1. The document provides an introduction to pattern making, discussing that patterns are templates used to cut fabric for garments.

2. Pattern making involves technical skills to interpret designs and understand garment construction, acting as a bridge between design and production.

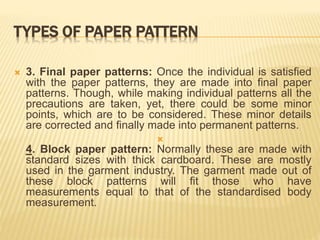

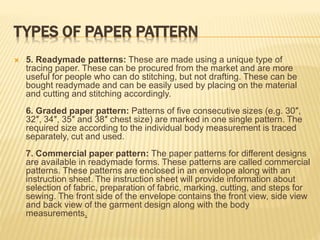

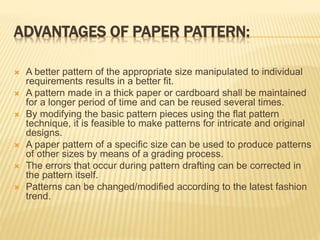

3. The document describes different types of paper patterns including standardized, individualized, final, block, readymade, graded, and commercial patterns.