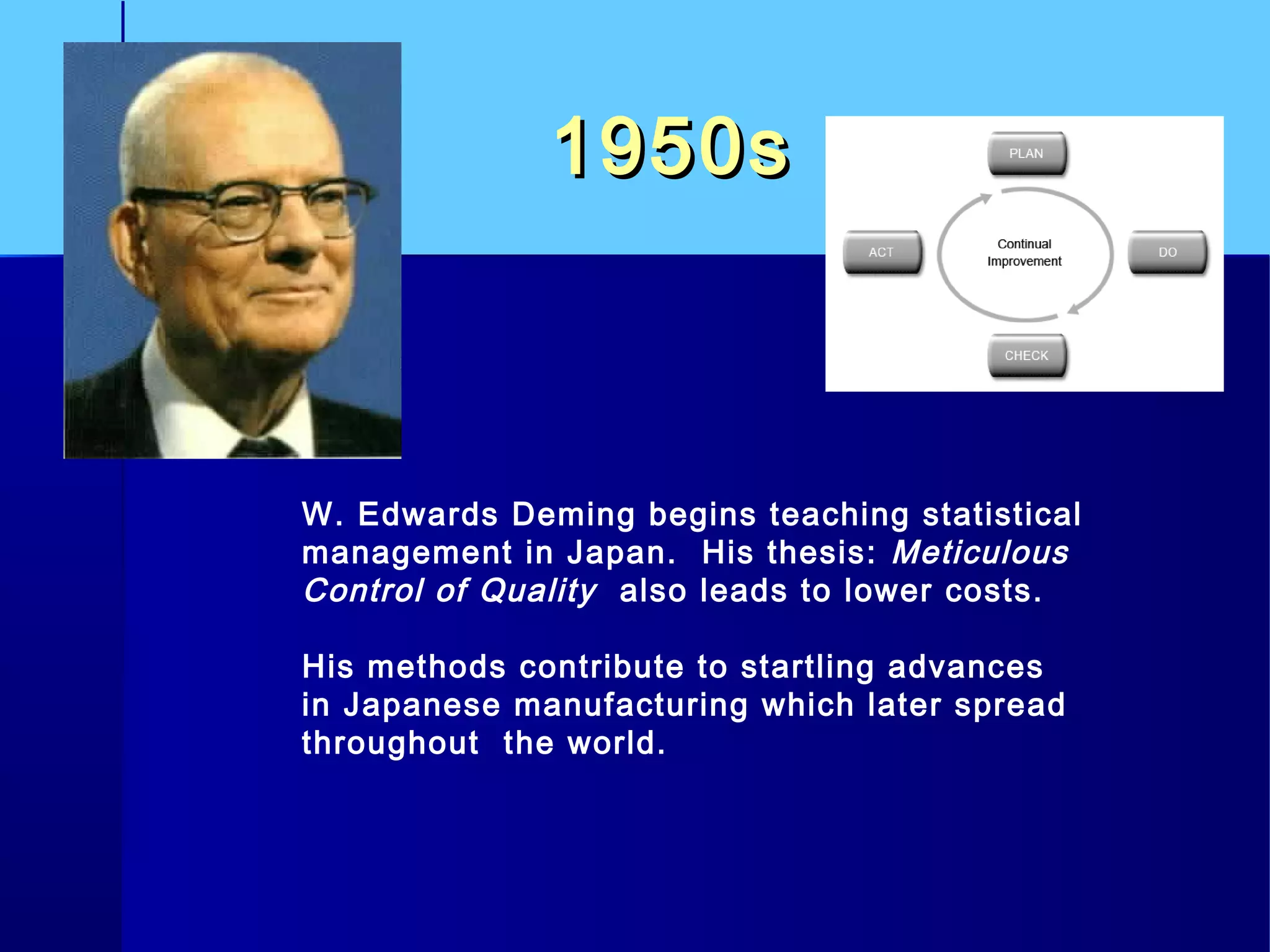

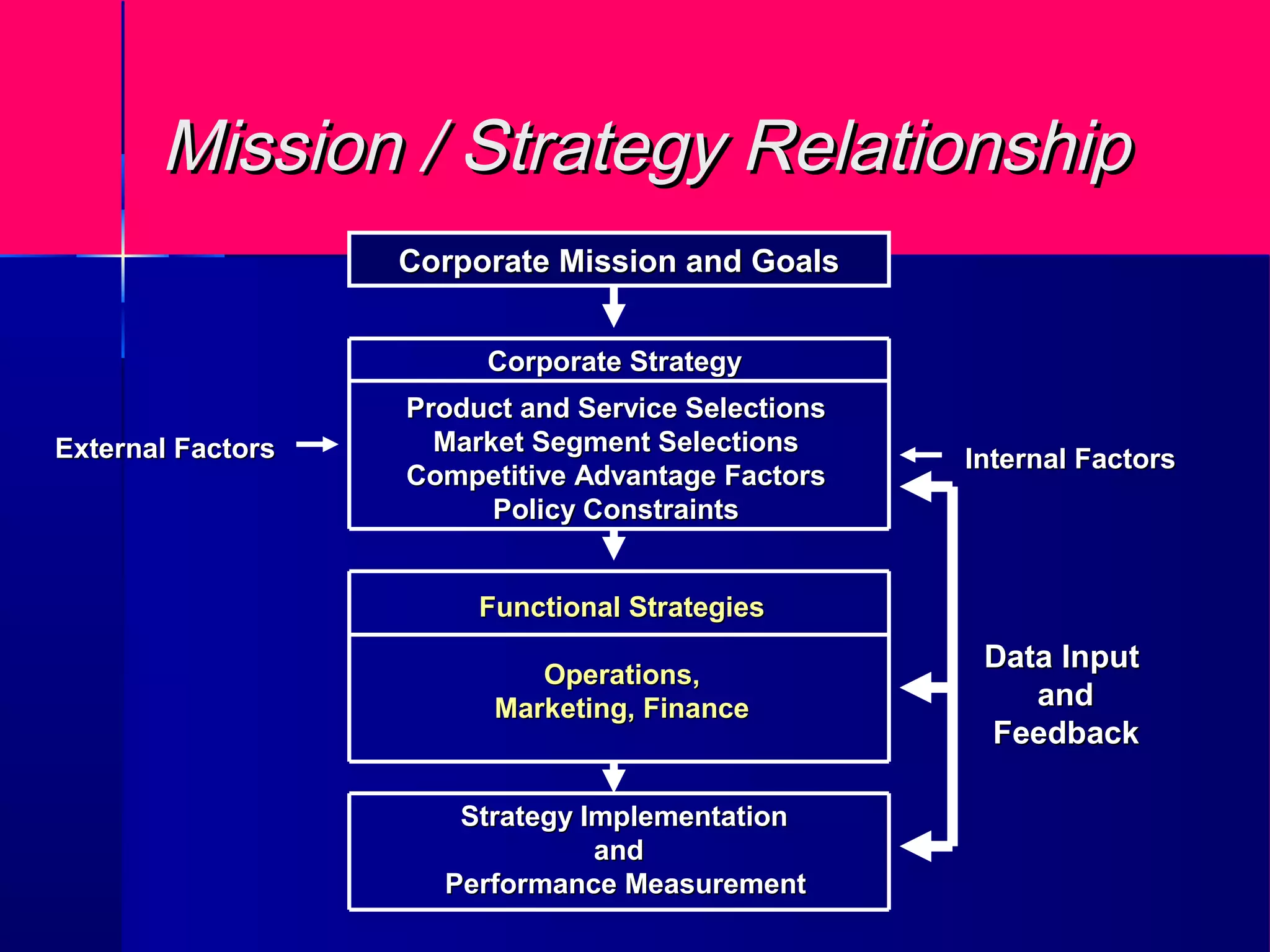

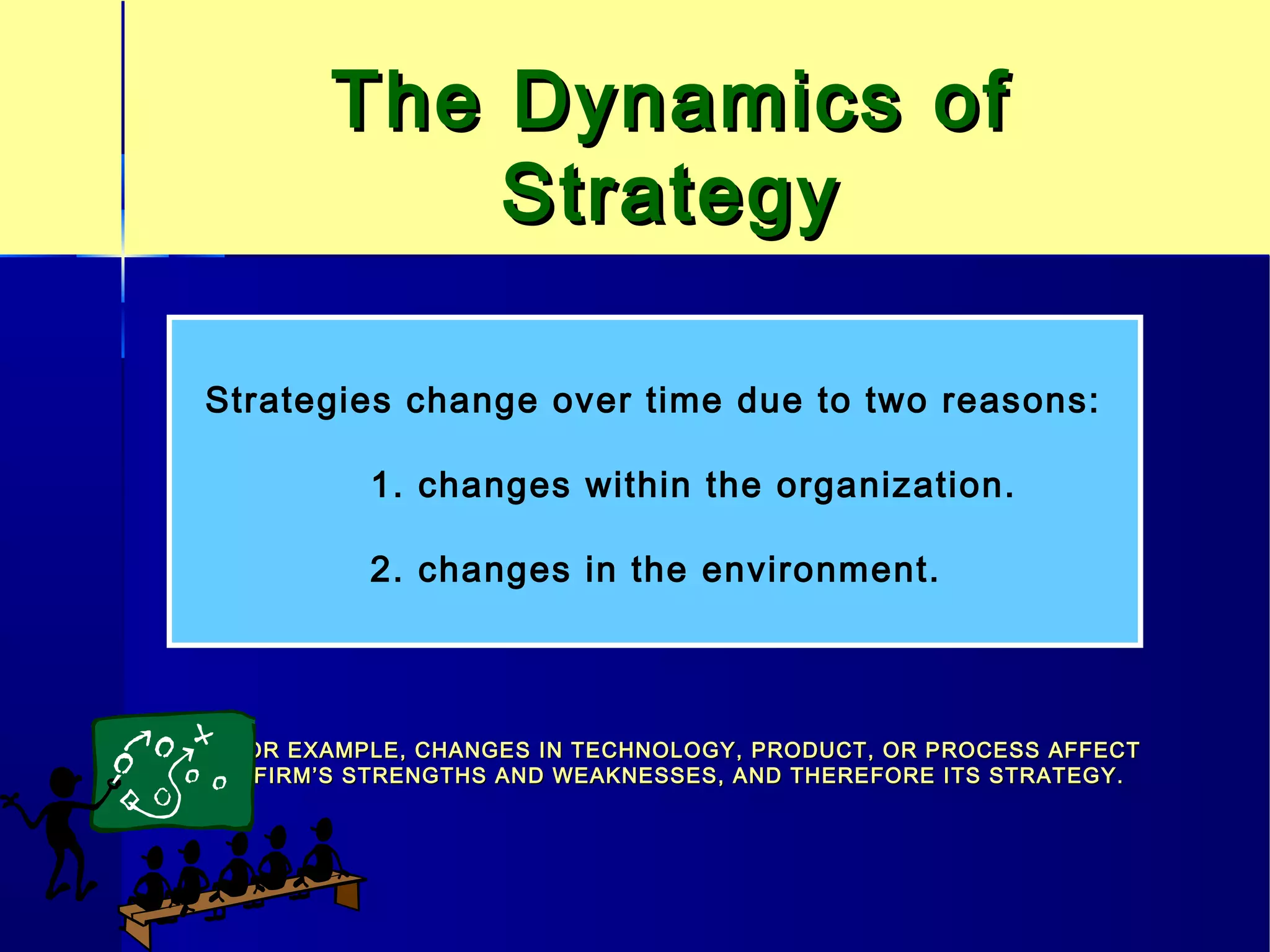

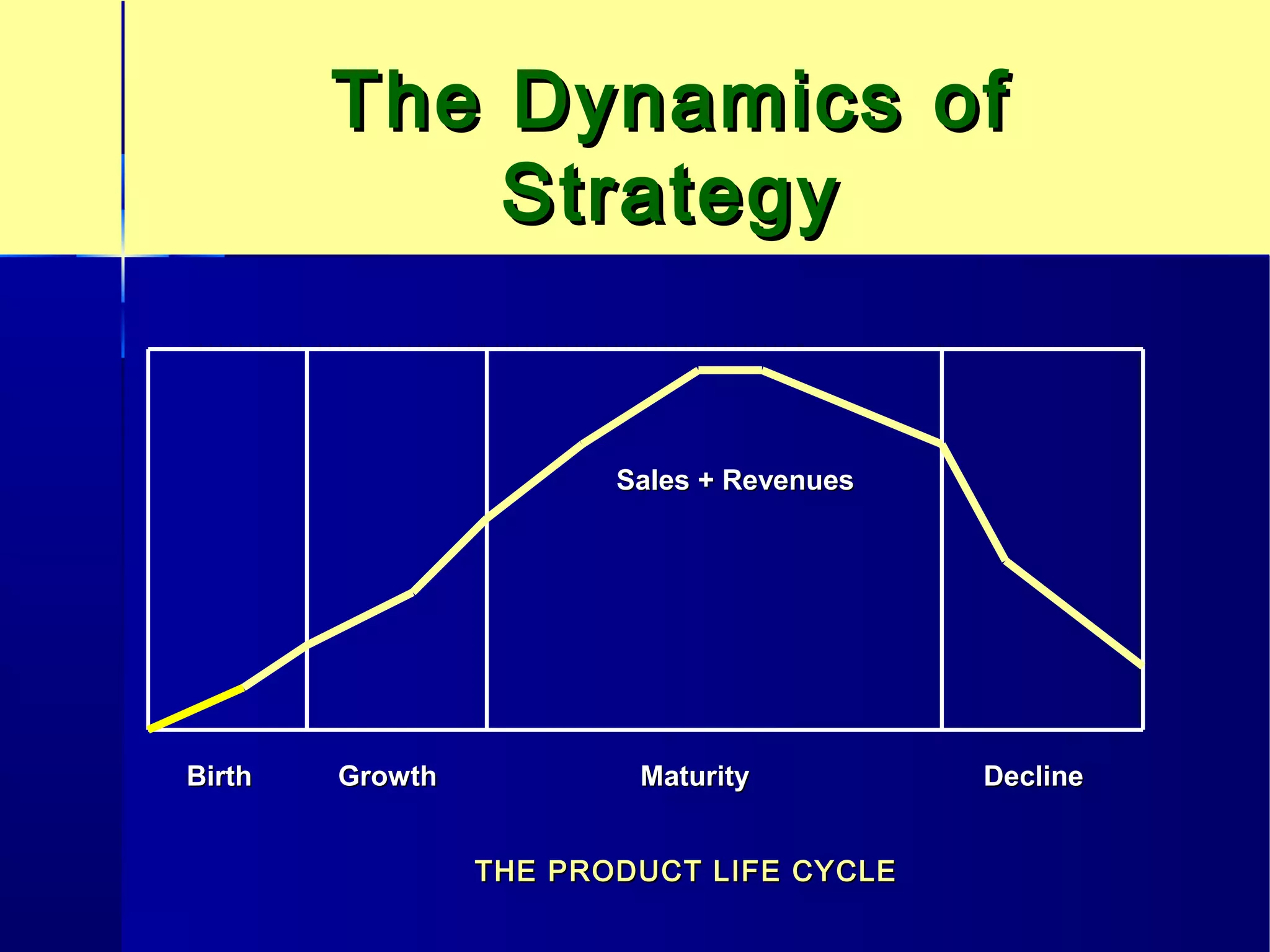

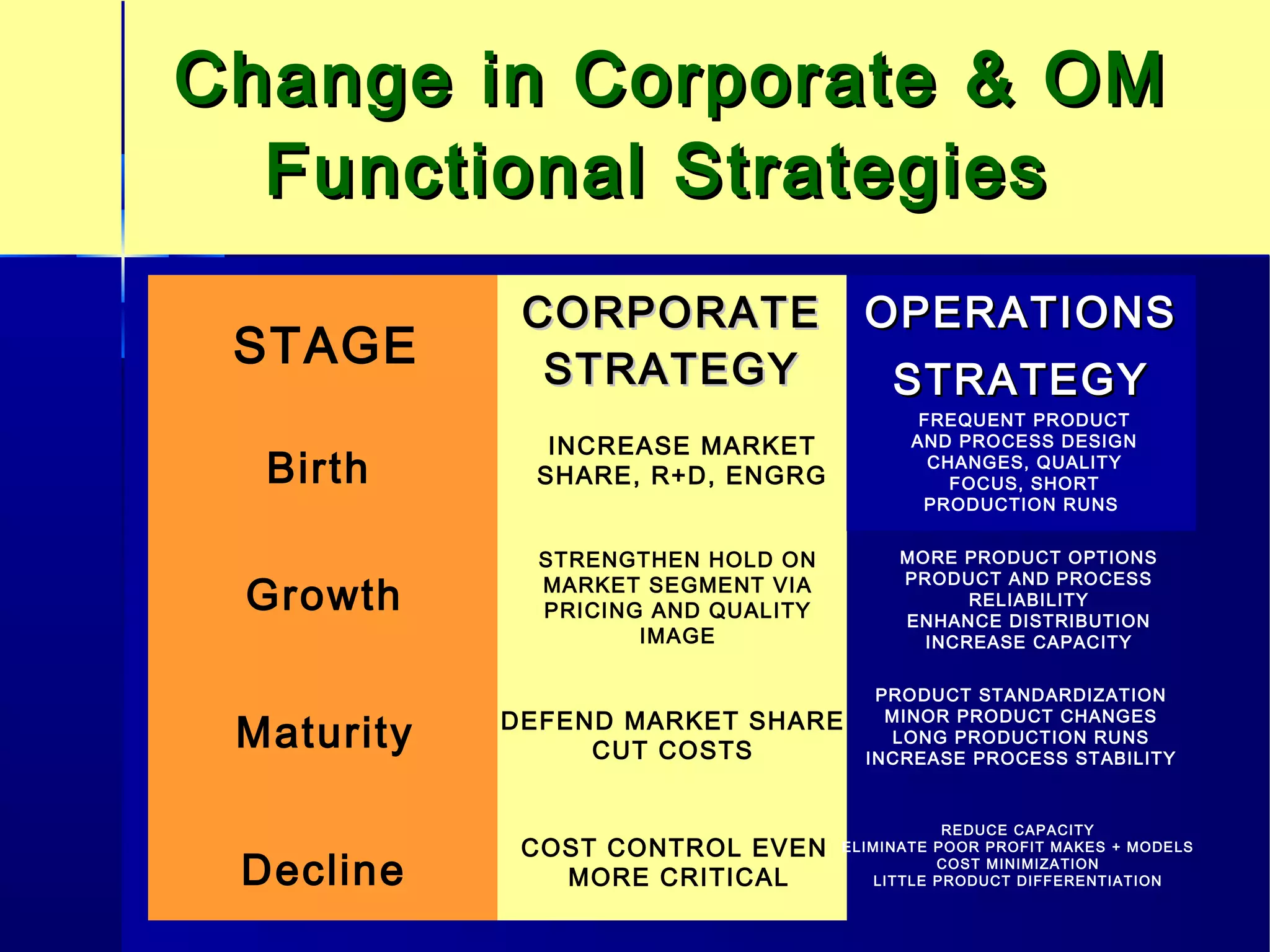

The document discusses operations management (OM), emphasizing its critical role in various sectors and its integration with marketing and finance to create competitive advantages. It outlines key concepts such as the importance of quality management, supply chain management, and the impact of technology on production processes, while also detailing skills required for OM professionals and various career opportunities in the field. Additionally, it presents ten critical decisions in OM that guide strategic planning and operational efficiency.