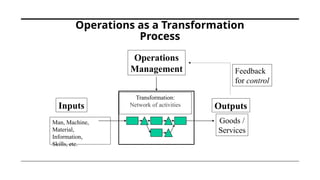

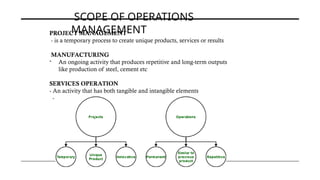

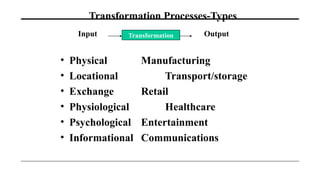

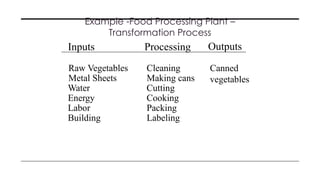

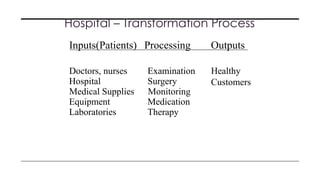

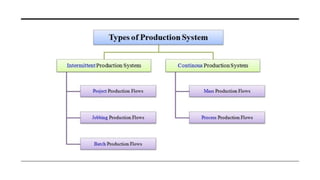

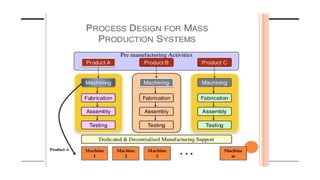

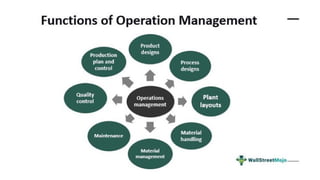

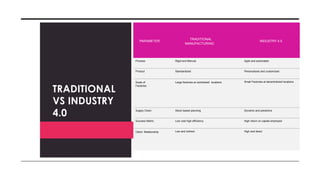

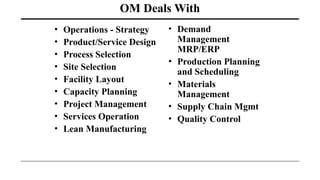

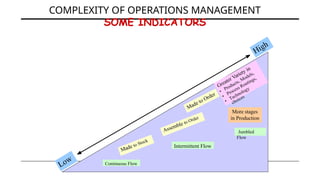

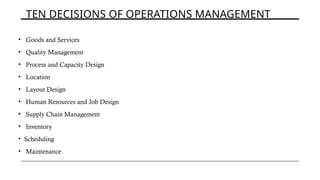

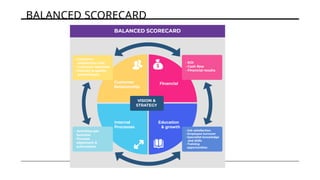

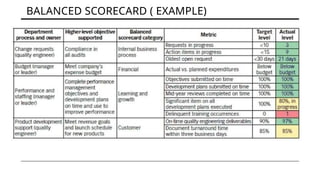

The document covers the fundamentals and importance of operations management, highlighting its role in transforming inputs to outputs while maintaining competitiveness in quality, cost, and service. It discusses various interfaces between operations management and other business functions such as marketing, human resources, finance, and IT, as well as the emerging challenges and strategic objectives within the field. Additionally, it contrasts traditional manufacturing methods with Industry 4.0 practices and presents the balanced scorecard as a tool for measuring business performance.