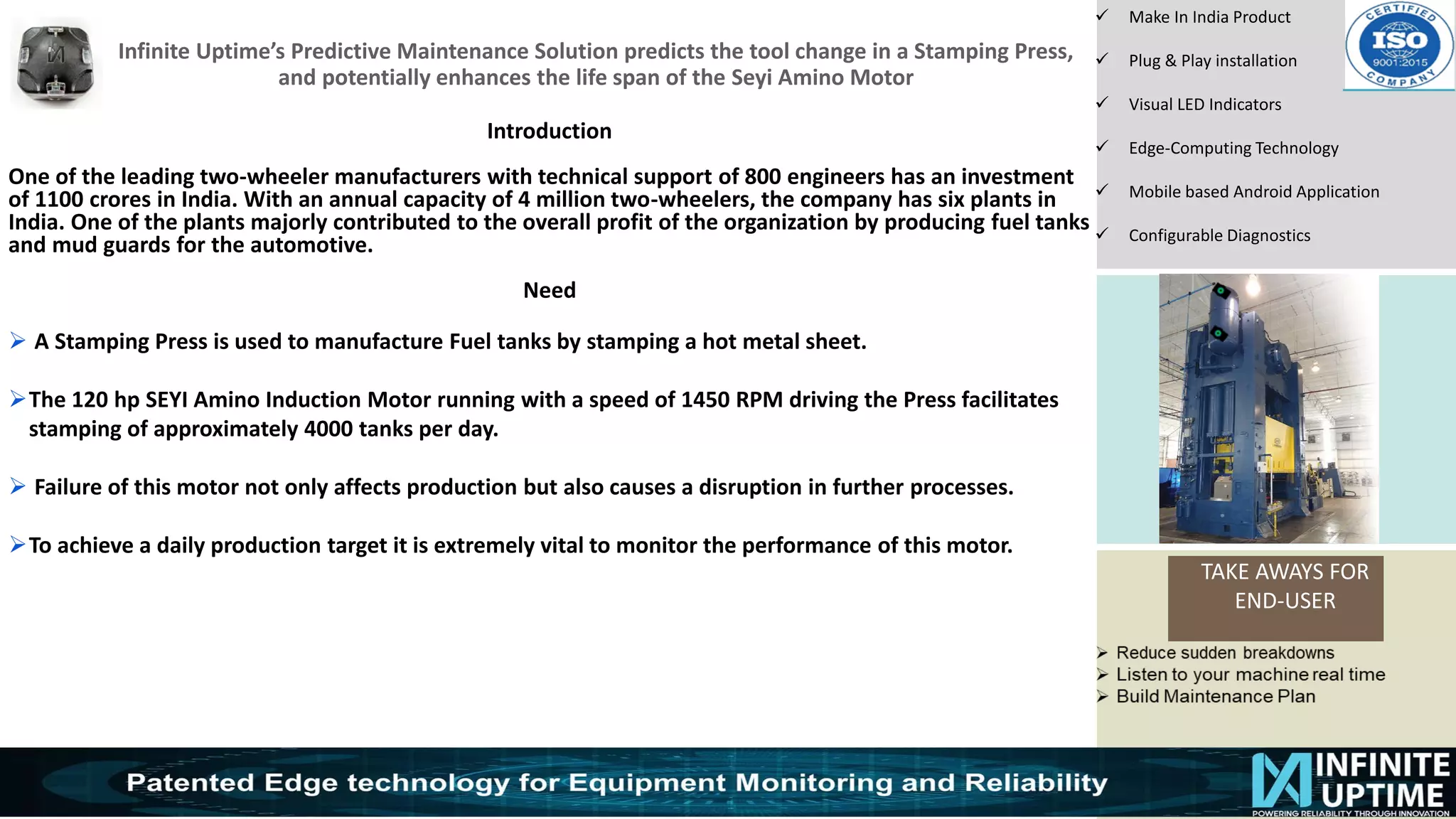

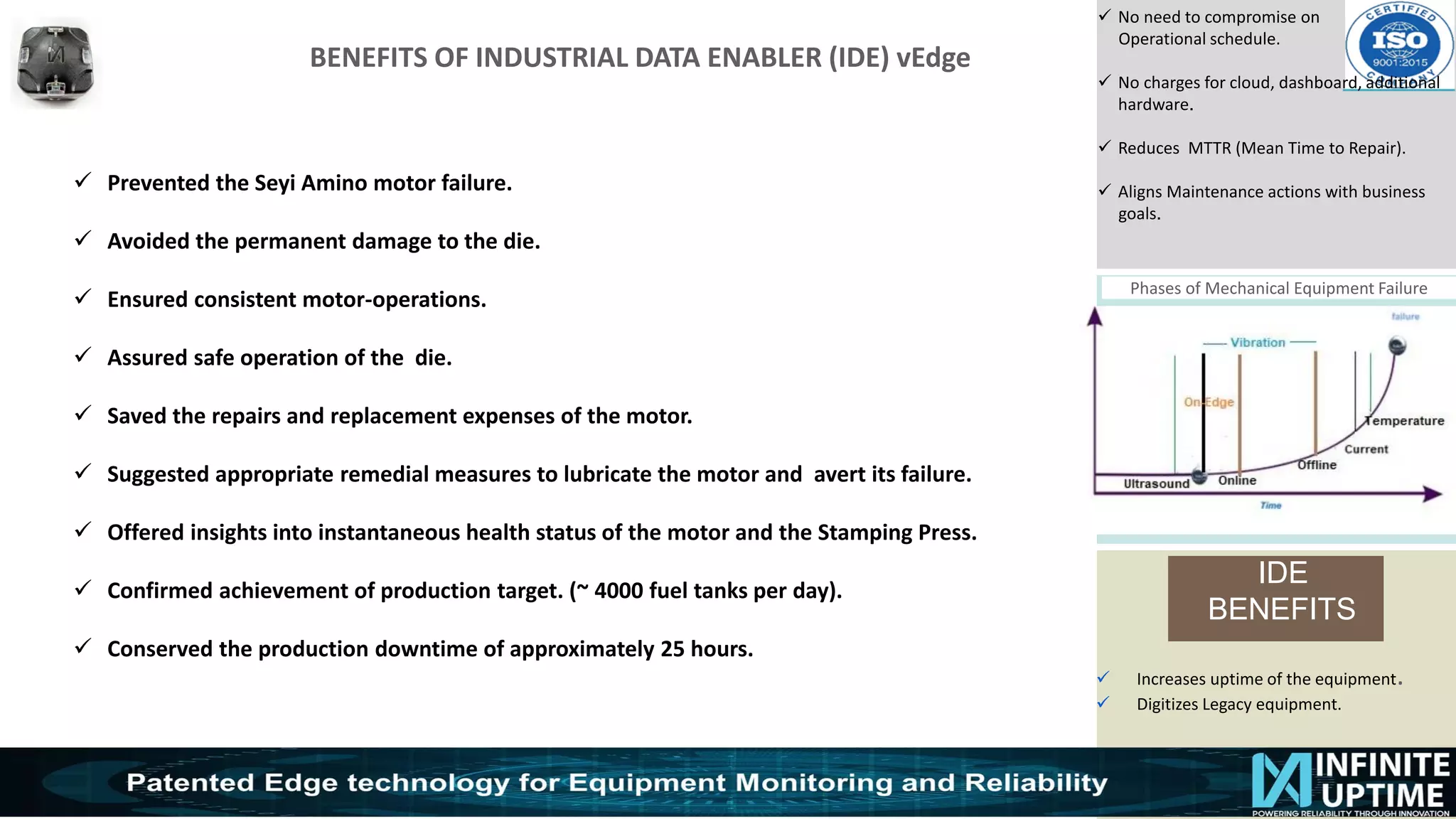

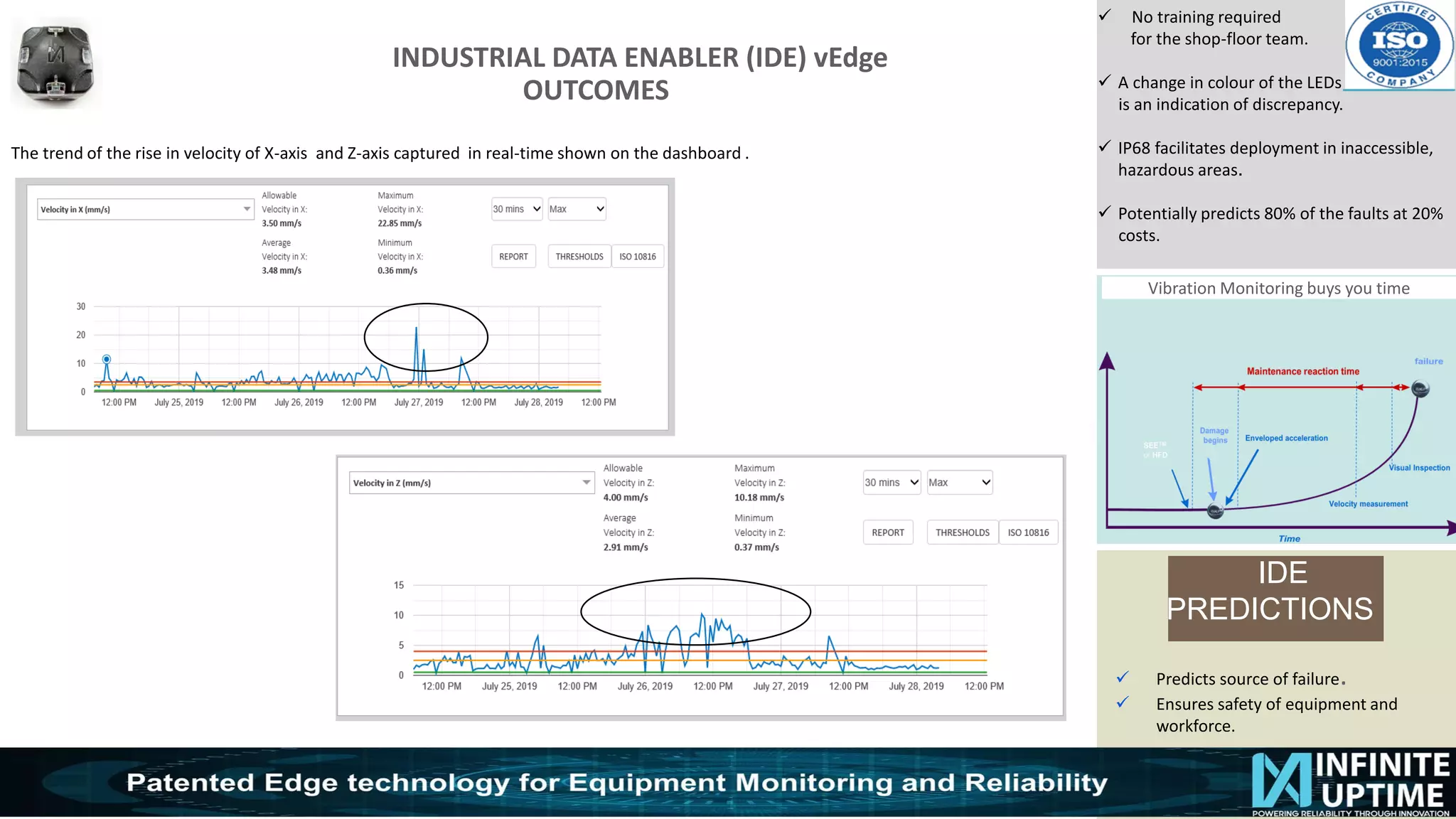

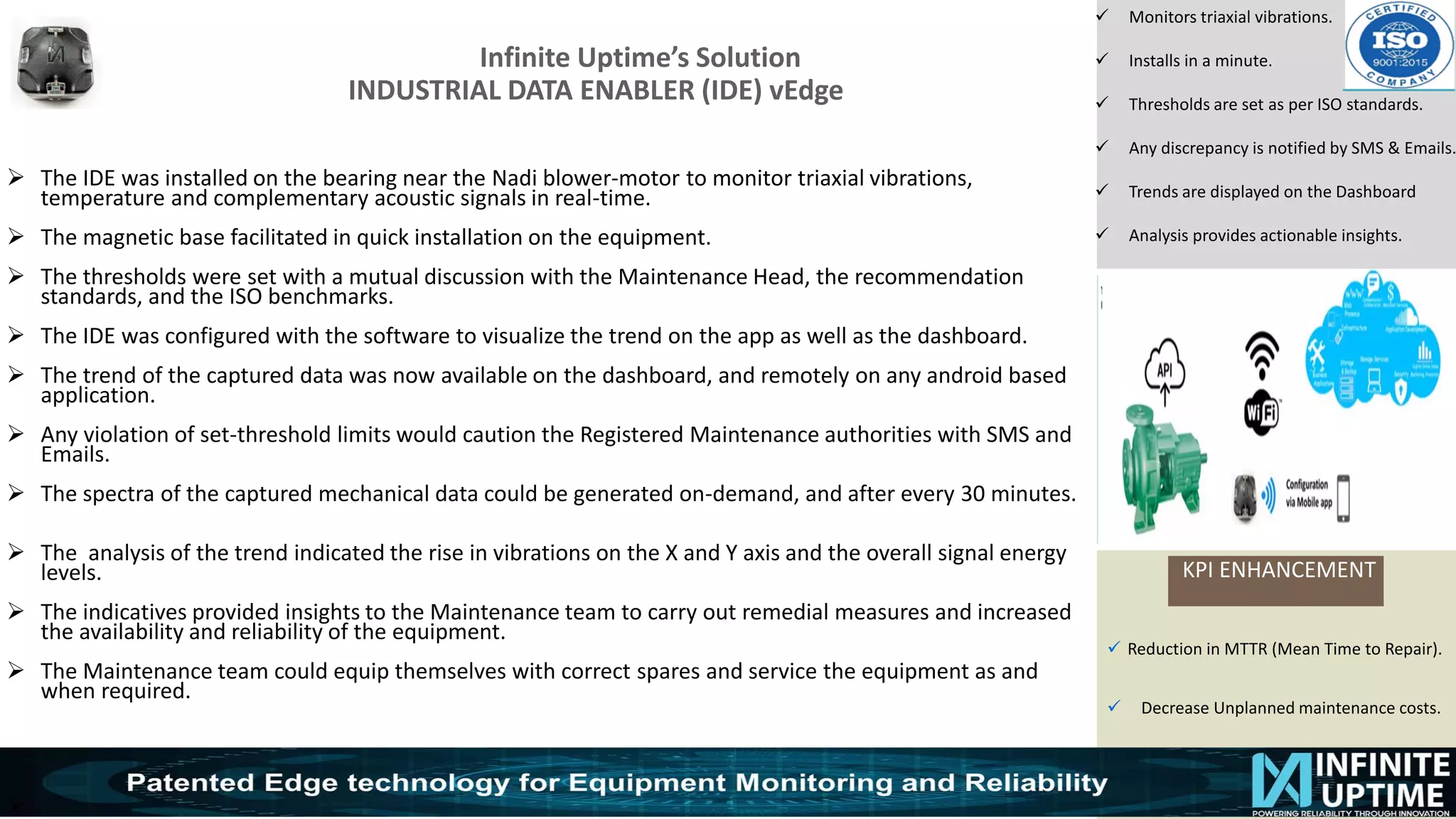

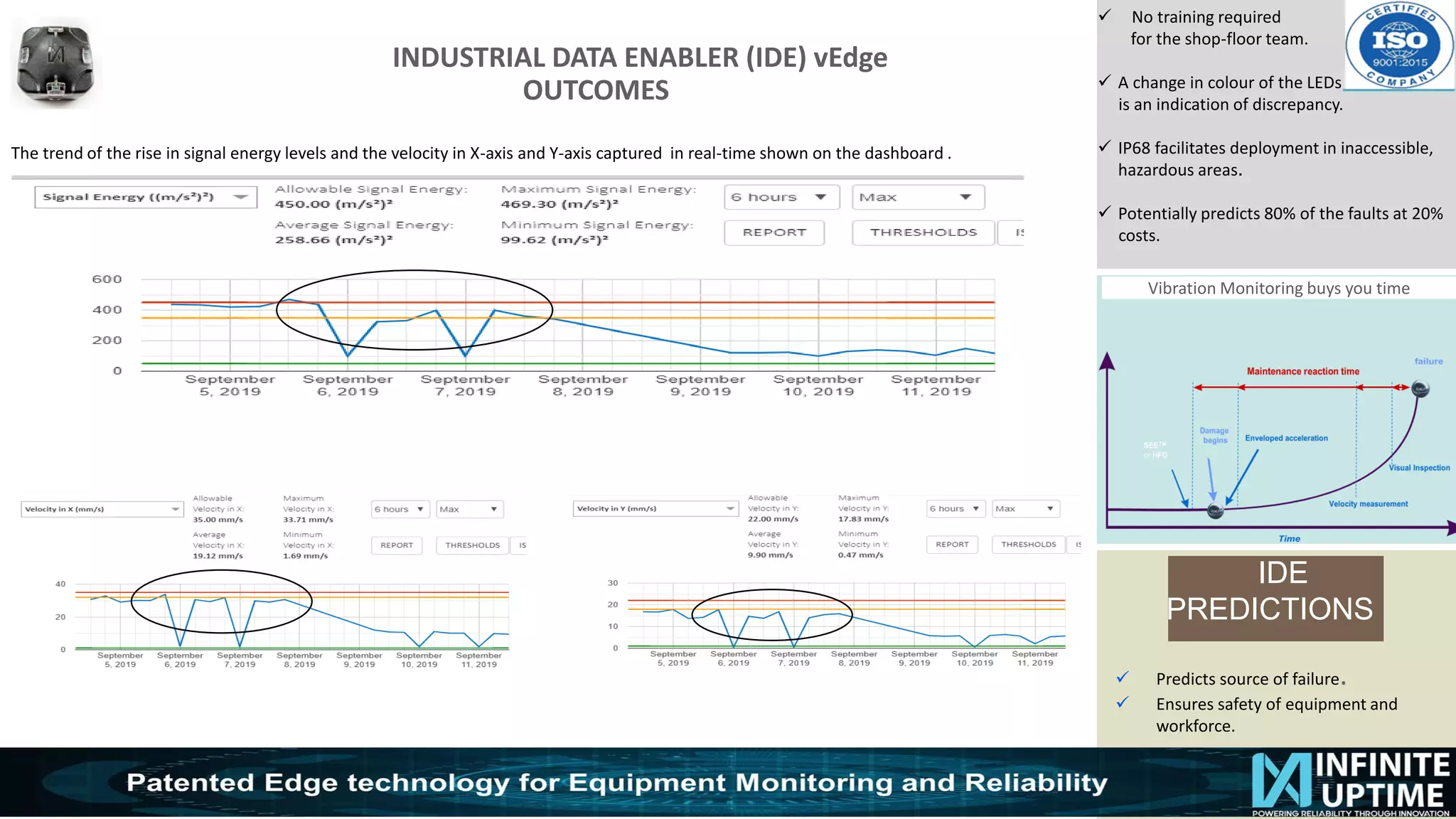

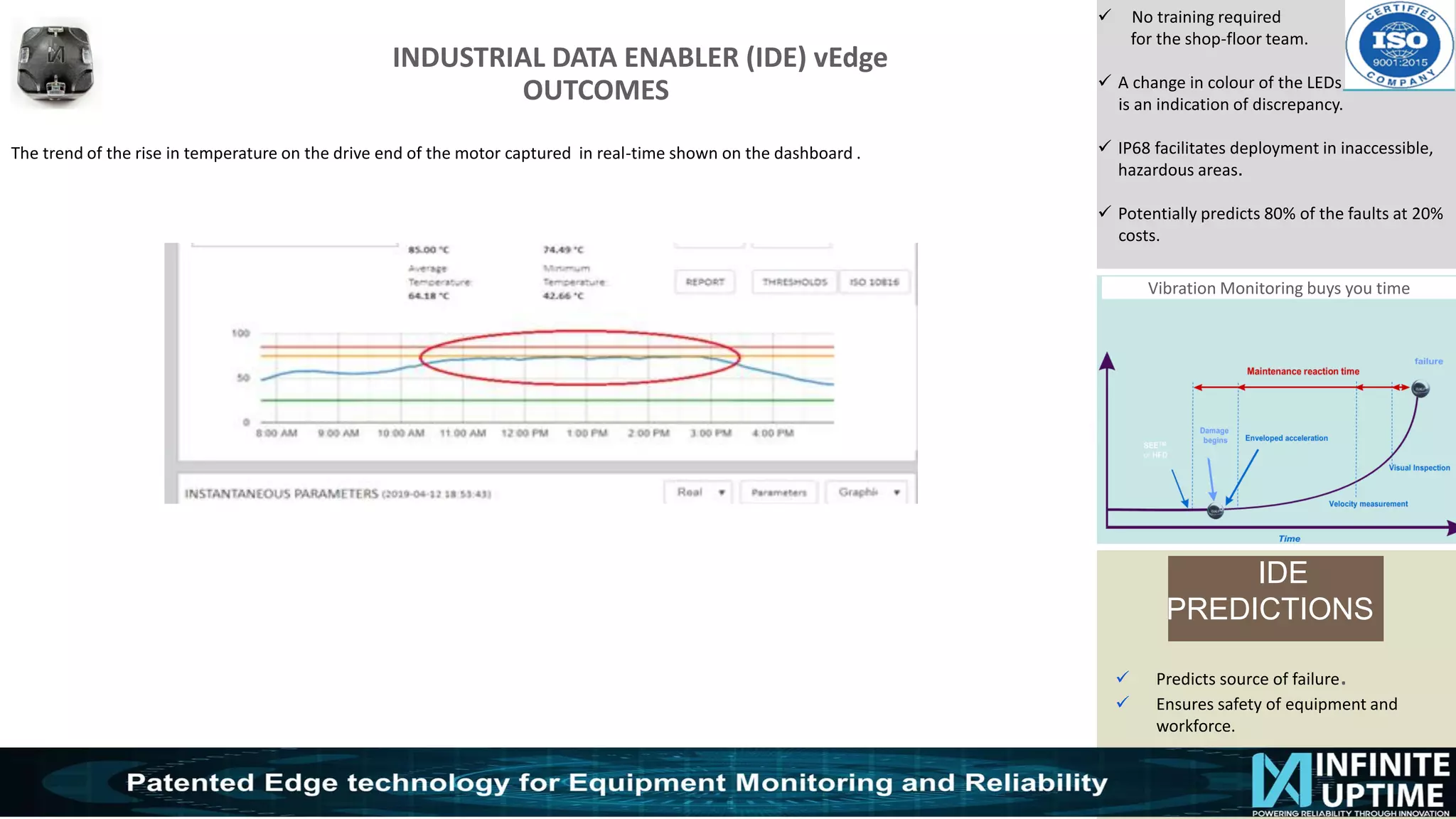

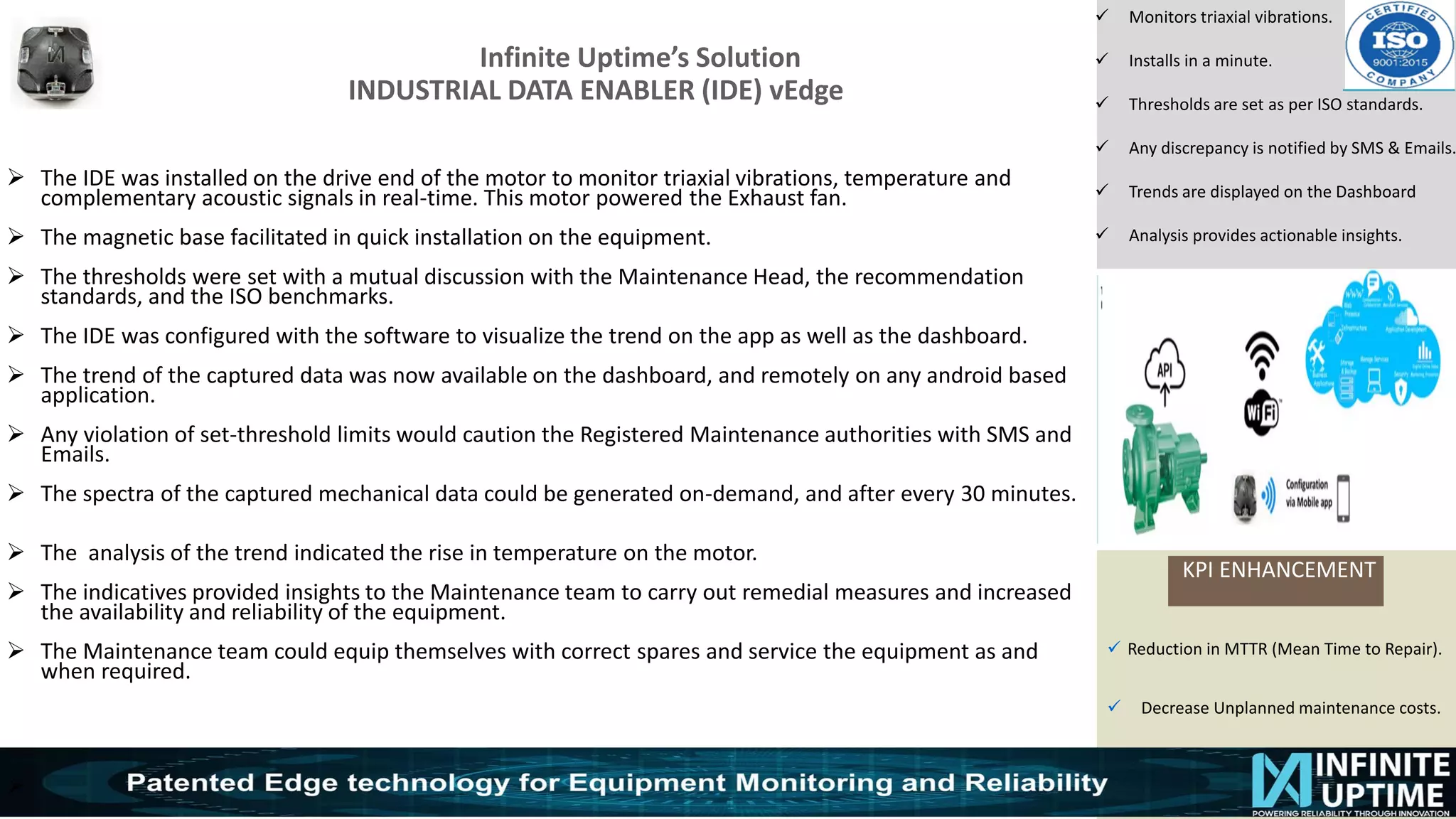

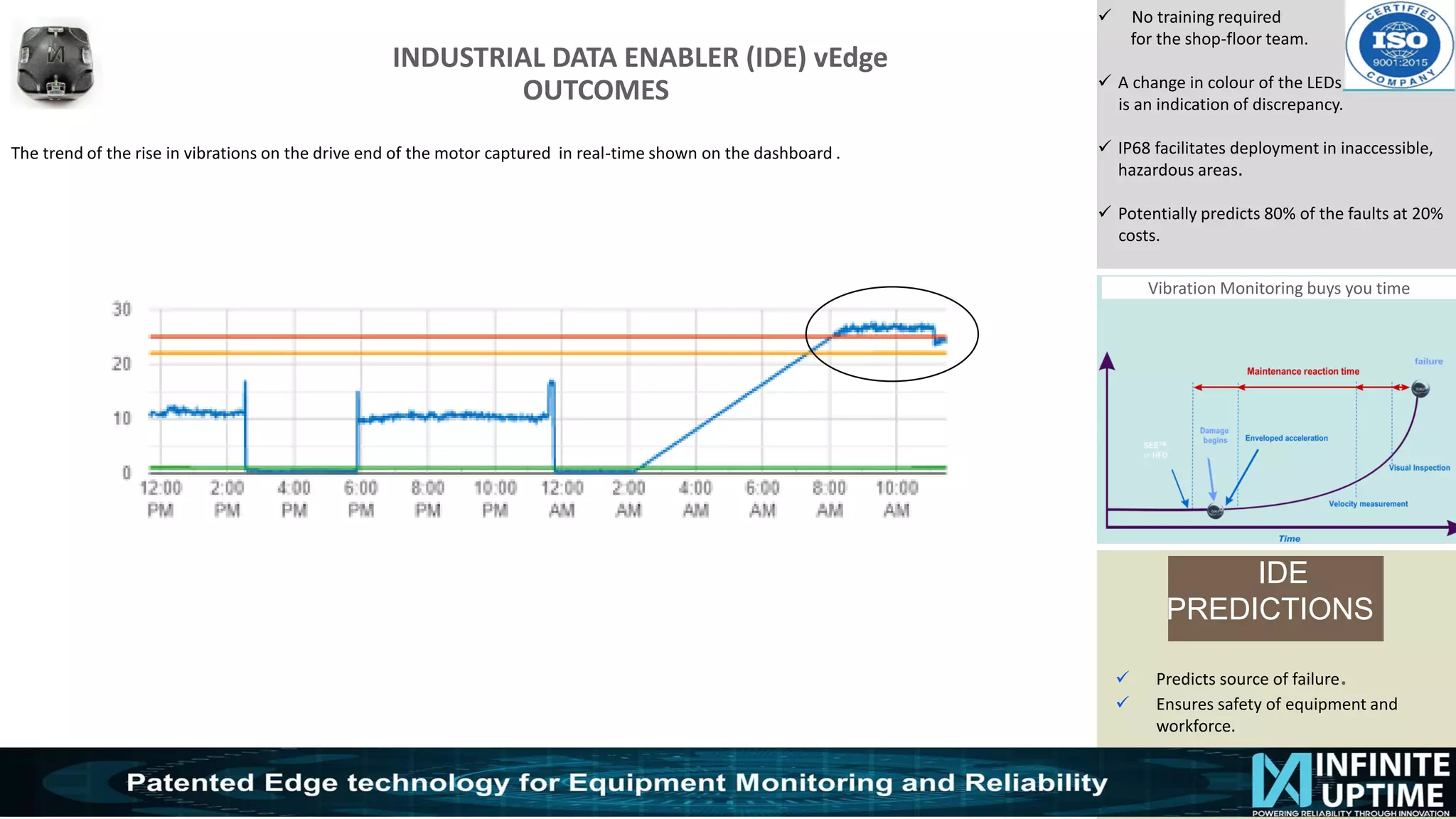

The document details SKF Group's predictive maintenance solutions, highlighting the installation of their Industrial Data Enabler (IDE) to monitor critical equipment such as motors and machines in various manufacturing plants in India. By tracking vibrations, temperature, and other parameters in real-time, the IDE helps in preventing failures, reducing downtime, and ensuring consistent production without compromising operational schedules. The system significantly enhances maintenance efficiency and cost-effectiveness, resulting in considerable savings for the companies involved.