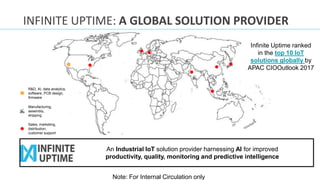

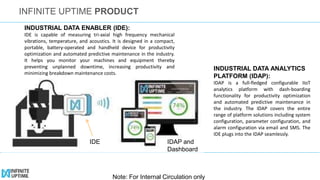

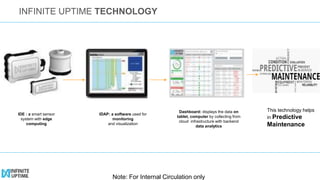

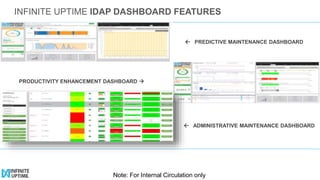

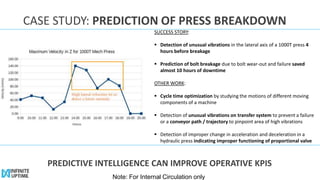

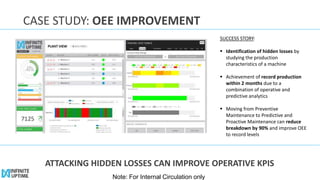

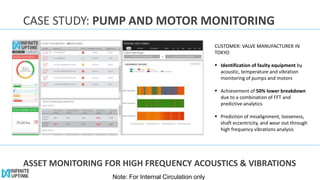

Infinite Uptime is a global Industrial IoT solution provider that harnesses AI to improve productivity, quality, monitoring and predictive intelligence for manufacturing customers. It has sales, support and R&D teams located in major cities in India and the US. Infinite Uptime's key products are the IDE sensor and IDAP analytics platform, which combine to enable predictive maintenance by monitoring machine vibrations, temperatures and other metrics. Case studies demonstrate how Infinite Uptime's solutions have helped customers reduce downtime, lower costs, improve OEE and detect asset failures before they occur.