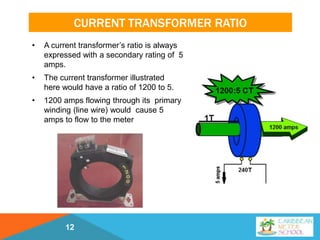

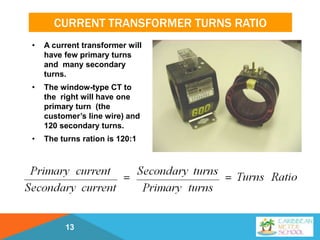

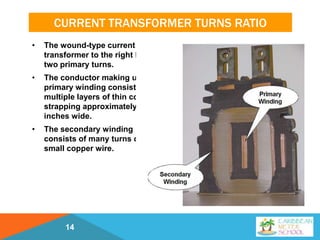

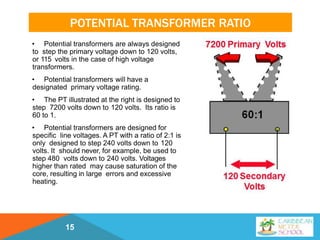

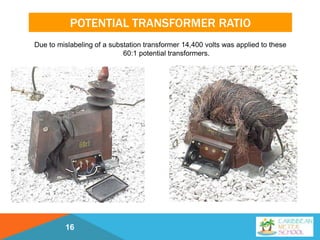

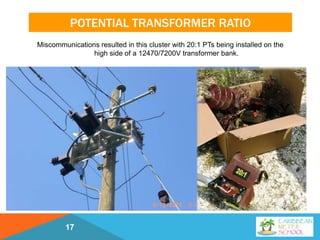

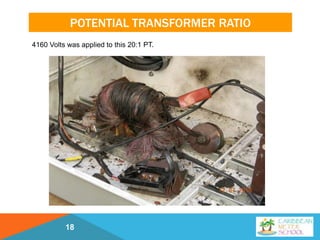

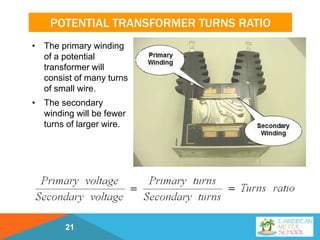

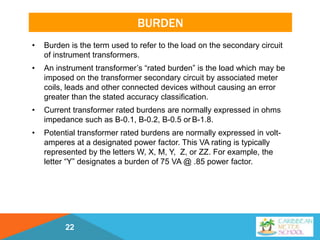

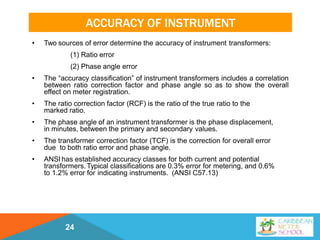

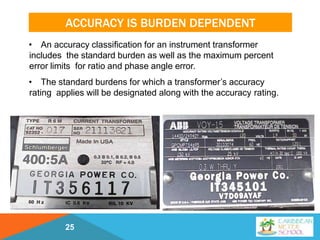

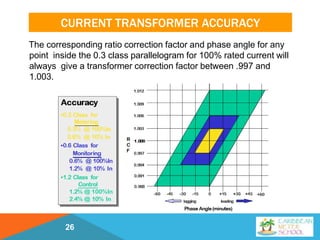

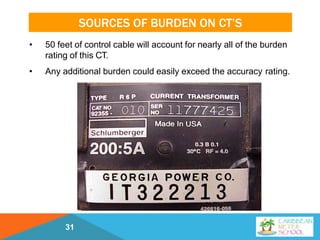

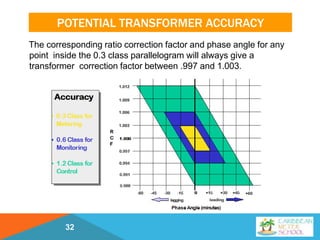

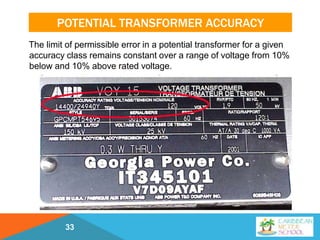

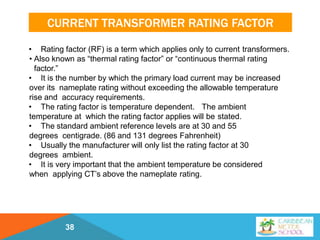

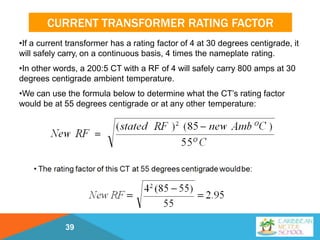

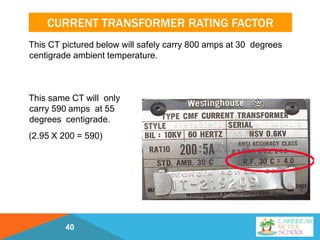

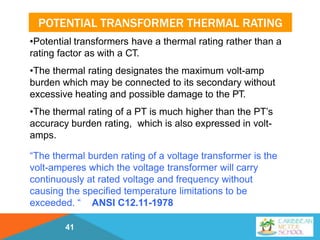

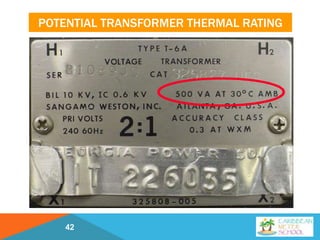

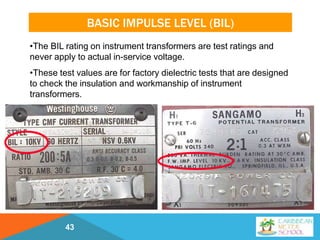

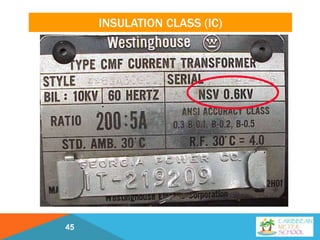

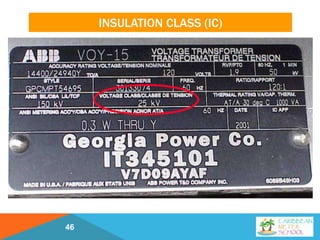

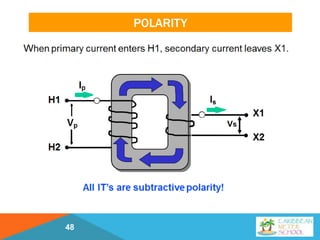

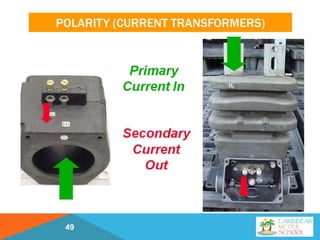

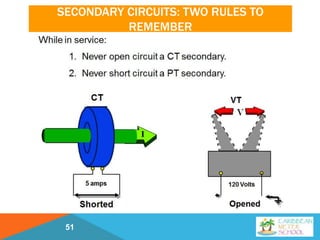

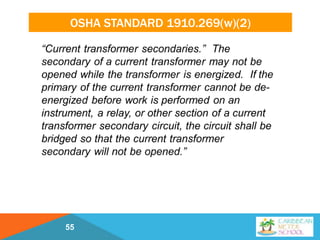

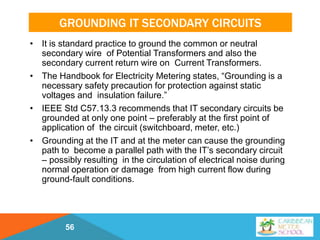

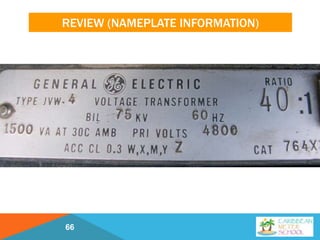

The document provides a comprehensive overview of instrument transformers, including definitions, types, ratios, accuracy, burden, and safety practices. It details current and potential transformers, their operational principles, specifications, and standards applicable to their use in electrical systems. Critical aspects such as accuracy errors, thermal ratings, insulation classes, and grounding practices are also discussed to ensure safe and effective utilization.