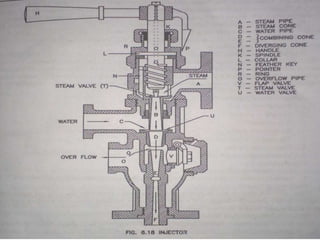

The injector is a device that uses steam to feed water into a boiler. It works by steam flowing into a steam cone, creating a vacuum that draws in water. The water and steam mix and accelerate before entering the boiler. A spindle controls the position of the steam cone to regulate the steam and water mixture based on steam pressure. The injector is a simple, compact, and efficient way to feed water to a boiler using steam power with no moving parts.