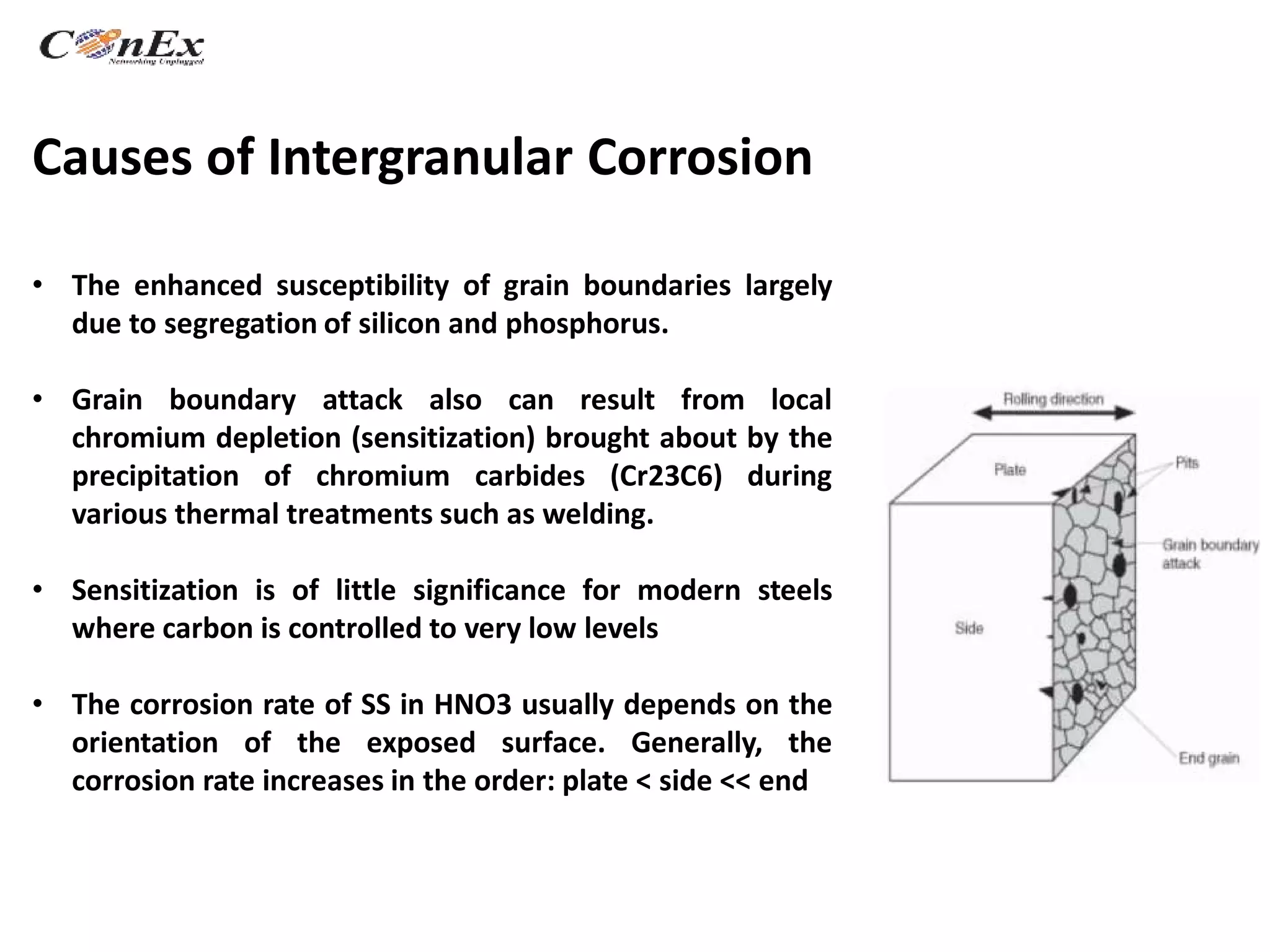

Dr. Shagufta Khan presented on understanding end grain corrosion in austenitic stainless steels. End grain corrosion occurs preferentially at grain boundaries and is caused by segregation of elements like silicon and phosphorus along the boundaries. It is a problem in nuclear reprocessing plants where stainless steel tubing is exposed to highly oxidizing nitric acid. Laser remelting and weld overlays can be used to control end grain corrosion by modifying the microstructure and masking susceptible material, while solution annealing homogenizes the material's structure.

![Dr Shagufta Khan

Present Company: AMCO Integrity Pty Ltd

Name & : Dr Shagufta Khan

Designation: Director Asset Integrity and Corrosion

Academic

Qualification: Ph.D. Corrosion engineering

Specialized Knowledge: Asset Integrity and Corrosion

Achievements: 18 Publications in international journals and conference proceedings

Guest editor for [Sustainability] Special Issue - Sustainable Materials,

Manufacturing and Design.

Key points of the Paper](https://image.slidesharecdn.com/igc-210403024906/75/Intergranular-corrosion-in-SS-tubes-2-2048.jpg)