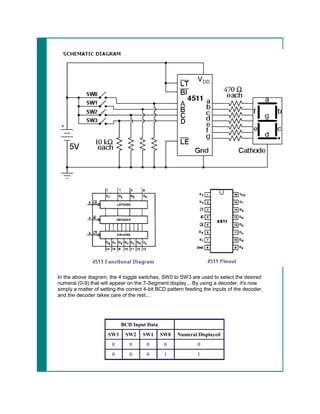

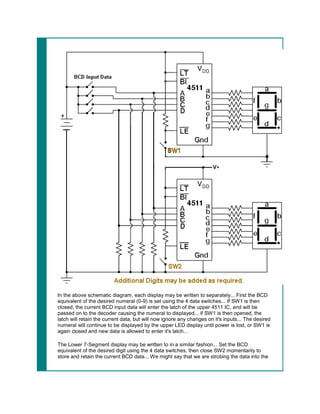

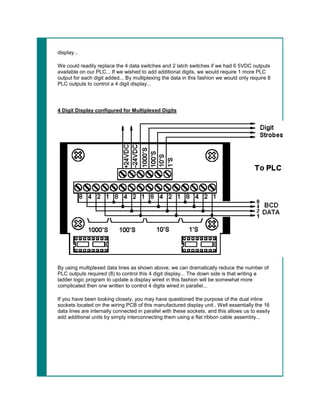

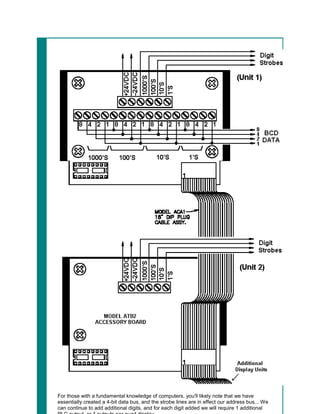

This document discusses interfacing 7-segment numeric displays to a PLC. It describes how 7-segment displays work with BCD to 7-segment decoders. It provides examples of interfacing displays in parallel and multiplexed configurations. Multiplexing allows controlling multiple displays using fewer PLC outputs by sequentially writing data to each display's latch.