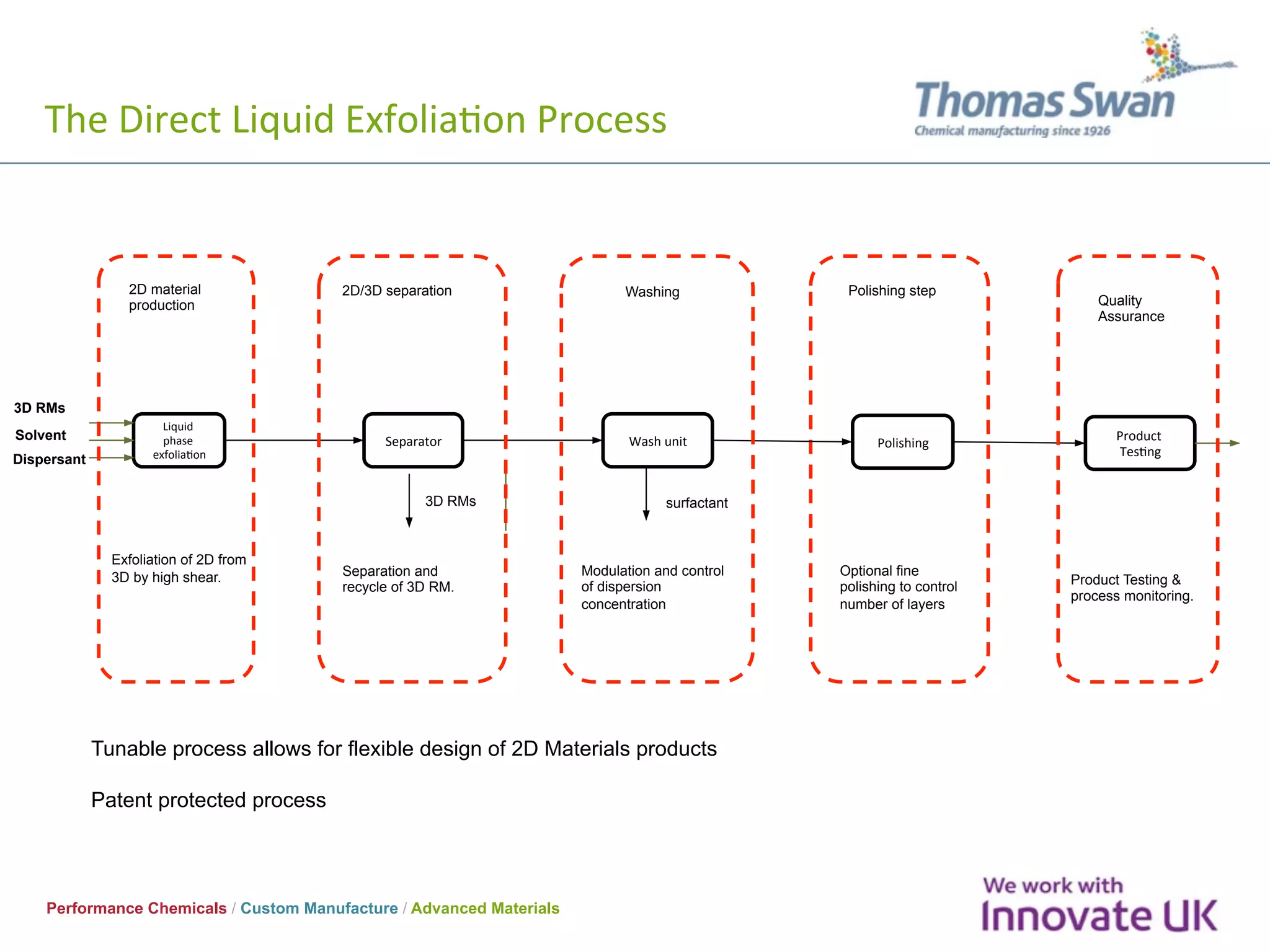

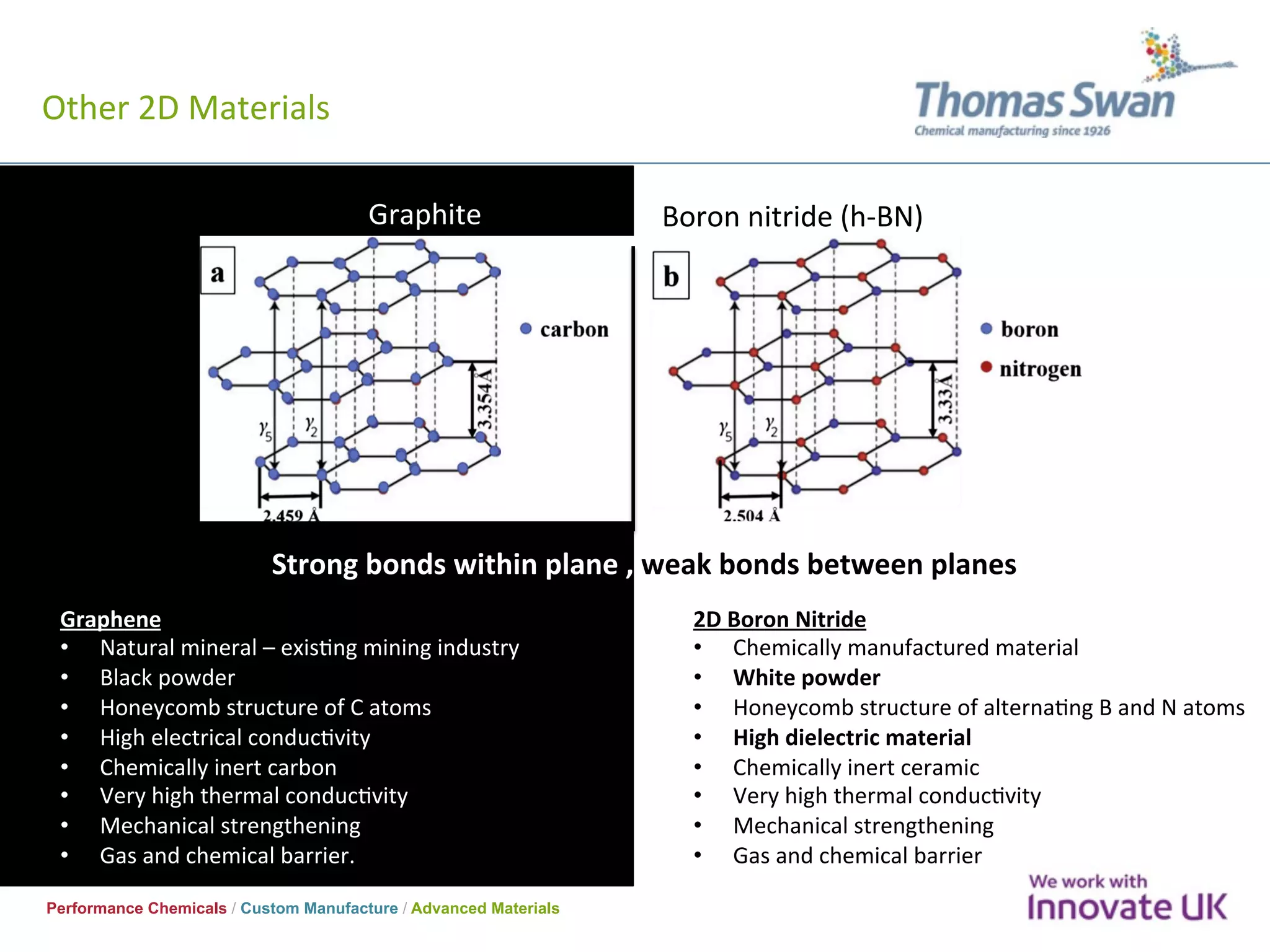

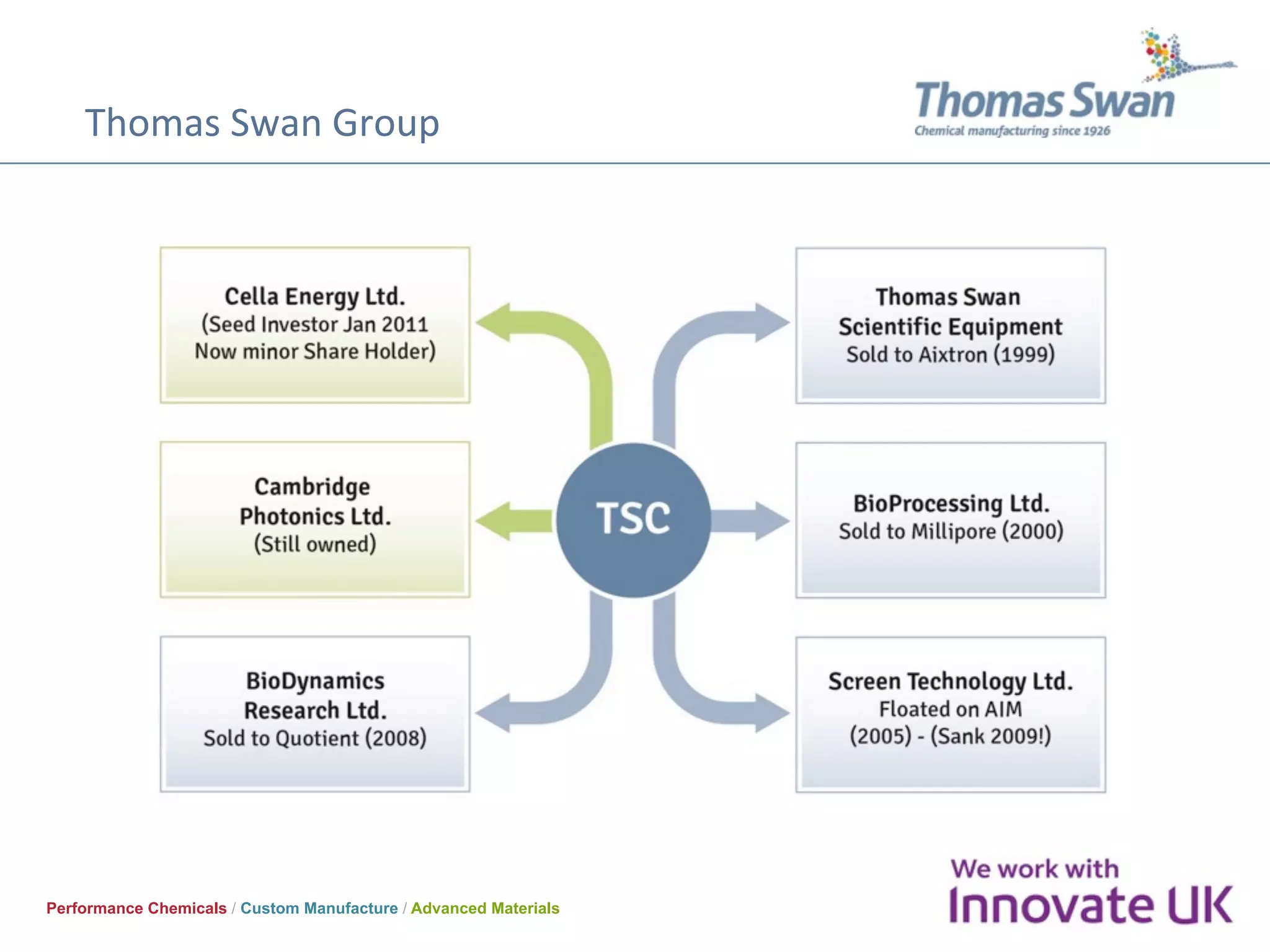

Thomas Swan & Co. Ltd. is a UK-based company that produces performance chemicals and advanced materials, including graphene. The company has a long history in the chemical industry and has been producing graphene through a scalable liquid phase exfoliation process since 2014. This process allows for the flexible production of a range of 2D materials, such as graphene, boron nitride, and molybdenum disulfide, in dispersions and powders. Thomas Swan sells these 2D materials and 2D material-enhanced composites for applications requiring improved mechanical, thermal, and barrier properties.

![What is InnovaOon to Thomas Swan?

Performance Chemicals / Custom Manufacture / Advanced Materials

“Innovation is any new idea, no

matter how small or large, that

adds value [to the company].”](https://image.slidesharecdn.com/1hvmgnm17swan-201012151315/75/Materials-and-processes-8-2048.jpg)