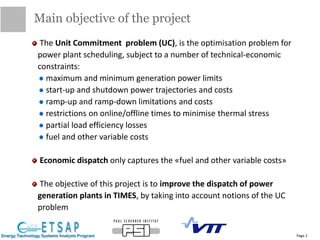

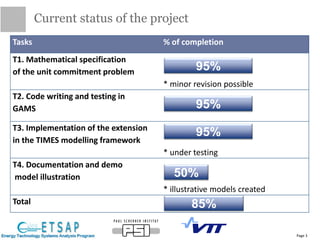

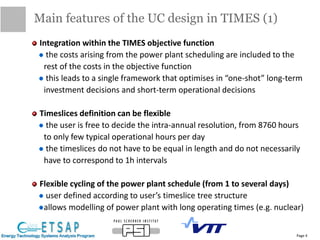

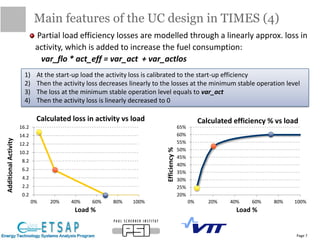

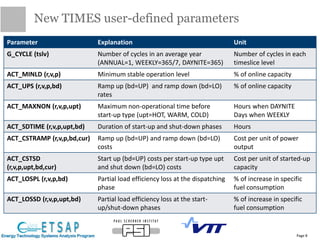

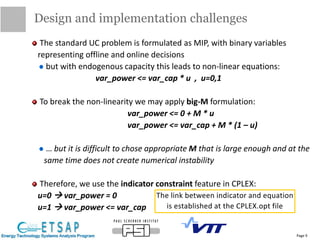

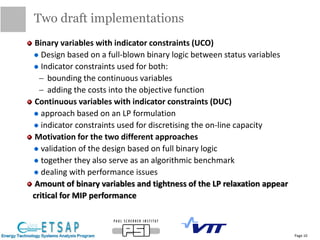

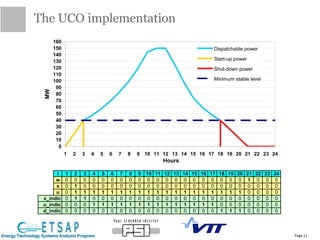

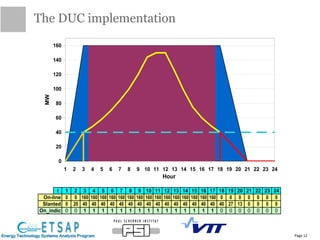

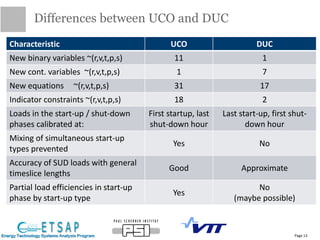

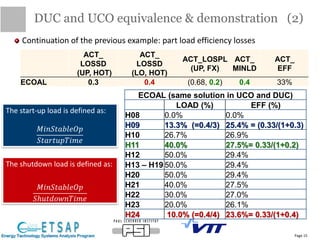

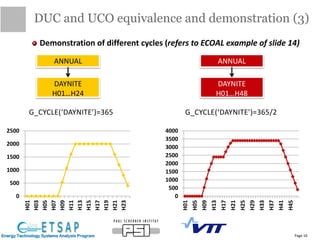

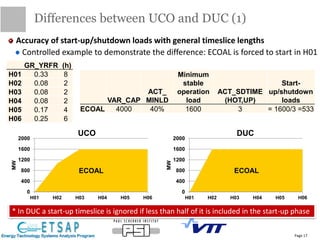

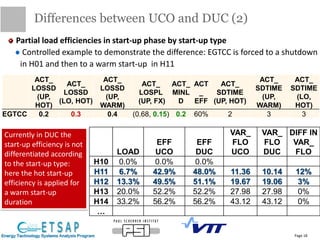

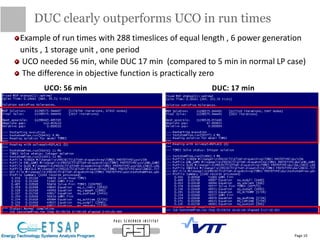

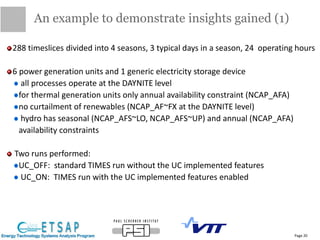

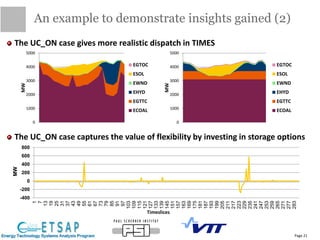

This document provides an update on the status of a project to improve the dispatch modeling of power plants in the TIMES energy systems modeling framework. It describes the implementation of a unit commitment (UC) problem into TIMES, which will allow the model to consider start-up costs and minimum run times of power plants when determining the optimal dispatch schedule. The document outlines the key features and constraints of the UC problem being modeled, provides an overview of the current implementation progress and tasks completed, and describes two different approaches - using binary variables or continuous variables - for formulating the UC problem in TIMES. Examples are also presented to demonstrate the UC modeling capabilities.