This paper introduces a new three-stage method for solving the unit commitment problem, which is a critical task in power system scheduling. The method includes generating a primal schedule, performing economic dispatch using a hybrid AI algorithm, and refining the solution through a modification process to achieve near-optimal results. Simulation results demonstrate that this approach provides robust solutions effectively within a feasible time frame.

![A new three-stage method for solving unit commitment problem

S. Khanmohammadi, M. Amiri*, M. Tarafdar Haque

Faculty of Electrical & Computer Engineering, University of Tabriz, P.O. Box 51665-343, Tabriz, Iran

a r t i c l e i n f o

Article history:

Received 25 November 2009

Received in revised form

28 March 2010

Accepted 30 March 2010

Available online 5 May 2010

Keywords:

Three-Stage method

Unit Commitment

Solution Modification Process

Economic Dispatch

a b s t r a c t

This paper presents a new Three-Stage (THS) approach for solving Unit Commitment (UC) problem. The

proposed method has a simple procedure to get at favorite solutions in a feasible duration of time by

producing a primal schedule of status of units at the first step. In the second step the operating units take

hourly values by doing Economic Dispatch (ED) on them via a hybrid serial algorithm of Artificial

Intelligence (AI) including Particle Swarm Optimization (PSO) and NeldereMead (NM) algorithms. In

spite of the acceptable solutions obtained by these two stages, the presented method takes another step

called the solution modification process (SMP) to reach a more suitable solution. The simulation results

over some standard cases of UC problem confirm that this method produces robust solutions and

generally gets appropriate near-optimal solutions.

2010 Elsevier Ltd. All rights reserved.

1. Introduction

Effective scheduling of available energy resources for satisfying

load demand has become an important task in modern power

systems [1]. In solving the UC problem, there are generally two

basic problems, namely, the unit commitment which is the

economic determining of on/off status of units in presence of

startup and shout-down constraints and the Economic Dispatch

(ED) which is economical allocation of continuous power amounts

to the operating units to meet the required demand. It should be

noticed that the optimal solutions to the UC problems can save

millions of dollars to the electric power companies [2].

The UC problem is categorized as a nonlinear, large-scale,

mixed-integer combinatorial optimization problem with

constraints. The exact solution to the problem can be obtained only

by complete enumeration, often at the cost of a prohibitively large

computation time requirement for realistic power systems [3].

Therefore the researches around the UC have been focused on

near-optimal solutions. Many methods have been proposed for

solving UC during recent decades. Exhaustive Enumeration (EE)

[4], Priority List (PL) [5e7], Dynamic Programming (DP) [8,9] and

Lagrangian Relaxation (LR) [10e12] are some of classical methods

applied to UC problems. These classical methods have their own

difficulties such as uncertainty of convergence in presence of units

with similar specifications, solutions with relatively high

operation cost, danger of a deficiency of storage capacity and their

enormously increasing calculation time for a large-scale UC

problem [1]. Aside from the mentioned methods, some intelligent

techniques are also applied to UC problems. Specially, they are

Genetic Algorithm (GA) [13], Simulated Annealing (SA) [14], Tabu

Search (TS) [15], Particle Swarm Optimization (PSO) [16], Ant

Colony Optimization (ACO) [1] and various algorithms of evolu-

tionary computation.

In this paper we focus on a new three-stage (THS) method to

solve UC problem. The proposed method has a simple procedure to

get at near-optimal solutions in a feasible duration of time by

producing a primal schedule of status of units at the first step. In the

second step the operating units take hourly values by doing

Economic Dispatch (ED) on them via a hybrid serial algorithm of

Artificial Intelligence (AI) including Particle Swarm Optimization

(PSO) [17] and NeldereMead (NM) [18] algorithms. In spite of the

acceptable solutions obtained by these two stages, the presented

method takes another step called the solution modification process

(SMP) to reach to a more suitable solution. The THS method has

been applied to some widely used UC problems with various

complexities. The simulation results confirm that this method

produces robust solutions and generally gets appropriate near-

optimal solutions.

This paper is organized as follows: Section 2 formulates the UC

problem. Section 3 describes the proposed method in detail. Each

stage of THS method has been explained in this section. Section 4

contains the simulation results and compares various UC

methods. Finally concluding remarks are discussed as well in

Section 5.

* Corresponding author. Tel.: þ98 241 4241898, þ98 9192793624 (mobile); fax:

þ98 241 4241752.

E-mail address: mohsen.amiri313@gmail.com (M. Amiri).

Contents lists available at ScienceDirect

Energy

journal homepage: www.elsevier.com/locate/energy

0360-5442/$ e see front matter 2010 Elsevier Ltd. All rights reserved.

doi:10.1016/j.energy.2010.03.049

Energy 35 (2010) 3072e3080](https://image.slidesharecdn.com/khanmohammadi2010-240826081243-5485cd55/75/A-newthree-stagemethodforsolvingunitcommitmentproblem-1-2048.jpg)

![2. Problem formulation

The objective of the UC problem is the minimization of the total

production costs over the scheduling horizon [16]. The cost func-

tion including fuel and startup costs of N units in an hour is pre-

sented by Eq. (1).

CostN ¼

X

N

i ¼ 1

h

FCiðPihÞ þ STCi

1 Uiðh1Þ

i

Uih: (1)

FC is usually a quadratic polynomial with coefficients gi, bi and ai

like Eq. (2) and STC is defined by Eq. (3).

FCiðPihÞ ¼ giP2

ih þ biPih þ ai (2)

STCi ¼

(

HscX

off

i

MDi þ Cs hrs

CscX

off

i

MDi þ Cs hrs

(3)

The startup cost for a unit depends on its downtime. If it is longer

than the related MD plus its predefined Cold-Start hours (Cs_hrs),

Cold-Start cost (Csc) is needed to operate it. Else if the ith unit

downtime is shorter than the mentioned duration, Hot-Start cost

(Hsc) is needed to operate it.

The total cost is determined by summation of Eq. (1) in all hours

of scheduling horizon as Eq. (4).

CostNH ¼

X

H

h ¼ 1

X

N

i ¼ 1

h

FCiðPihÞ þ STCi

1 Uiðh1Þ

i

Uih: (4)

During minimization process, some essential constraints must

be satisfied. The main and prevalent constraints of UC problem are

as below:

1) Power balance constraint

X

N

i ¼ 1

PihUih ¼ Dh (5)

2) Spinning reserve constraint

X

N

i ¼ 1

PiðmaxÞUih Dh þ Rh (6)

3) Generation limit constraints

PiðminÞ Pih PiðmaxÞ (7)

4) Minimum downtime constraint

Xoff

i ðtÞ MDi (8)

5) Minimum up-time constraint

Xon

i ðtÞ MUi (9)

6) Initial status constraint

This means that the initial status of units must be considered in

the first hour of scheduling.

3. Proposed method

This paper presents a Three-Stage (THS) method to reach the

final solution of the UC problem. In the first stage some logical

instructions are used to produce the primal status of all unit status

in all scheduling time horizon in a matrix. It is necessary that all

committed units take some feasible and economical values (ED) in

the second stage. ED procedure in this paper follows a hybrid

artificial intelligence algorithm. PSO in series with NM when

operates on ED continues variable problem iteratively, is able to

yield an effective solution.

As it will be shown in part of simulation results, the output of

two recent stages may be considered as a suitable and near-optimal

solution in most of the time. But the final stage is still remains. The

Nomenclature

CostNH total costs of N generators in H hours;

FCi(Pih) fuel cost of ith unit with output Pih at the hth hour;

STCi Startup cost of ith unit;

Uih on/off status of ith unit; Uih ¼ 0 and Uih ¼ 1 are for

off and on statuses respectively.

N number of generators;

H number of hours;

Dh load demand at the hth hours;

Rh spinning reserve at the hth hours; spinning reserve

is the surplus power of total generation capacity

after meeting load demand at the hth hour (usually

10% of load demand)

Pi(min) minimum generation limit of the ith unit;

Pi(max) maximum generation limit of the ith unit;

MUi minimum up-time of the ith unit;

MDi minimum downtime of the ith unit;

Xi

on

duration that the ith unit is continuously on;

Xi

off

duration that the ith unit is continuously off;

(1)

Primal configuration of all

units

(A matrix with 0/1 elements for

On/Off statuses)

(3)

Solution Modification Process

(Replacing some On and Off

Statuses in each hour and

doing ED on new arrangement)

(2)

Economic Dispatch

(All nonzero statuses

take continues values)

Fig. 1. Stages of proposed method.

D (MW)

Time (h)

Variant Portion

Constant Portion

Fig. 2. A typical load demand plot. It has been divided in to constant and variant

portions.

S. Khanmohammadi et al. / Energy 35 (2010) 3072e3080 3073](https://image.slidesharecdn.com/khanmohammadi2010-240826081243-5485cd55/85/A-newthree-stagemethodforsolvingunitcommitmentproblem-2-320.jpg)

![i. Because of the non-perfect successful rate of AI algorithms in

finding the optimal solution, it is recommended to repeat the

algorithm at most six times. However after four runs that

improvement occurs, the repetition can be stopped.

ii. Merging a calculated solution by random initial population of

algorithm may accelerate the convergence of the algorithm.

As we know because of common small amounts of spinning

reserve (5e10%), it is predictable that all of the committed

units have to work in near around their full capacitance.

Knowing this point, Fig. 6 describes more about how to create

such solutions in a 10 unit system.

iii. The bad convergence of solutions must be checked between

PSO and NM to prevent useless extra cost evaluations. This

causes to save considerable amount of time.

iv. Whereas the dimension of ED problems changes by number

of committed units in each hour, they have not the same

complexity. To save much more execution time, we can use

different population size in each hour. The recommended

population size for PSO is usually a constant value between 20

and 50. But in this paper an hourly changing population size is

used as follows:

Npopulation;h ¼ a þ 3ðn:c:uÞh (11)

When Npopulation,h is the population size in hth hour, a ˛

{20,21,.40}, 3 ˛ {1,2} and (n.c.u)h is the number of committed units

in hth hour.

3.3. Stage three: Solution Modification Process (SMP)

The solution produced by two stages is near optimal, but this part

introduces a modificationprocess that yields a more precise solution

by acting on the produced solution. Considering constraints (8) and

(9), any replacement in solution elements may cause in its dis-

assembling. The proposed SMP devises a plan to decrease the cost by

saving the total shape of solution while satisfying two mentioned

constraints. In brief, just those units that do not take any affect in the

other hours are allowed to be changed their status.

The procedure is as follows:

i. Determine all units in each hour which are allowed to be

turned off as the first group (FG).

ii. Then in the same hour, determine the second group (SG) with

units that are allowed to be committed instead of the units

belong to FG.

iii. In this step, it is needed to replace the units belonging to the

FG with the units belonging to the SG one by one. After doing

ED on the new arrangement, if the operating cost of this hour

has been decreased, it will be preferred to the primary

arrangement. Some units are prior to the others in both

groups to commence the replacements. Those units which

have more expensive operating constant cost (a) are prior to

the other units in the FG. The priority list of units which

belong to SG is defined as Eq. (12). The units with lower

amounts are prior to the others.

Priority List ¼ Diffrence of STCis in new and old status of units

þ avec

(12)

Fig. 7; describes the SMP in more detail.

Considering second note on stage two, the recent ED solution of

each hour can be merged by the random initial population instead

of those were showed in Fig. 6. This solution accelerates the

searching process of ED in the third stage. Fig. 8; depicts how the

SMP acts on output of two latest stages. Five modifications have

been done on primary configuration. Rectangular and oval boxes

present the units of FG and SG respectively. The other on/off units in

the same hours are those which are not allowable to be changed.

4. Simulation results

In this section we are going to test the efficiency of the proposed

method by solving some standard UC problems. These standard

problems contain four unit systems, two versions of ten unit system

and twenty unit systems. The last column of data tables of units in

each system contains the information of initial status of units. The

Table 3

Simulation results of 4 unit system. B.SMP and A.SMP are the amounts for before and

after SMP respectively. Sign (e) means that no amount has been reported.

Method Best ($) Average ($) Worst ($)

LR [19] 75232 e e

PSOeLR [19] 74808 e e

Proposed B. SMP 74812 74877 75166

A. SMP 74812 74877 75166

Table 4

Load demand data of 10 unit system.

Hour 1 2 3 4 5 6 7 8 9 10 11 12

Load (MW) 700 750 850 950 1000 1100 1150 1200 1300 1400 1450 1500

Hour 13 14 15 16 17 18 19 20 21 22 23 24

Load (MW) 1400 1300 1200 1050 1000 1100 1200 1400 1300 1100 900 900

Table 5

Units information of 10 unit system.

Unit P(max) P(min) a b g MD MU Hsc Csc Cs hrs Initial status

(MW) (MW) ($/h) ($/MWh) ($/MW2

h) (h) (h) ($) ($) (h) (h)

1 455 150 1000 16.19 0.00048 8 8 4500 9000 5 8

2 455 150 970 17.26 0.00031 8 8 5000 10000 5 8

3 130 20 700 16.60 0.002 5 5 550 1100 4 5

4 130 20 680 16.50 0.00211 5 5 560 1120 4 5

5 162 25 450 19.70 0.00398 6 6 900 1800 4 6

6 80 20 370 22.26 0.00712 3 3 170 340 2 3

7 85 25 480 27.74 0.0079 3 3 260 520 2 3

8 55 10 660 25.92 0.00413 1 1 30 60 0 1

9 55 10 665 27.27 0.00222 1 1 30 60 0 1

10 55 10 670 27.92 0.00173 1 1 30 60 0 1

S. Khanmohammadi et al. / Energy 35 (2010) 3072e3080 3077](https://image.slidesharecdn.com/khanmohammadi2010-240826081243-5485cd55/85/A-newthree-stagemethodforsolvingunitcommitmentproblem-6-320.jpg)

![negative and positive amounts show the hours the units were off

and on respectively before the first hour. Results of the proposed

method have two parts: Simulation results before SMP and after

SMP. This gives a better comparison of SMP abilities. Also three

different fonts have been used in tables of simulation results: the

lowest cost in each column is shown in Bold. The other reported

methods which present a more expensive cost in respect of

proposed method have been shown in italic. The rest amounts have

been shown by ordinary font. The best, average and the worst

amounts have been yielded after several executions of presented

methods. In this paper 10 runs have been executed for proposed

method.

Case 1: This system contains four power generating units. Load

demand data is shown in Table 1. As it is clear, the time horizon of

this problem is 8 h. Table 2, presents the data of this four unit

system. As it can be seen in Table 3, the proposed method is the best

method after the PSOeLR [19] with just four dollars difference.

Another important index of a good solution is robustness of the

method over several executions. The methods that yield similar

solutions in various executions are more reliable than the other

methods. The low average amount of THS confirms its robustness.

Case 2: A system with ten generating units has been selected to

study in this part. Table 4 contains the information of load demand

in 24 h. This system has two very usual UC problems. Ten unit

system with 5% spinning reserve and ten unit system with 10%

spinning reserve. Here we are going to solve this system with 5% of

spinning reserve and the next one will be considered in the third

case. Table 5 yields more information of these ten units.

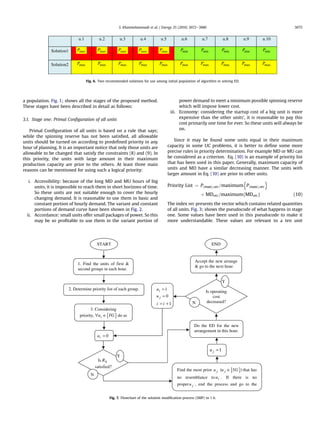

Remarkable results of proposed method are seen in Table 6. THS

presents the lowest costs in all three Best, Average and Worst

columns. Also as mentioned above, the low average amount

emphasizes on robustness of THS method. Arrangement of units in

all 24 h of a day after SMP is shown in Fig. 9. Fuel cost, startup cost

and modification rate after SMP are presented respectively in three

right columns.

Case 3: The same units mentioned in case 2 but with 10%

spinning reserve. Table 7 compares the reported methods. THS

surpasses other methods in Best and Worst amounts. The average

amounts show that THS has the third rank after AG [30] and

CReGA [31].

Case 4: By duplicating the amounts of Case 2, it is possible to

define a new UC problem with 20 units. This problem has been

known as a standard UC problem. Presence of many similar units

in a UC problem may challenge the methods in choosing one

situation among many possible situations. These kinds of problem

may have some optimum solutions with equal costs. Table 8,

contains results of proposed method and some other method. In

column of Best costs just EALR [12] has lower cost than proposed

method. However most of the average and worst amounts has not

been reported, but the proposed method includes the enough

efficiency to yield suitable costs with respect to most of the other

methods.

Table 6

Simulation results of 10 unit system with 5% of spinning reserve. B.SMP and A.SMP

are the amounts for before and after SMP respectively. Sign (e) means that no

amount has been reported.

Method Best ($) Average ($) Worst ($)

BPSO [20] 565,804 566,992 567,251

GA [20] 570,781 574,280 576,791

APSO [21] 561,586 e e

BP [21] 565,450 e e

TSGB [22] 560,263.9151 e e

IPSO [23] 558,114.8 e e

Hybrid PSOeSQP

[24]

568,032.3 e e

Proposed B.SMP 558,844.7568 558,937.2371 559,154.9755

A.SMP 557,676.8104 557,769.2891 557,987.0291

Modification Rate

($)

Start up cost

($)

Fuel Cost

($)

10

9

8

7

6

5

4

3

2

1

Unit

0

0

13684

0

0

0

0

0

0

0

0

245

455

H01

0

0

14554

0

0

0

0

0

0

0

0

295

455

H02

0

0

16302

0

0

0

0

0

0

0

0

395

455

H03

0

900

18598

0

0

0

0

0

40

0

0

455

455

H04

0

0

19609

0

0

0

0

0

90

0

0

455

455

H05

31.1440

560

21860

0

0

0

0

0

60

130

0

455

455

H06

0

1100

23262

0

0

0

0

0

25

130

130

410

455

H07

0

0

24150

0

0

0

0

0

30

130

130

455

455

H08

253.1673

340

26589

0

0

0

0

20

110

130

130

455

455

H09

0

520

29336

0

0

0

25

43

162

130

130

455

455

H10

0

60

31220

0

0

13

25

80

162

130

130

455

455

H11

0

60

33205

0

10

53

25

80

162

130

130

455

455

H12

0

0

29336

0

0

0

25

43

162

130

130

455

455

H13

253.1673

0

26589

0

0

0

0

20

110

130

130

455

455

H14

0

0

24150

0

0

0

0

0

30

130

130

455

455

H15

0

0

21514

0

0

0

0

0

25

130

130

310

455

H16

0

0

20642

0

0

0

0

0

25

130

130

260

455

H17

0

0

22387

0

0

0

0

0

25

130

130

360

455

H18

0

0

24150

0

0

0

0

0

30

130

130

455

455

H19

0

600

29336

0

0

0

25

43

162

130

130

455

455

H20

31.1410

0

27267

0

0

0

25

73

162

130

0

455

455

H21

0

0

22735

0

0

0

25

20

145

0

0

455

455

H22

39.3298

0

17645

0

0

0

0

20

0

0

0

425

455

H23

0

0

15427

0

0

0

0

0

0

0

0

345

455

H24

4140

553540

Total Cost ($)= 557677

Fig. 9. Solution of 10 generating unit with 5% of spinning reserve, presented by proposed method. Some amounts may have round off error.

S. Khanmohammadi et al. / Energy 35 (2010) 3072e3080

3078](https://image.slidesharecdn.com/khanmohammadi2010-240826081243-5485cd55/85/A-newthree-stagemethodforsolvingunitcommitmentproblem-7-320.jpg)

![5. Conclusion

In this paper by presentation of a new three-stage method

(THS), some of widely used and standard problems of UC were

solved and were compared with several other methods. The

proposed method gains from some logical and simple steps

combined with an intelligent algorithm. THS produces primal on/

off status of the all units during all planning horizon. Then does ED

and finally via a novel solution modification process (SMP) modifies

the initially produced schedule and yields a schedule with

comparable total cost including fuel and startup costs. Simulation

results confirm that THS is more economical than many other

methods and its solutions are considerably robust and reliable over

several executions.

Applying the THS to the large-scale UC problems and also doing

some supplementary improvements on its procedure can be the

subject of future researches.

Acknowledgment

The authors would like to thank their dear friend Ehsan Bathaei

from the Royal Melbourne Institute of Technology (RMIT) for the

revision of this paper.

References

[1] Saber AY. Scalable unit commitment by memory bounded ant colony opti-

mization with A* local search. Electrical Power Energy Systems 2008;30

(6e7):403e14.

[2] Hossein SH, Khodaei A, Aminifar F. A novel straightforward unit commitment

method for large-scale power systems. IEEE Transactions on Power Systems

2007;22(4):2134e43.

[3] Wood AJ, Wollenberg FB. Power generation operation and control. 2nd ed.

New York: Wiley-Interscience; 1996.

[4] Kerr RH, Scheidt JL, Fontana AJ, Wiley JK. Unit commitment. IEEE Transactions

on Power Apparatus and Systems 1966;85(5):417e21.

[5] Bums RM, Gibson CA. Optimization of priority lists for a unit commitment

program. In: Proceedings of the IEEE power engineering society summer

meeting; 1975.

[6] Lee FN. Short-term thermal unit commitment- a new method. IEEE Trans-

actions on Power Systems 1998;3(2):421e8.

[7] Senjyu T, Shimabukuro K, Uezato K, Funabashi T. A fast technique for unit

commitment problem by extended priority list. IEEE Transactions on Power

Systems 2003;18(2):882e8.

[8] Lowery PG. Generating unit commitment by dynamic programming. IEEE

Transactions on Power Apparatus and Systems 1996;85(5):422e6.

[9] Happ HH, Johnson RC, Wright WJ. Large scale hydro-thermal unit commit-

ment-method and results. IEEE Transactions on Power Apparatus and Systems

1971;90(3):1373e84.

[10] Merlin A, Sandrin P. A method for unit commitment at Electricite de France.

IEEE Transactions on Power Apparatus and Systems 1983;102(5):1218e25.

[11] Aoki K, Itoh M, Satoh T, Nara K, Kanezashi M. Optimal long-term Unit

Commitment in large scale systems including fuel constrained thermal and

pumped-storage hydro. IEEE Transactions on Power Systems 1989;4

(3):1065e73.

[12] Ongsakul W, Petcharaks N. Unit Commitment by enhanced adaptive

Lagrangian relaxation. IEEE Transactions ion Power Systems 2004;19

(1):620e8.

[13] Kazarlis SA, Bakirtzis AG, Petridis V. A genetic algorithm solution to the unit

commitment problem. IEEE Transactions on Power Systems 1996;11

(1):83e92.

[14] Mantawy AH, Abdel-Magid YL, Selim SZ. A simulated annealing algorithm for

unit commitment. IEEE Transactions on Power Systems 1998;13(1):197e204.

[15] Mori H, Matsuzaki O. Application of priority-list-embeded tabu search to unit

commitment in power systems. Transactions of the Institute of Electrical

Engineers of Japan 2001;121-B(4):535e41.

[16] Ting TO, Rao MVC, Loo CK. A novel approach for unit commitment problem via

an effective hybrid particl sowarm optimization. IEEE Transactions on Power

Systems 2006;21(1):411e8.

[17] Kennedy J, Eberhart RC. Particle swarm optimization. In: Proceedings of IEEE

international conference on neural network, vol. 2. Piscataway, NJ: IEEE

Service Center; 1995. p. 1942e8.

[18] Lagarias JC, Reeds JA, Wright MH, Wright PE. Convergence properties of the

Nelder Mead simplex method in low dimensions. Journal of the Society for

Industrial and Applied Mathematics 1998;9(1):112e47.

[19] Sriyanyong P, Song YH. Unit commitment using particle swarm optimization

combined with Lagrange relaxation. In: Power Engineering Society general

meeting, vol. 3; 2005. p. 2752e9.

[20] Gaing ZL. Discrete particle swarm optimization algorithm for unit commit-

ment. In: IEEE Power Engineering Society general meeting, vol. 1; 2003. p.

13e7.

[21] Pappala VS, Erlich I. A new approach for solving the unit commitment

problem by adaptive particle swarm optimization, Power and Energy Society

general meeting-conversion and delivery of electrical energy in the 21st

century. USA: IEEE; 2008. p. 1e6.

[22] Eldin AS, El-sayed MAH, Youssef HKM. A two-stage genetic based technique

for the unit commitment optimization problem. In: 12th International Middle

East Power System Conference, MEPCO, Aswan; 2008. p. 425e30.

[23] Xiong W, Li MJ, Cheng YL. An improved particle swarm optimization algo-

rithm for unit commitment. In: Proceedings of the 2008 international

conference on intelligent computation technology and automation, vol. 01;

2008. p. 21e5.

[24] Victoire TAA, Jeyakumar AE. Hybrid PSOSQP for economic dispatch with

valve-point effect. Electric Power Systems Research 2004;71(1):51e9.

[25] Juste KA, Kita H, Tunaka E, Hasegawa J. An evolutionary programming solution

to the unit commitment problem. IEEE Transactions on Power Systems

1999;14(4):1452e9.

[26] Senjyu T, Yamashiro H, Uezato K, Funabashi T. A unit commitment problem by

using genetic algorithm based on unit characteristic classification. In:

Proceedings of the IEEE Power Engineering Society winter meeting, vol. 1;

2002. p. 58e63.

[27] Cheng CP, Liu CW, Liu CC. Unit commitment by Lagrangian relaxation and

genetic algorithms. IEEE Transactions on Power Systems 2000;15

(2):707e14.

[28] Chusanapiputt S, Nualhong D, Jantarang S, Phoomvuthisarn S. A Solution to

unit commitment problem using hybrid ant system/priority list method. In:

IEEE 2nd international conference on power and energy, PECon 08, Malaysia;

2008. p. 1183e8.

Table 7

Simulation results of 10 unit system with 10% of spinning reserve. B.SMP and A.SMP

are the amounts for before and after SMP respectively. Sign (e) means that no

amount has been reported.

Method Best ($) Average ($) Worst ($)

EP [25] e 565,352 e

GA [13] 565,852 e 570,032

UCCeGA [26] 563,977 e 565,606

DP [13] 565,825 e e

LR [13] 565,825 e e

LRGA [27] 564,800 e e

HPSO [16] 563,942.3 564,772.3 565,782.3

HASP [28] 564,029 564,324 564,490

ICGA [29] e 566,404 e

AG [30] e 564,005 e

EALR [12] 563,977 e e

CReGA [31] e 563,977 e

MPL [32] 563,977.1 e e

TSGB [22] 568,315 e e

Proposed B.SMP 564,017.73 564,121.46 564,401.08

A.SMP 563,937.26 564,040.30 64,320.61

Table 8

Simulation results of 20 unit system with 10% of spinning reserve. B.SMP and A.SMP

are the amounts for before and after SMP respectively. Sign (e) means that no

amount has been reported.

Method Best ($) Average ($) Worst ($)

ICGA [29] e 1,127,244 e

LRGA [27] e 1,122,622 e

GA [13] 1,126,243 e 1,132,059

LR [13] 1,130,660 e e

EP [25] 1,125,494 1,127,257 1,129,793

AG [30] e 1,124,651 e

BCGA [29] 1,130,291 e e

UCCeGA [26] 1,125,516 e e

DPLR [12] 1,128,098 e e

SF [2] 1,125,161 e e

EALR [12] 1,123,297 e e

CReGA [31] e 1,236,981 e

Proposed B.SMP 1,124,838 1,125,102 1,125,283

A.SMP 1124490 1,124,803 1,124,995

S. Khanmohammadi et al. / Energy 35 (2010) 3072e3080 3079](https://image.slidesharecdn.com/khanmohammadi2010-240826081243-5485cd55/85/A-newthree-stagemethodforsolvingunitcommitmentproblem-8-320.jpg)

![[29] Damousis IG, Bakirtzis AG, Dokopoulos PS. A solution to the unit commitment

problem using integer-coded genetic algorithm. IEEE Transactions on Power

Systems 2004;19(2):1165e72.

[30] Satoh T, Nara K. Maintenance scheduling by using simulated annealing

method for power plants. IEEE Transactions on Power Systems 1991;6

(2):850e7.

[31] Tokoro KI,MasudaY,Nishina H.Solvingunit commitmentproblem bycombining

of continuous relaxation method and genetic algorithm. In: SICE annual

conference. Japan: The University Electro-Communications; 2008. p. 3474e8.

[32] Tingfang Y, Ting TO. Methodological priority list for unit commitment

problem. In: International conference on computer science and software

engineering, CSSE, vol. 1; 2008. p. 176e9.

S. Khanmohammadi et al. / Energy 35 (2010) 3072e3080

3080](https://image.slidesharecdn.com/khanmohammadi2010-240826081243-5485cd55/85/A-newthree-stagemethodforsolvingunitcommitmentproblem-9-320.jpg)