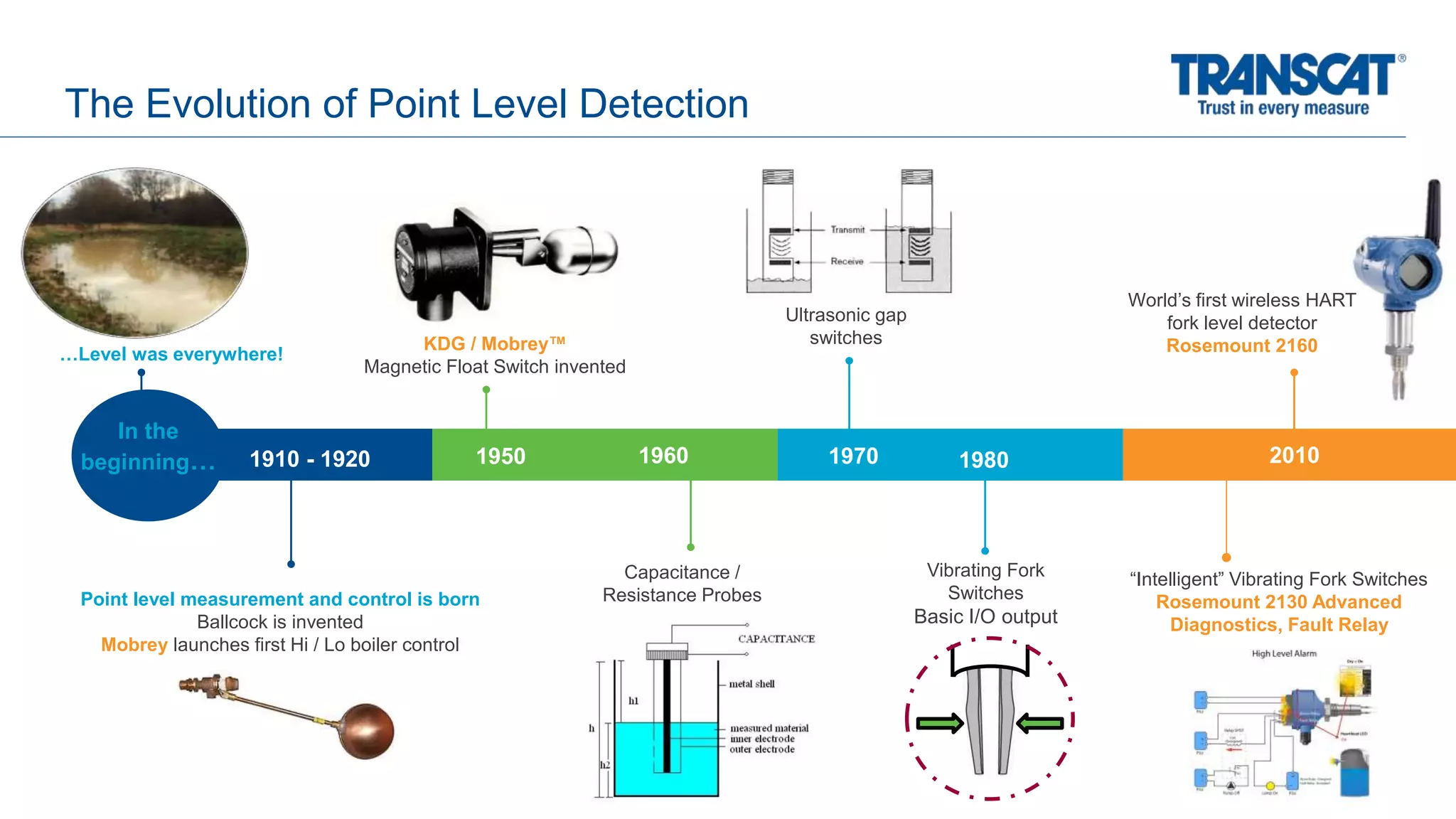

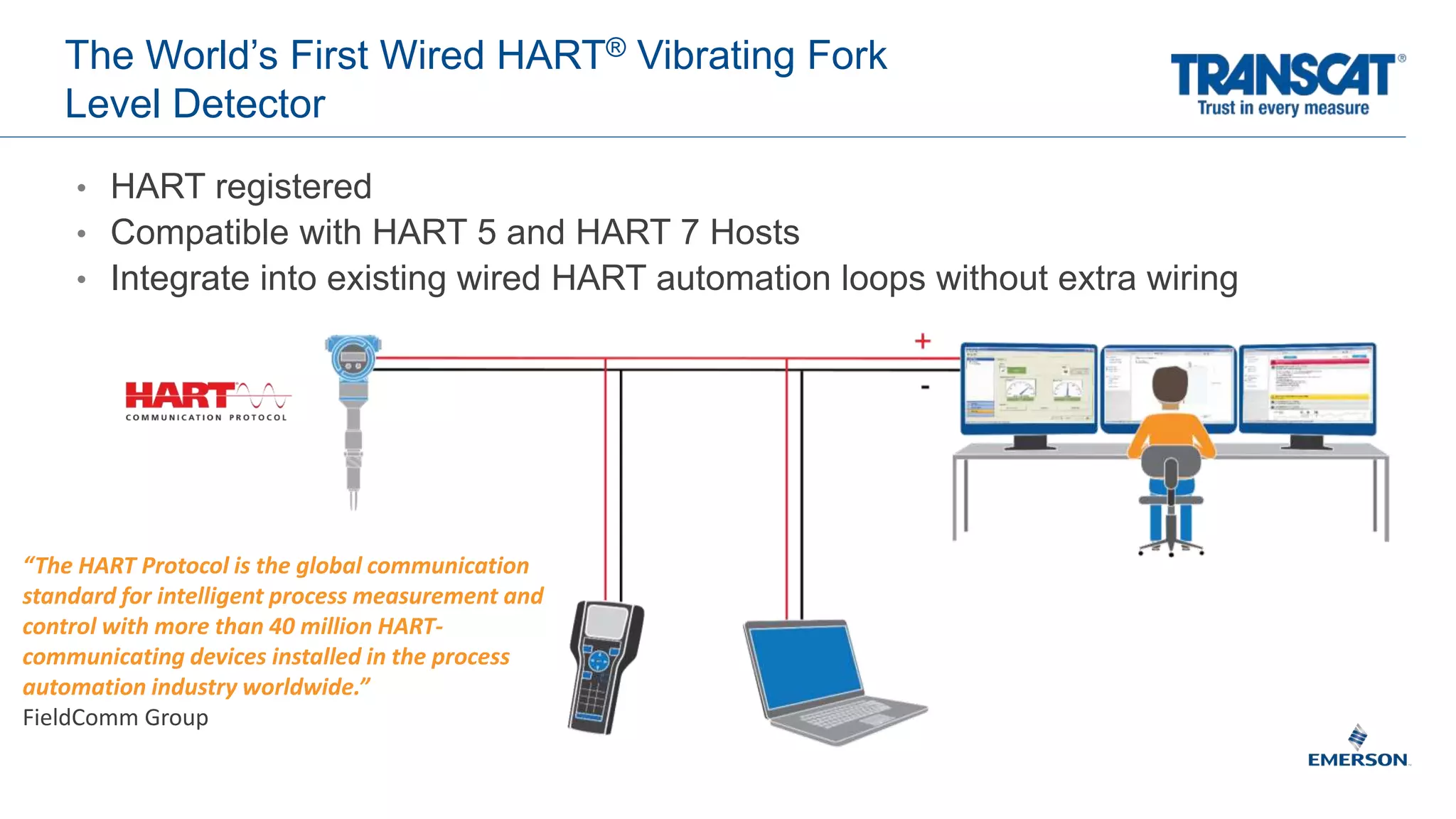

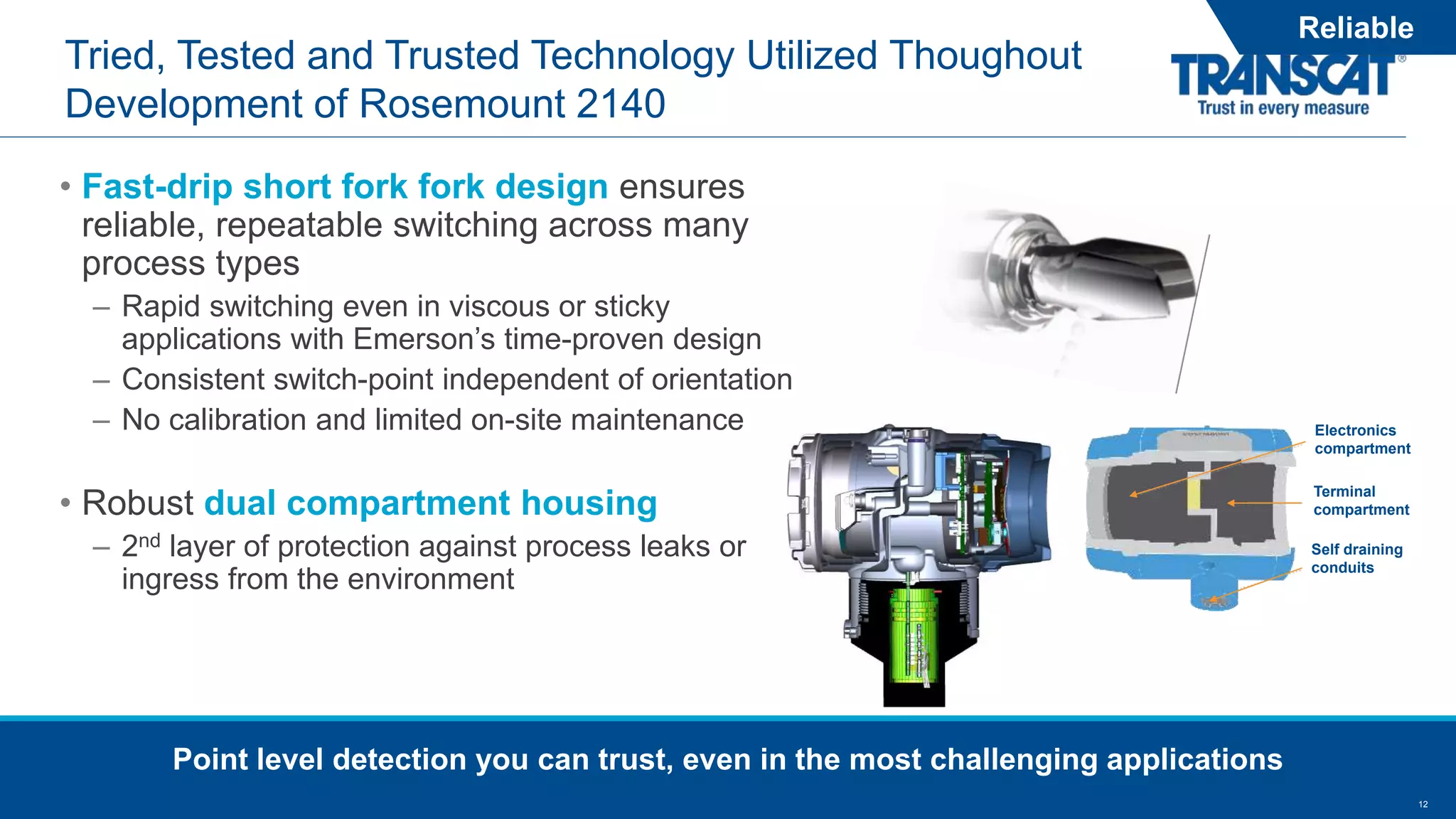

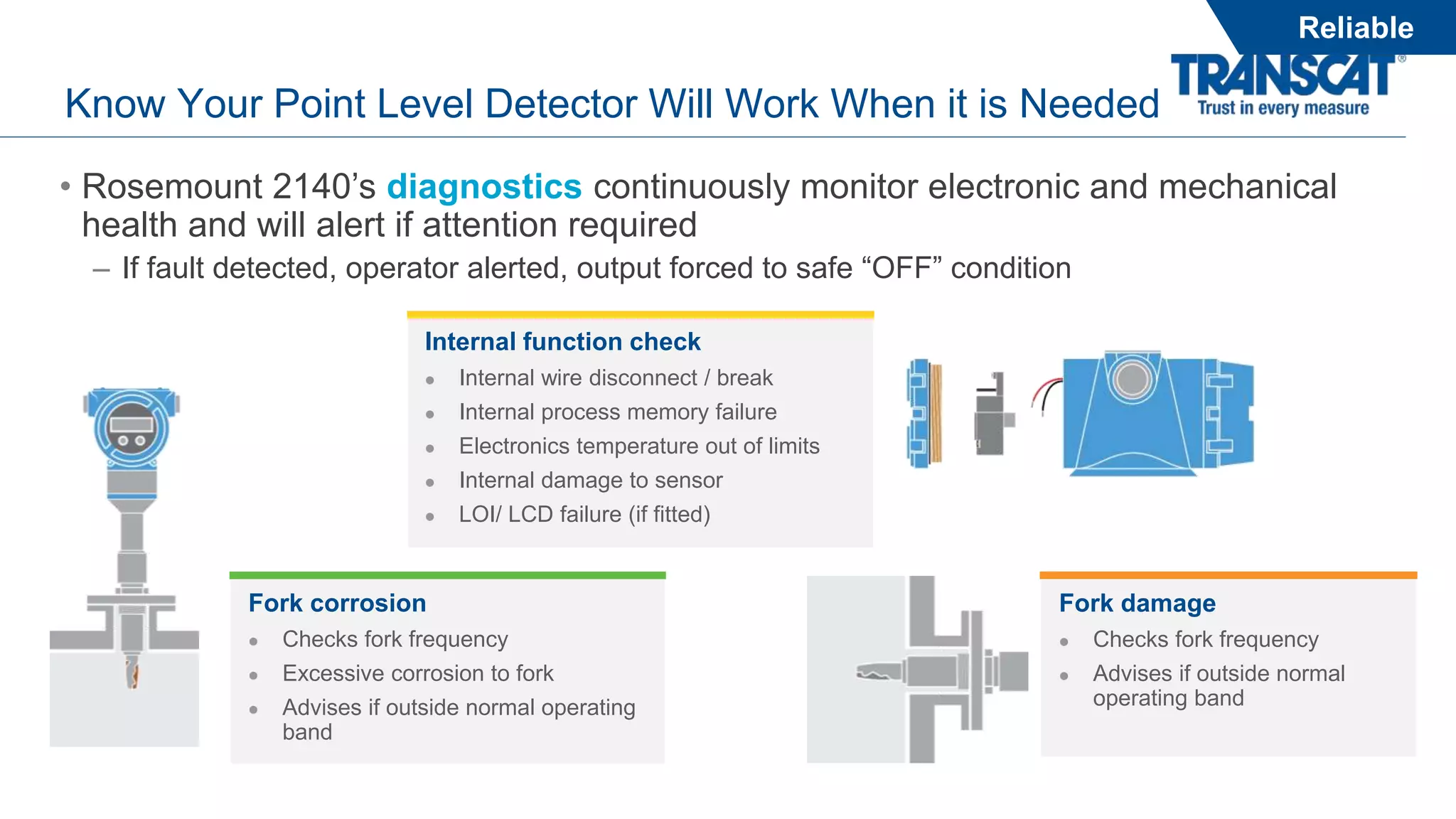

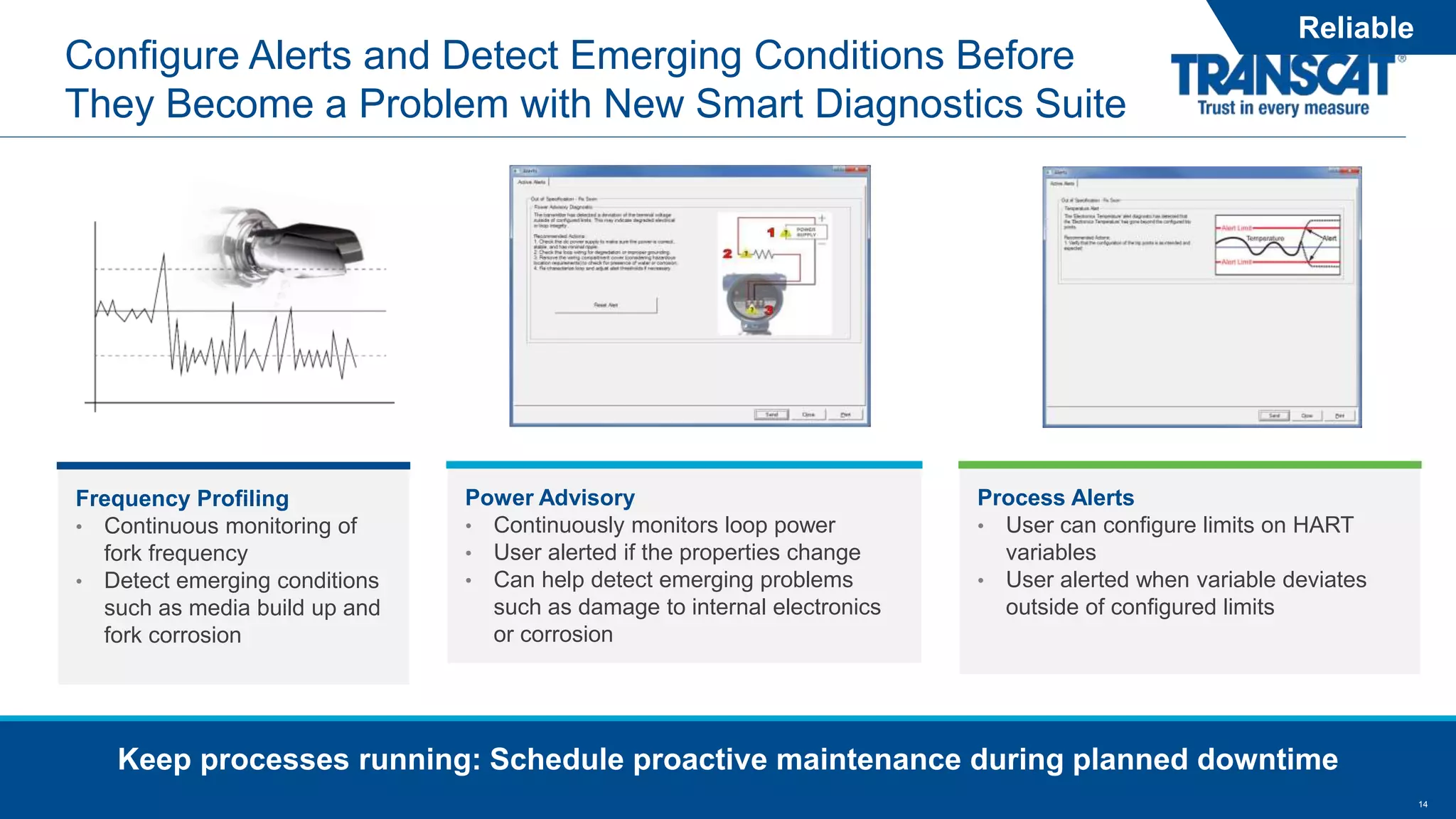

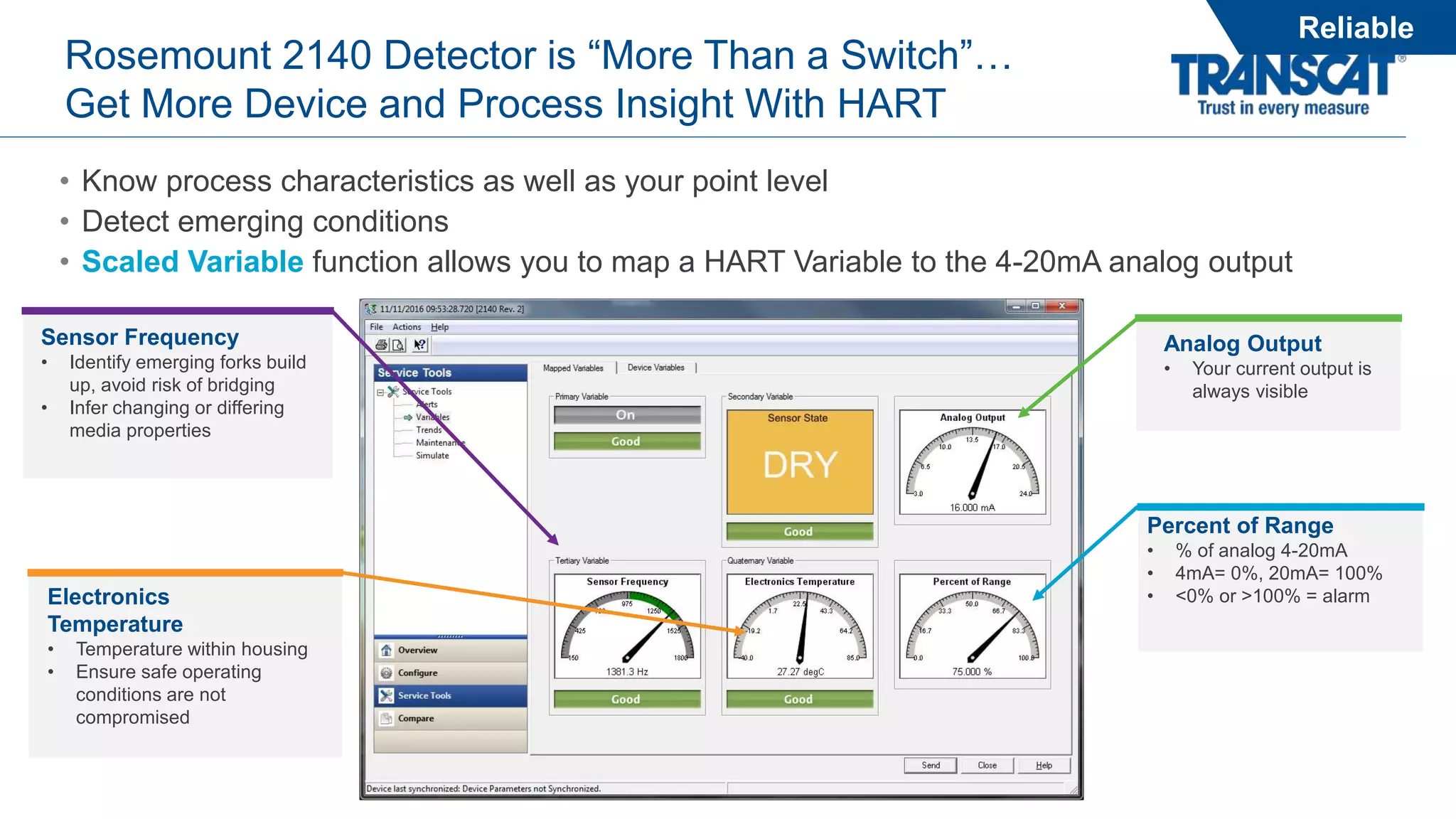

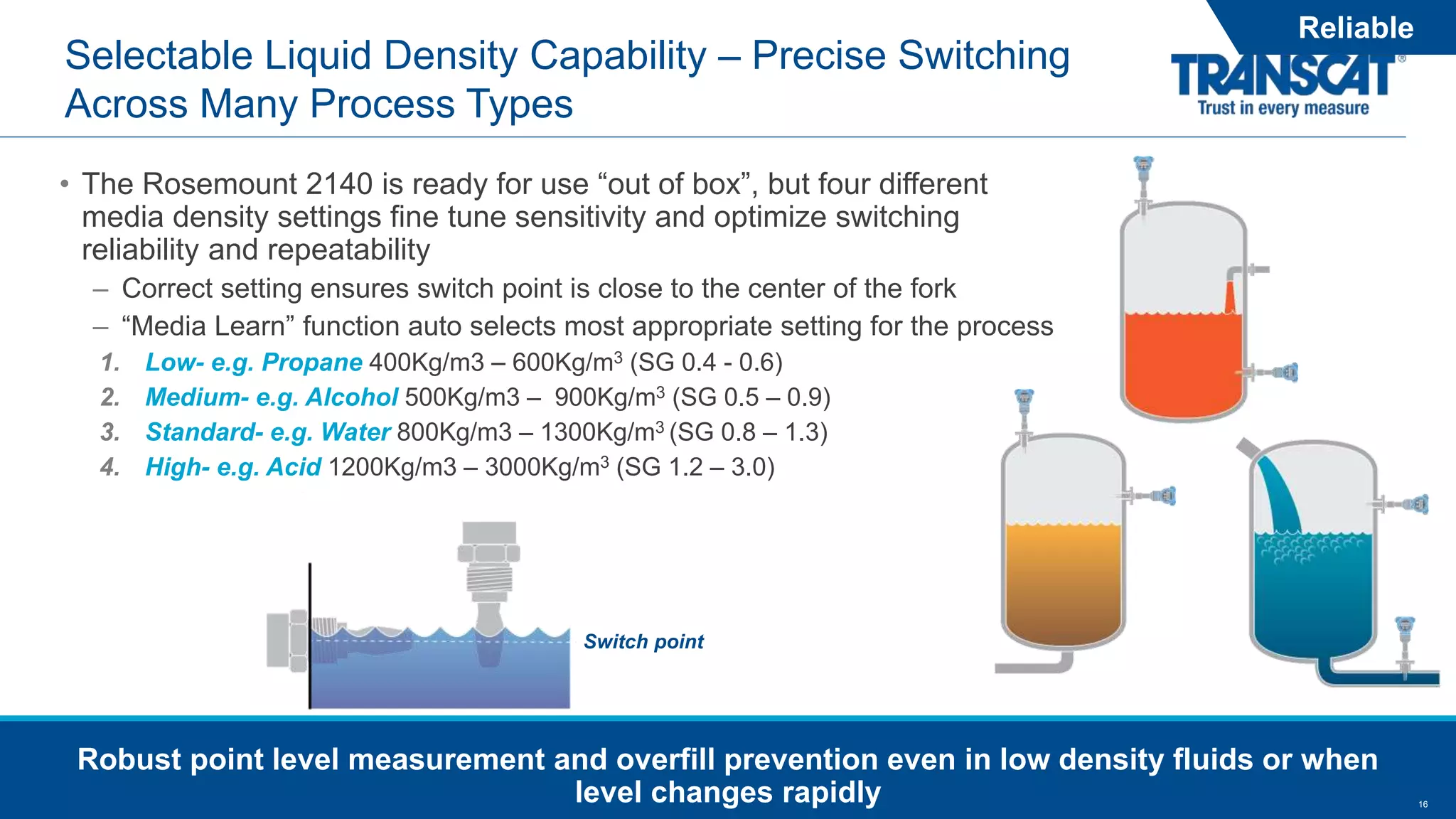

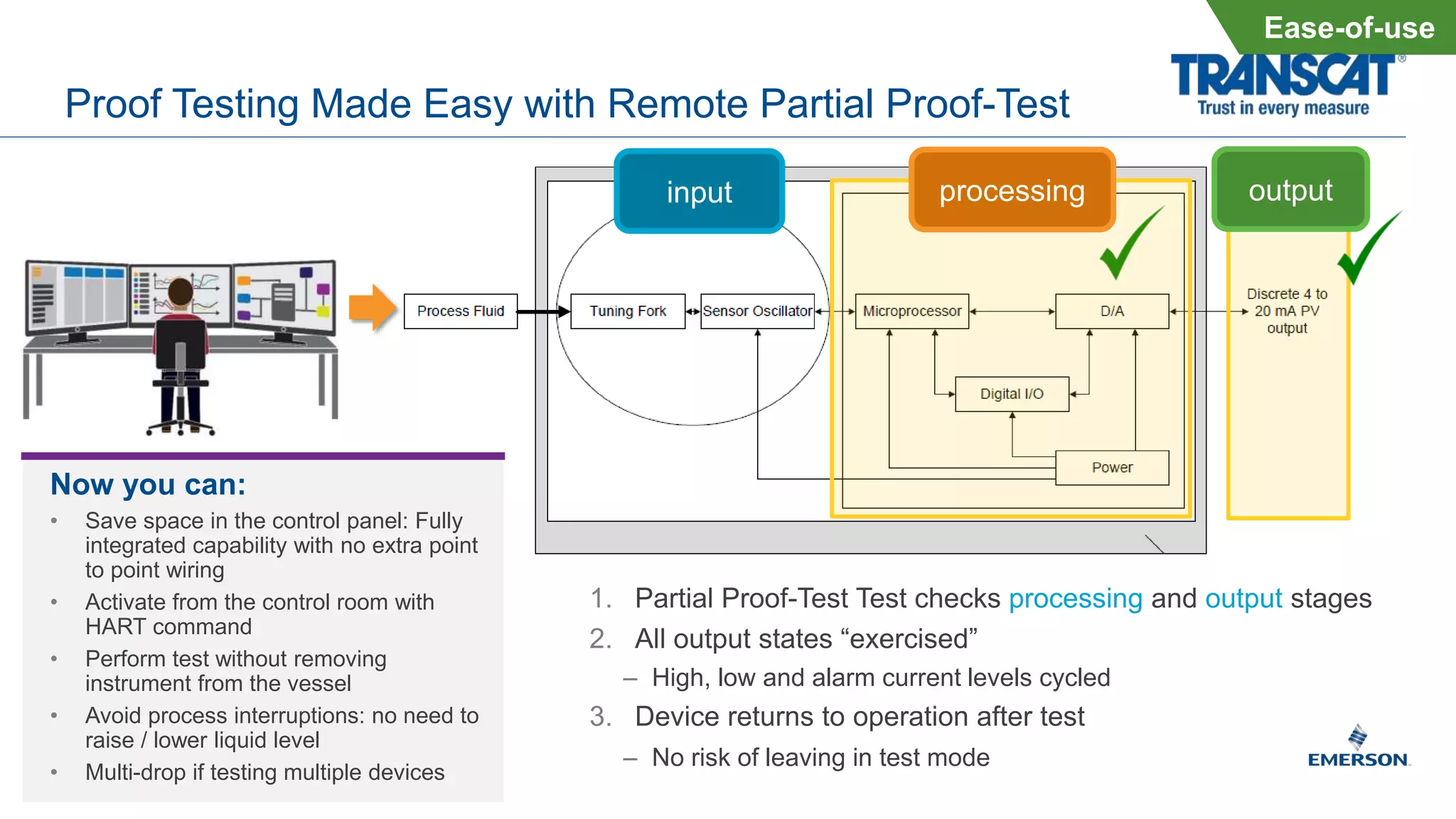

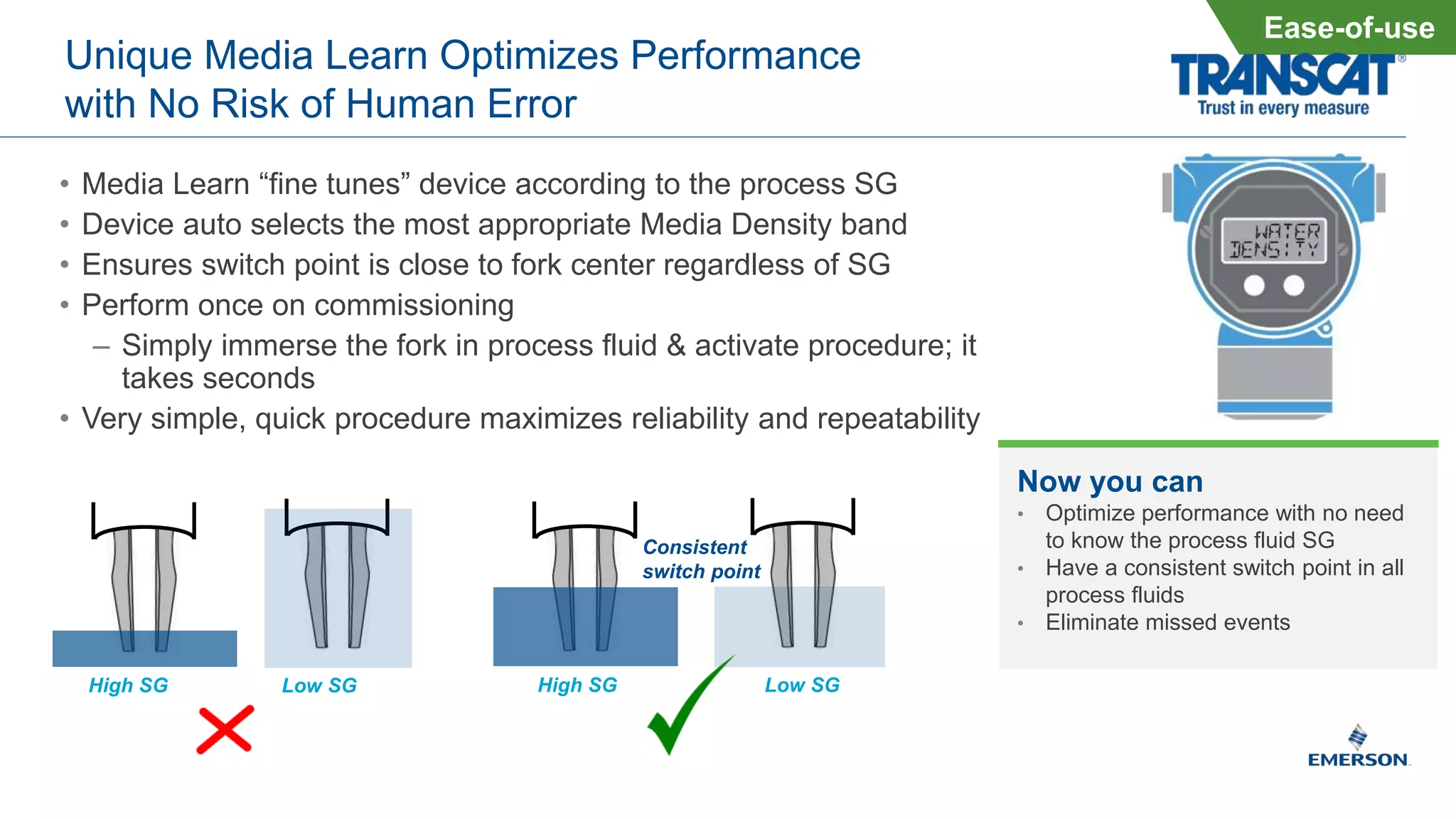

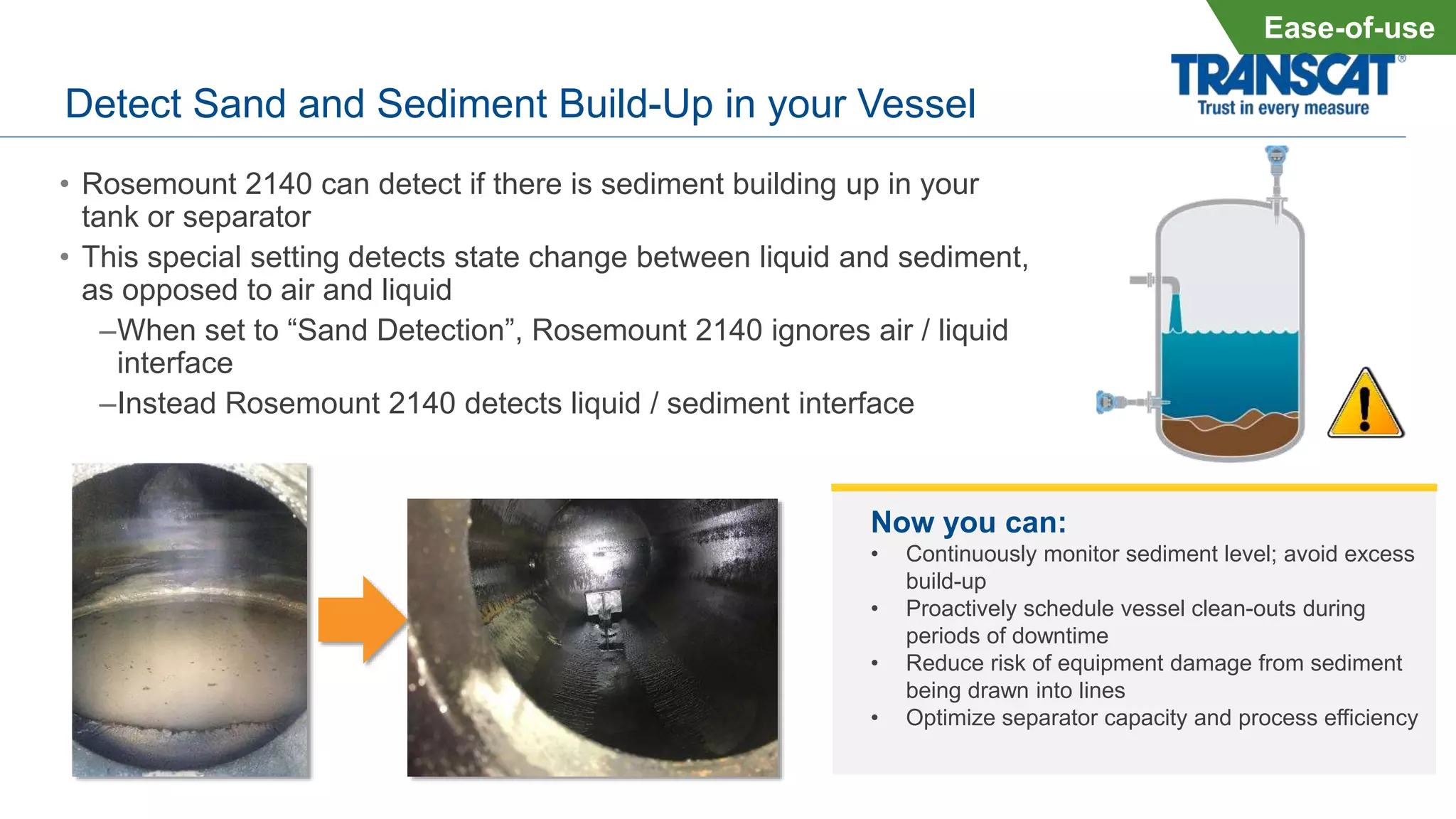

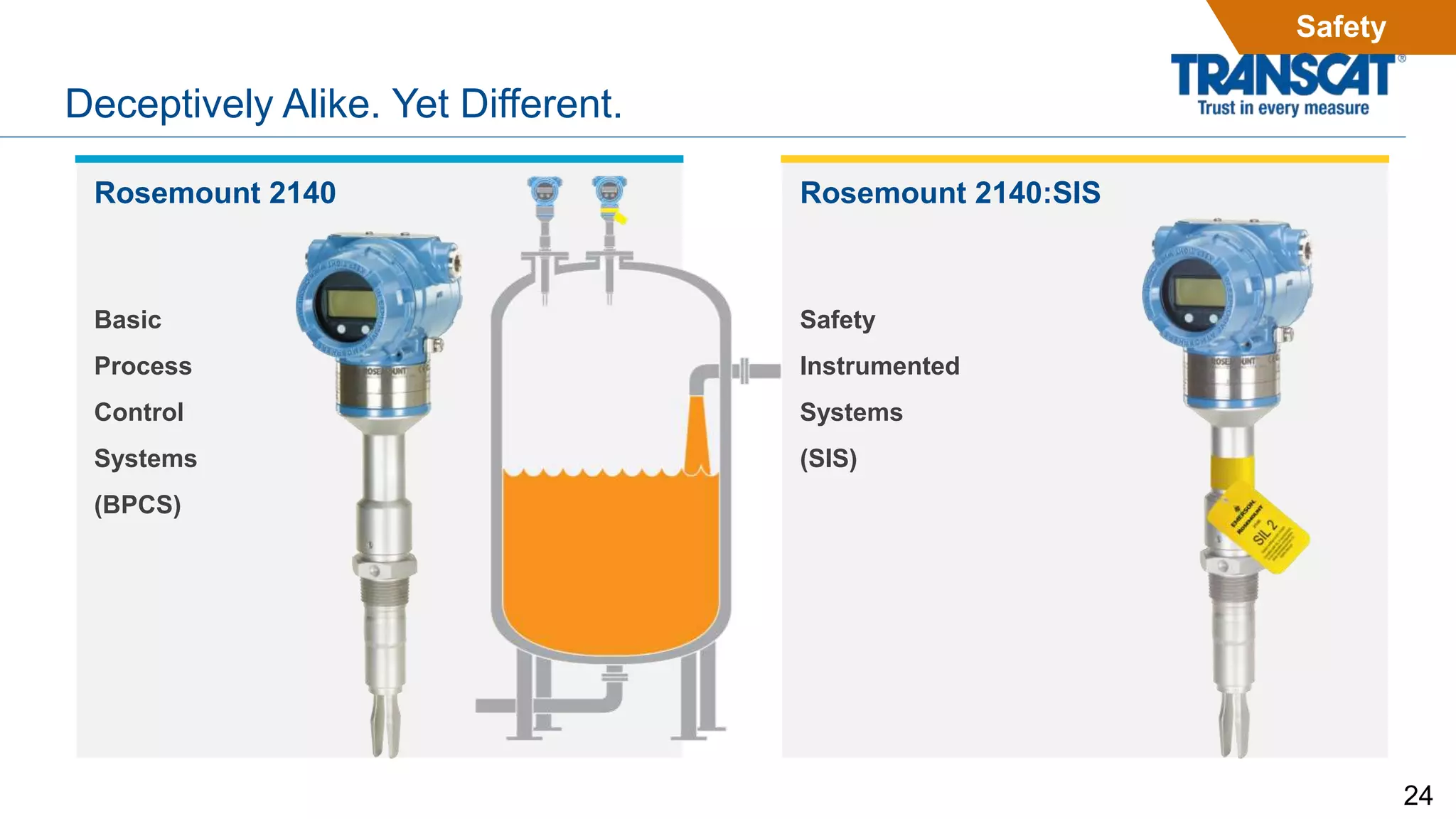

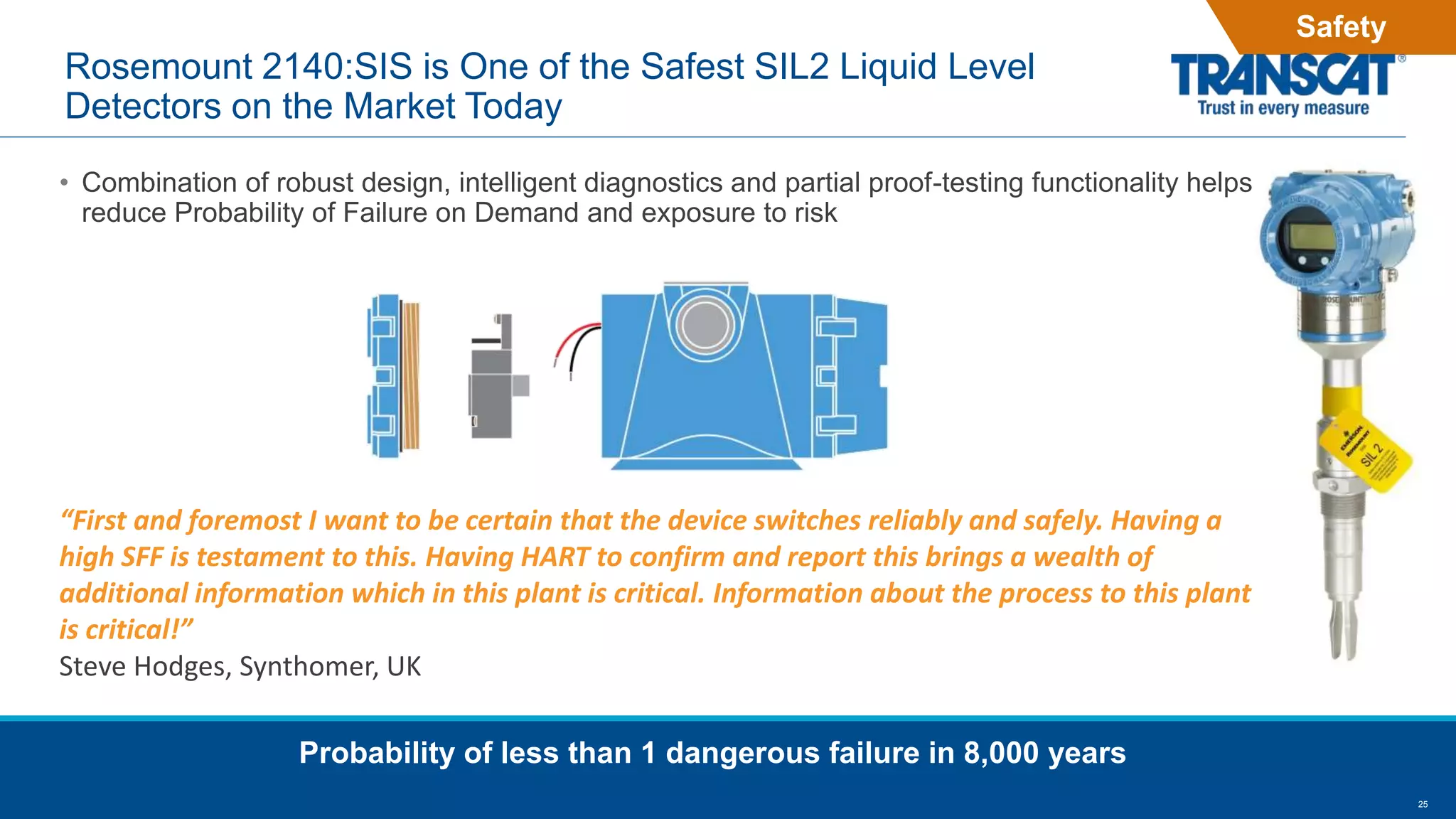

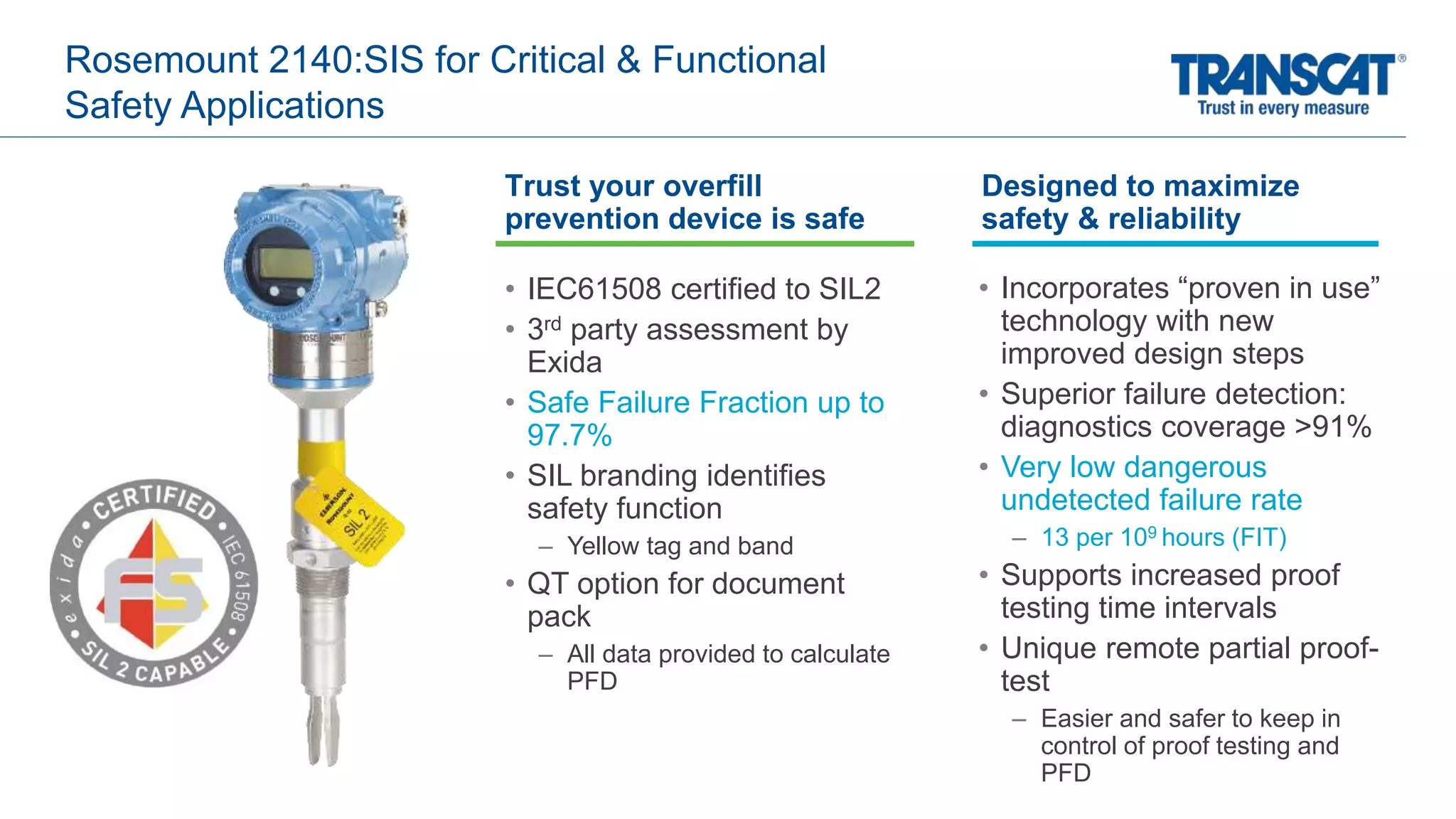

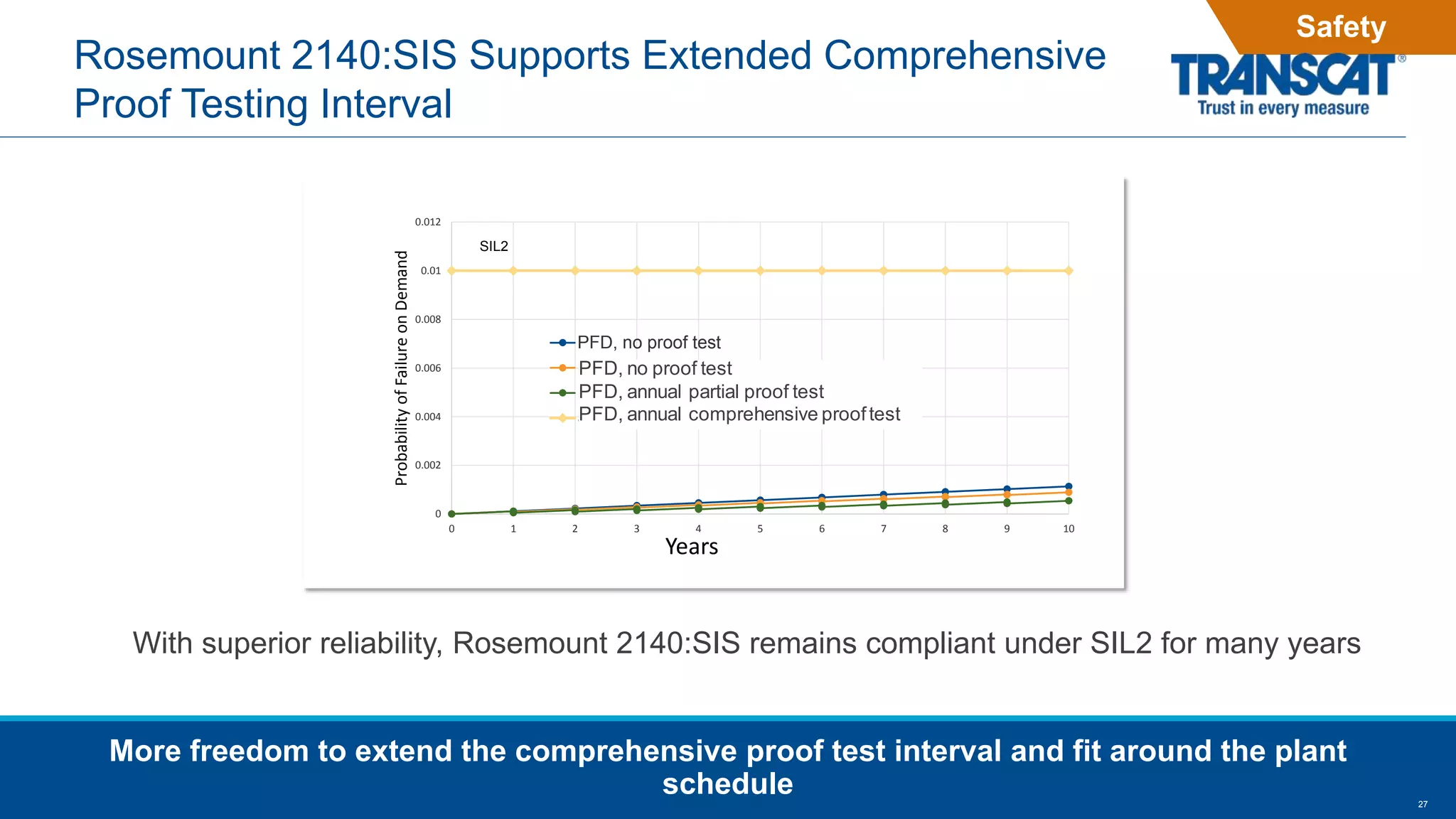

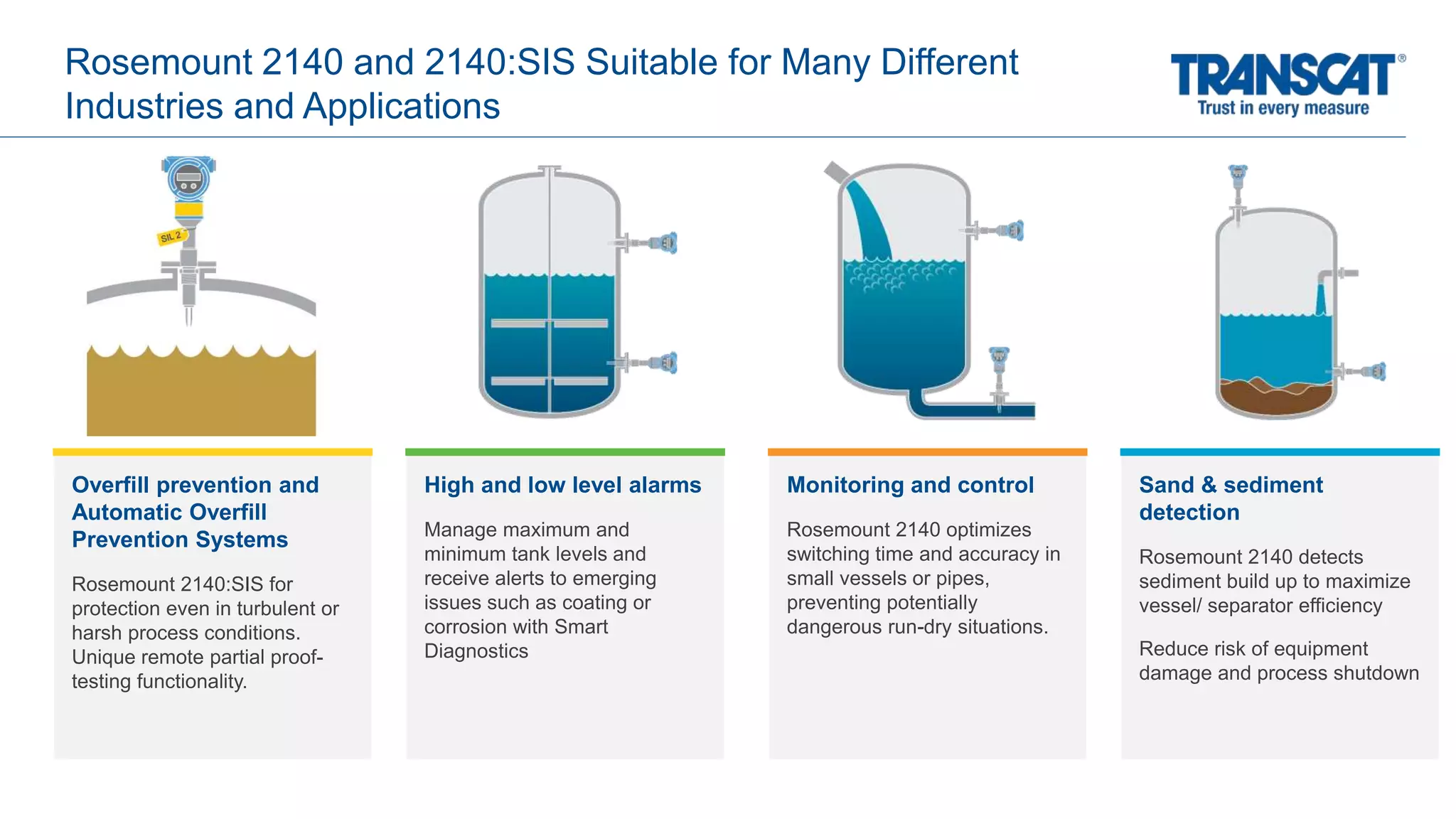

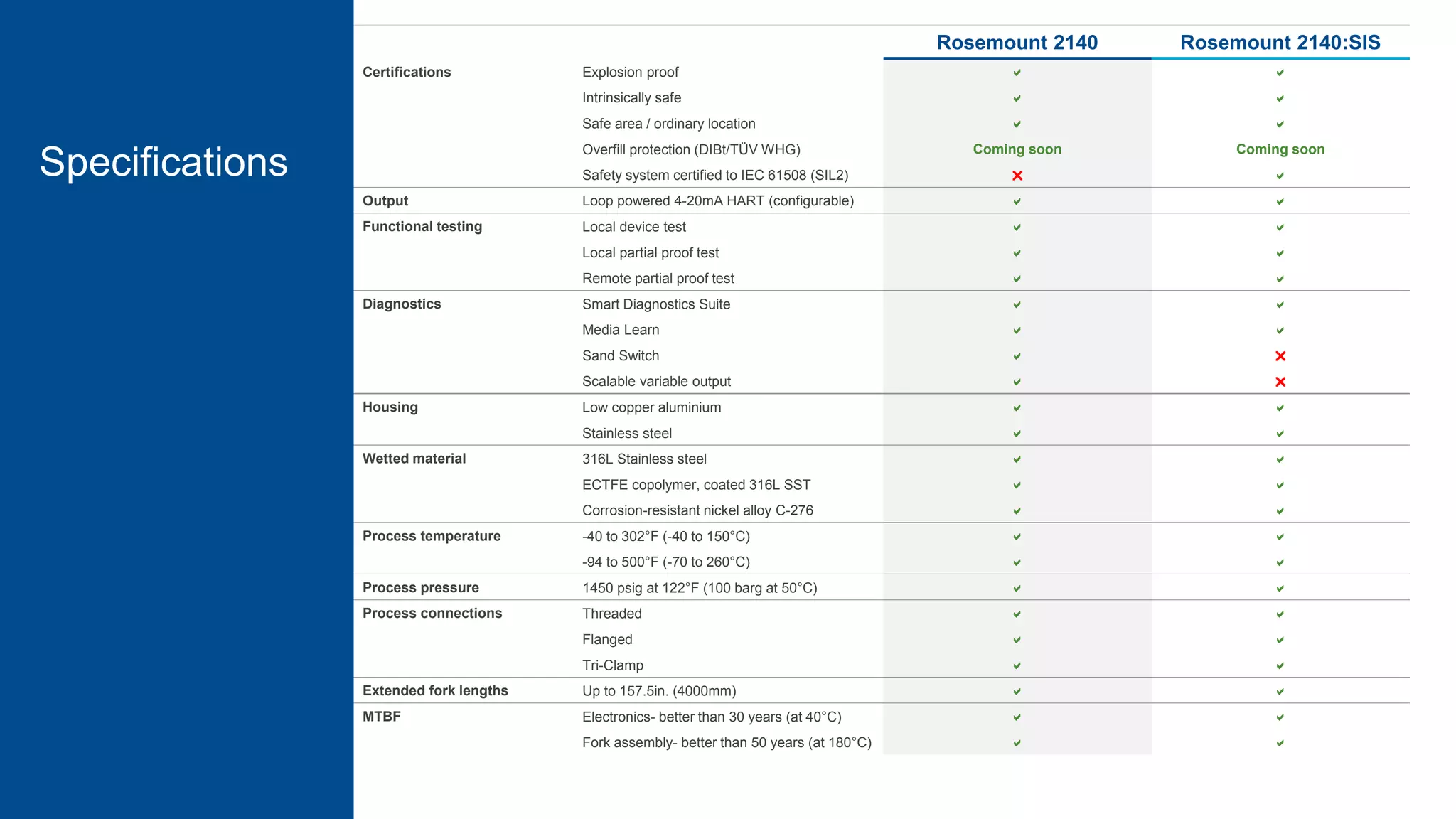

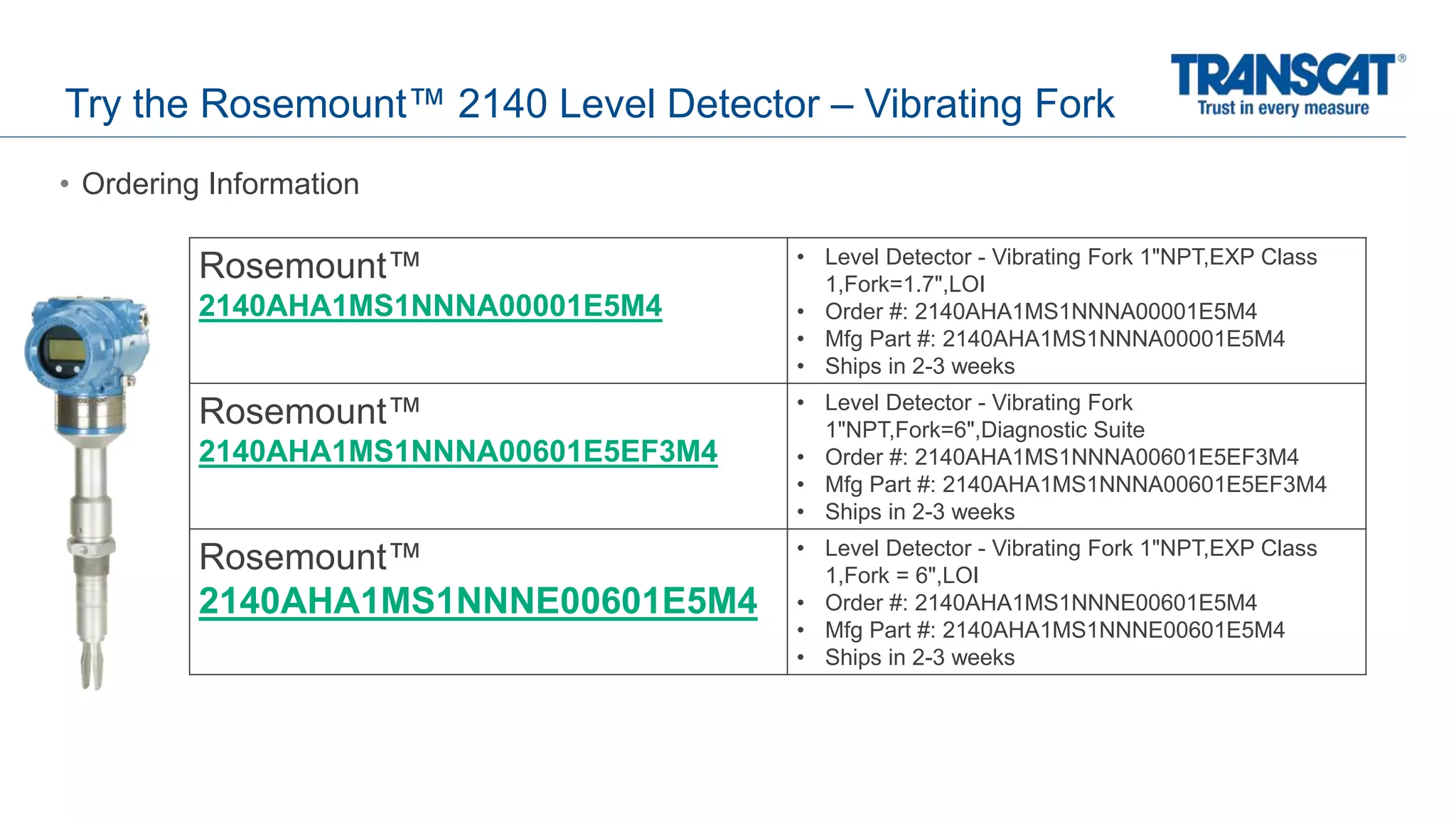

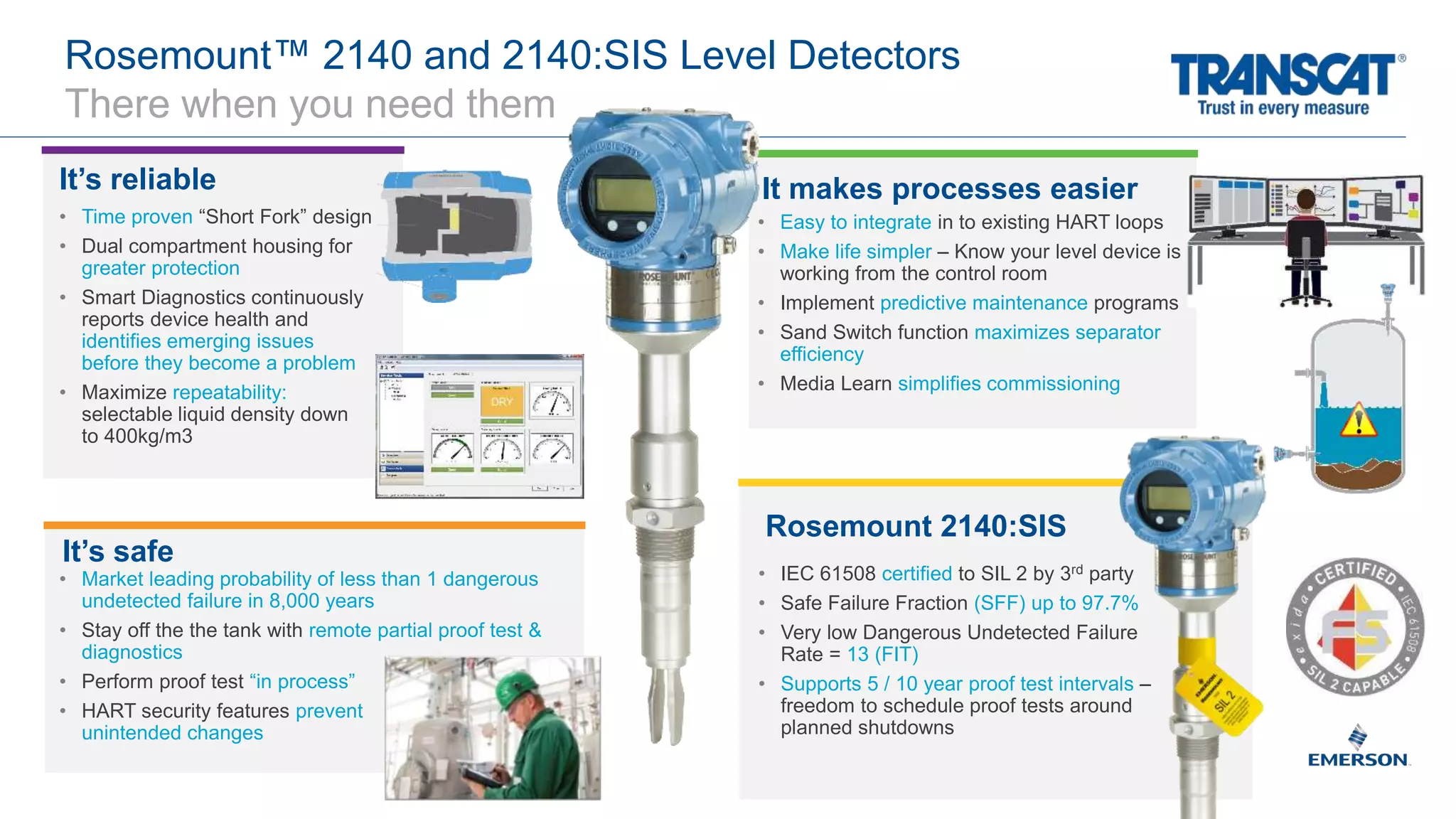

The document provides an overview of the Rosemount 2140 level detector, the world's first wired HART vibrating fork level detector designed for reliability and safety in various industries. It highlights the device's advanced diagnostics, ease of use, robust design, and smart functionality, which ensure accurate level measurement and preventative maintenance. Additionally, the detector supports sand and sediment detection, enhances process efficiency, and maintains compliance with safety standards, including IEC 61508 SIL2 certification.