This document summarizes the key details of an MWD tool manufacturer called inSIGHT. It provides:

1) Contact information and an overview of inSIGHT's state-of-the-art MWD equipment and competitive advantages including high LCM tolerance, real-time measurements, and configurable operational modes.

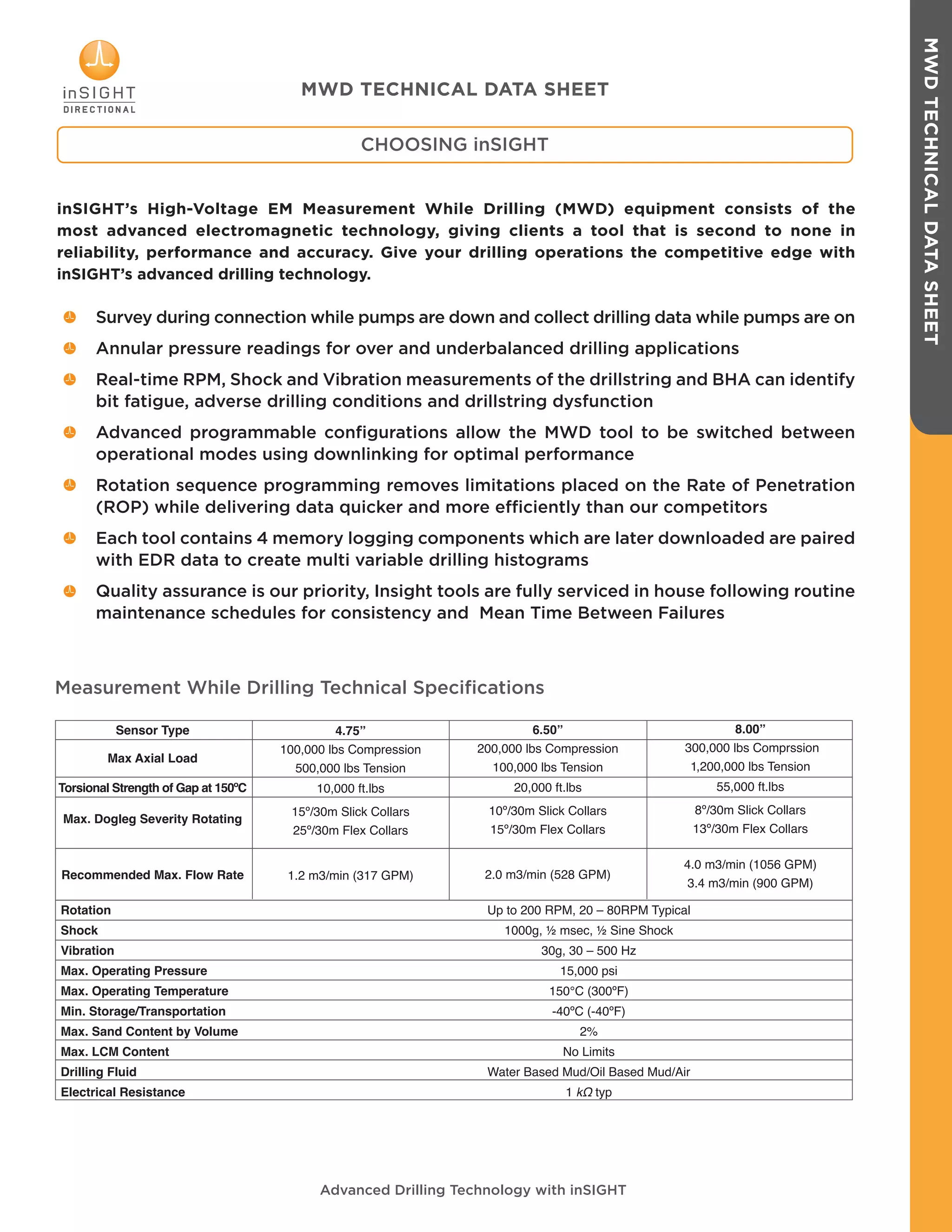

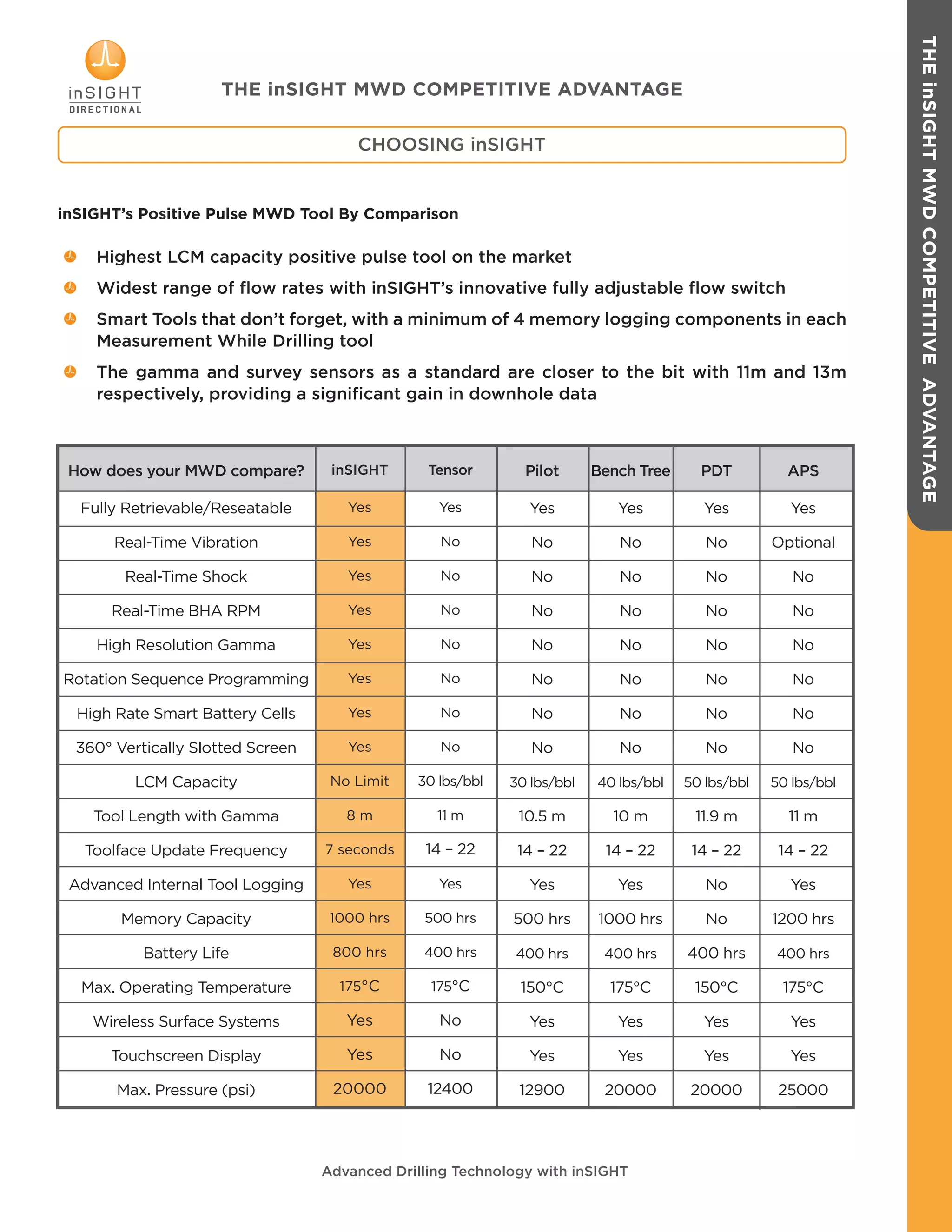

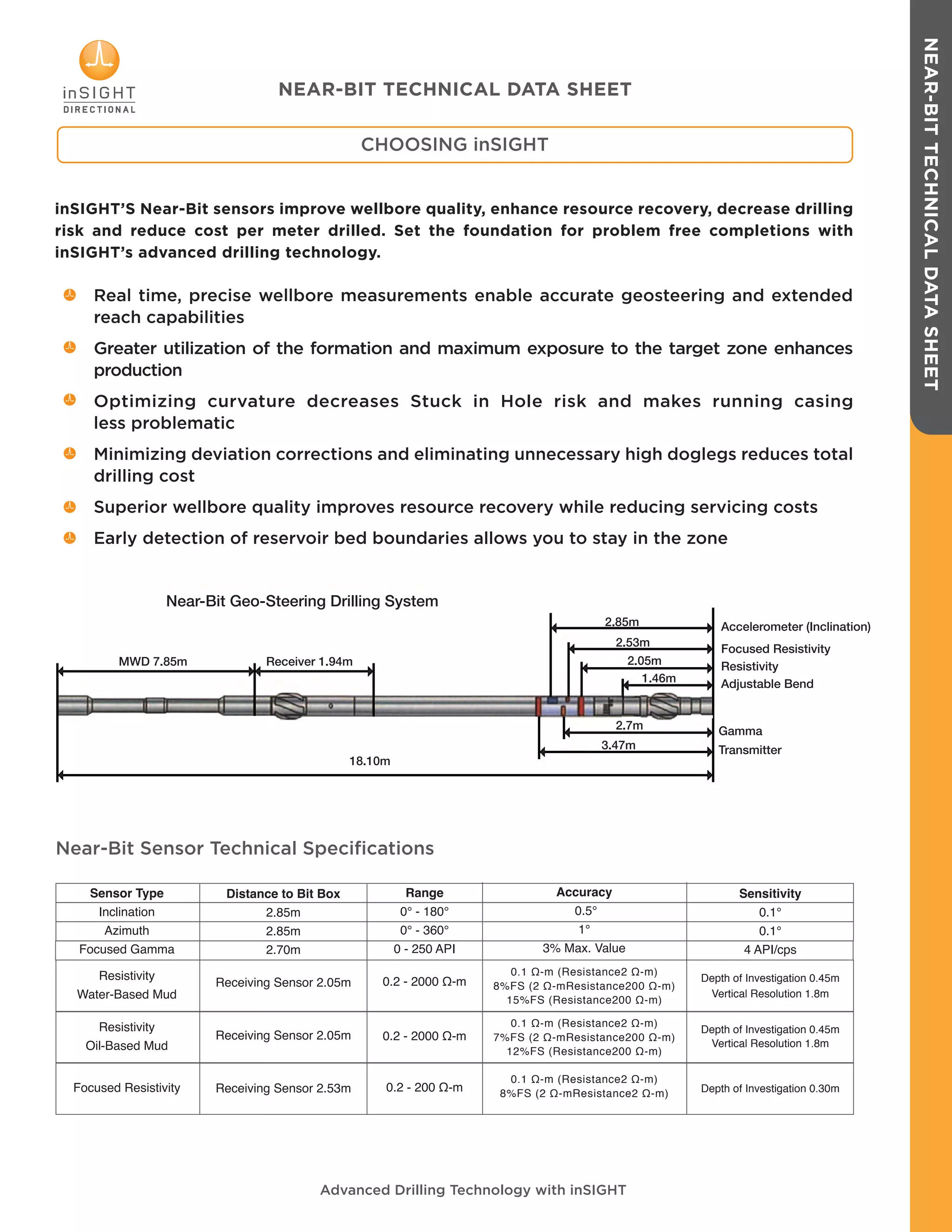

2) Technical specifications and performance details of inSIGHT's positive pulse and electromagnetic MWD tools, near-bit sensors, and competitive advantages over other MWD providers.

3) A health and safety policy statement outlining inSIGHT's commitment to preventing injuries, maintaining a safe work environment, and complying with regulations.