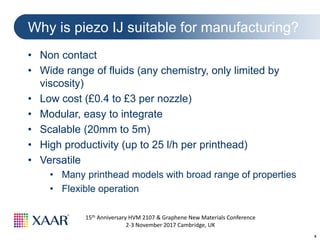

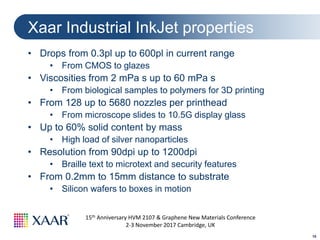

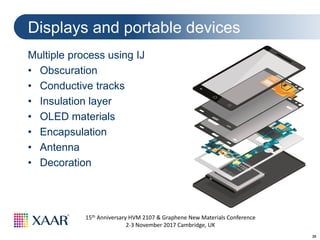

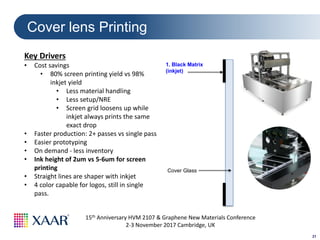

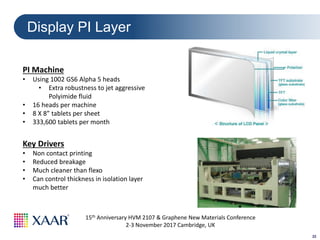

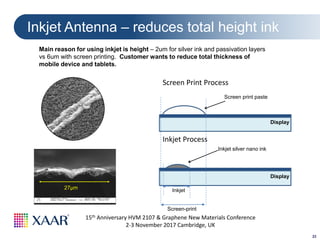

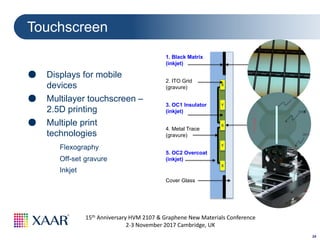

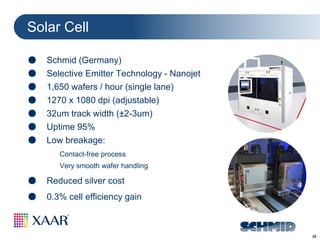

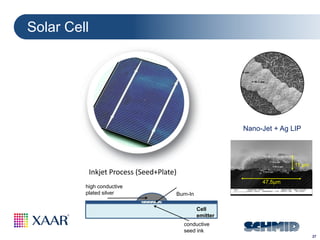

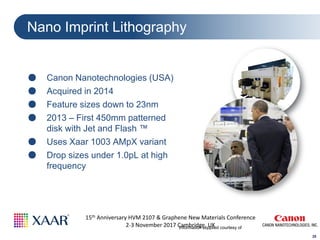

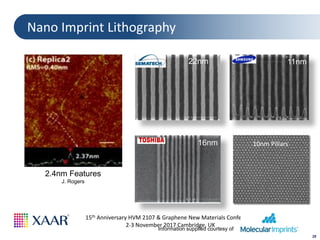

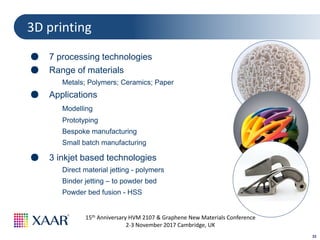

Xaar is a leading manufacturer of industrial inkjet printheads. Inkjet technology is increasingly being used in advanced manufacturing for applications such as decor, direct-to-shape printing, electronics, energy, construction, and 3D printing. Xaar's piezoelectric inkjet printheads offer advantages for manufacturing including non-contact printing, compatibility with a wide range of fluids, scalability, and high productivity. Case studies presented show how inkjet printing is being used for applications such as display manufacturing, solar cell production, and nanoimprint lithography.