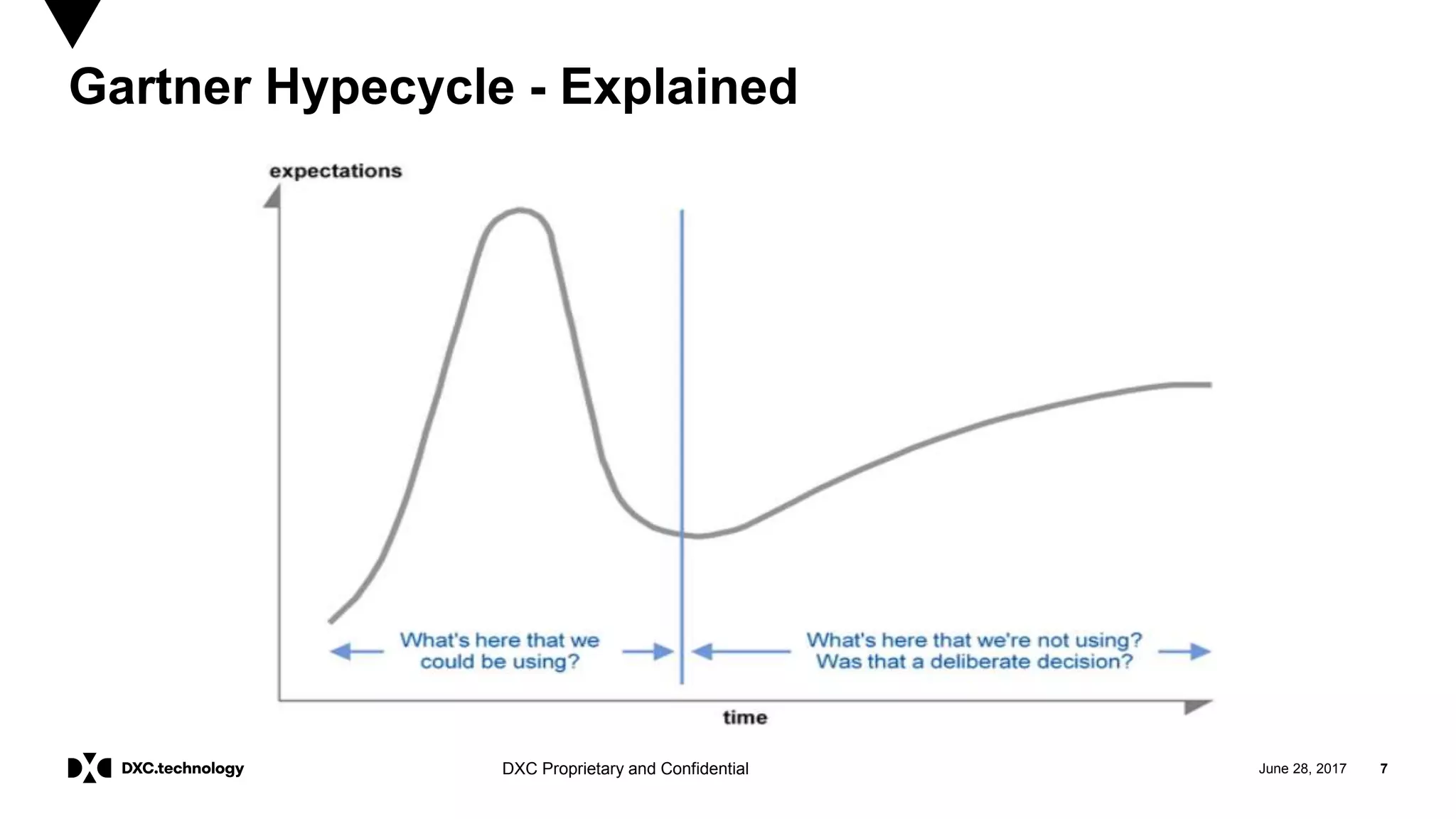

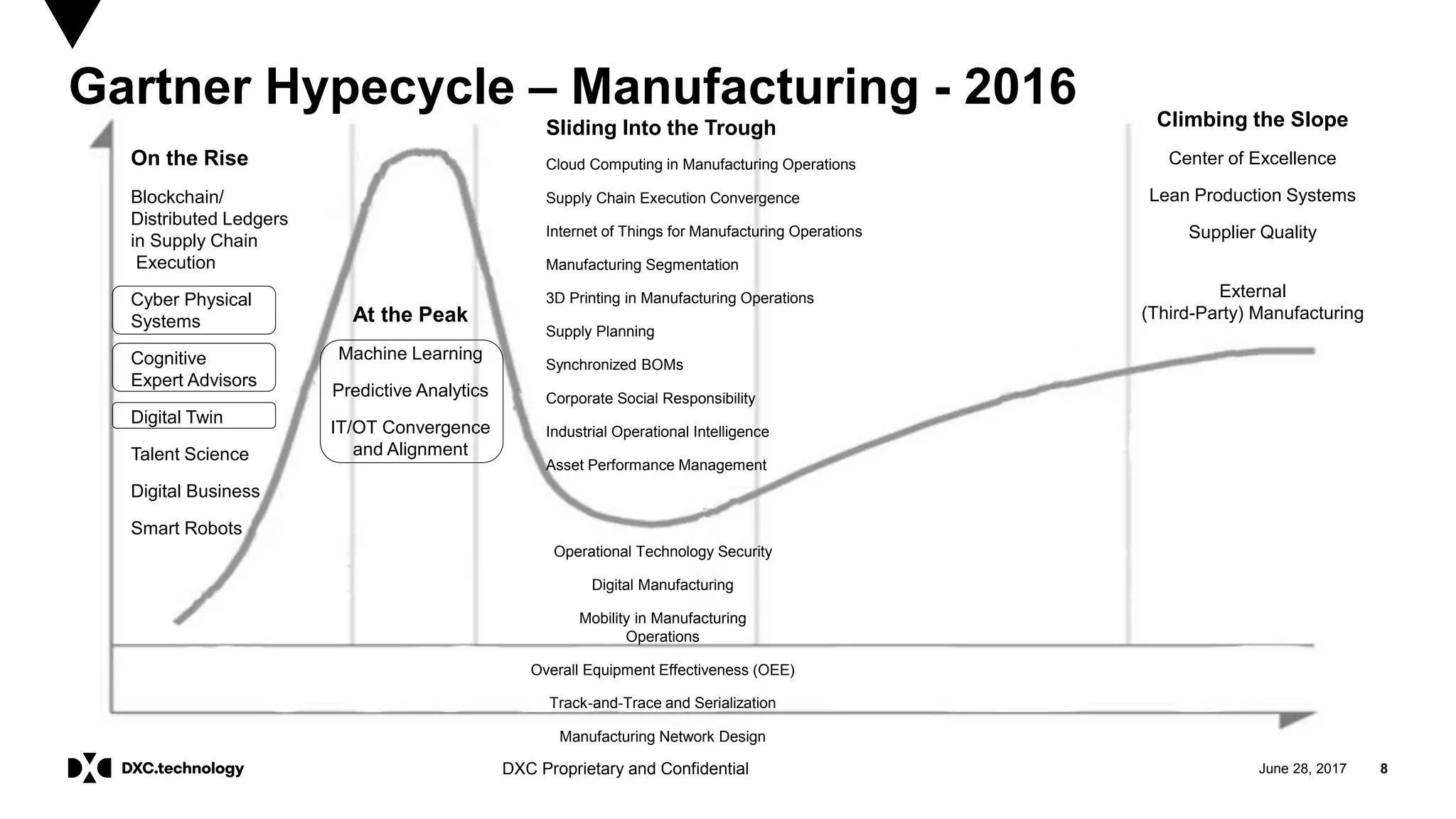

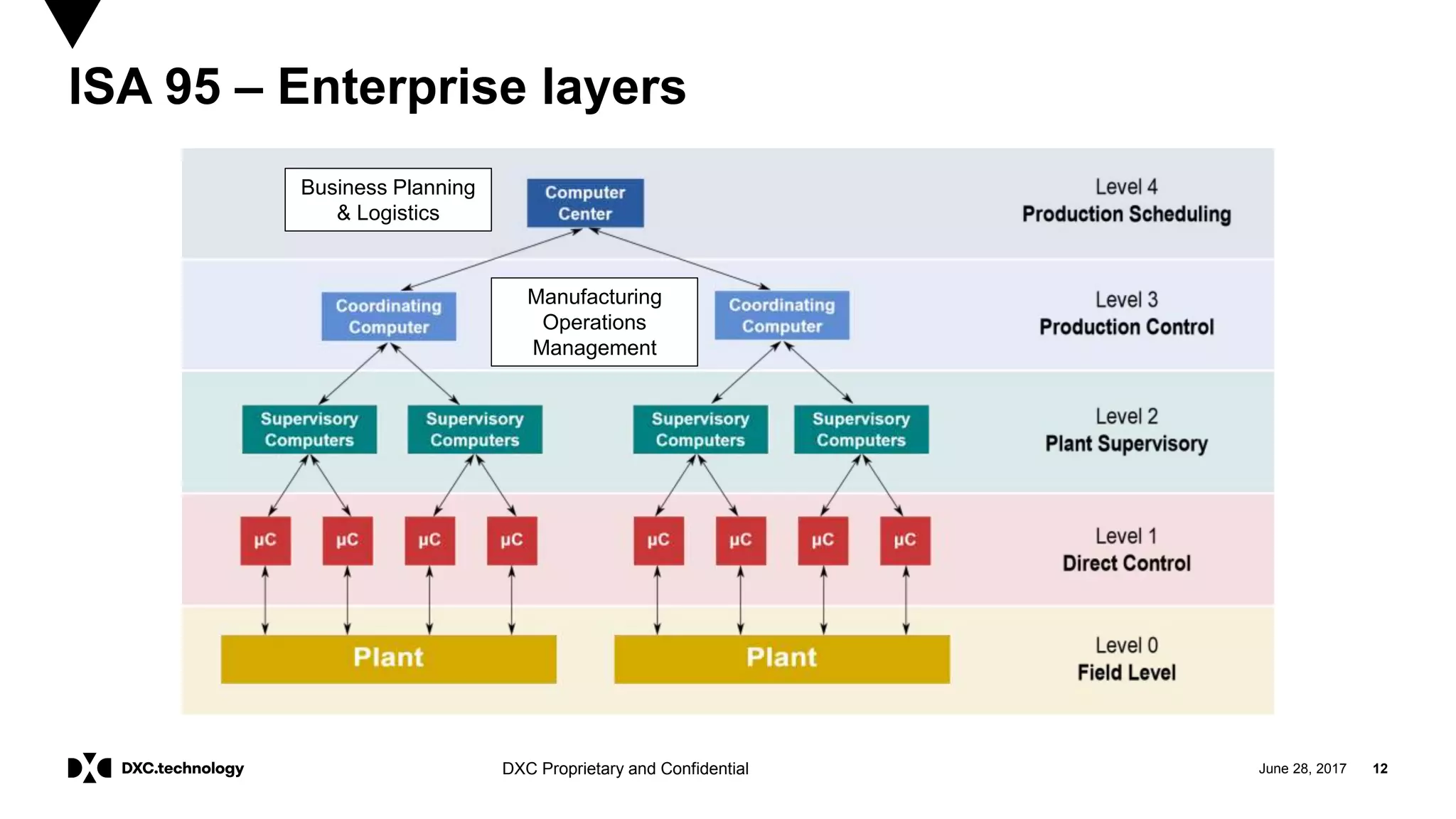

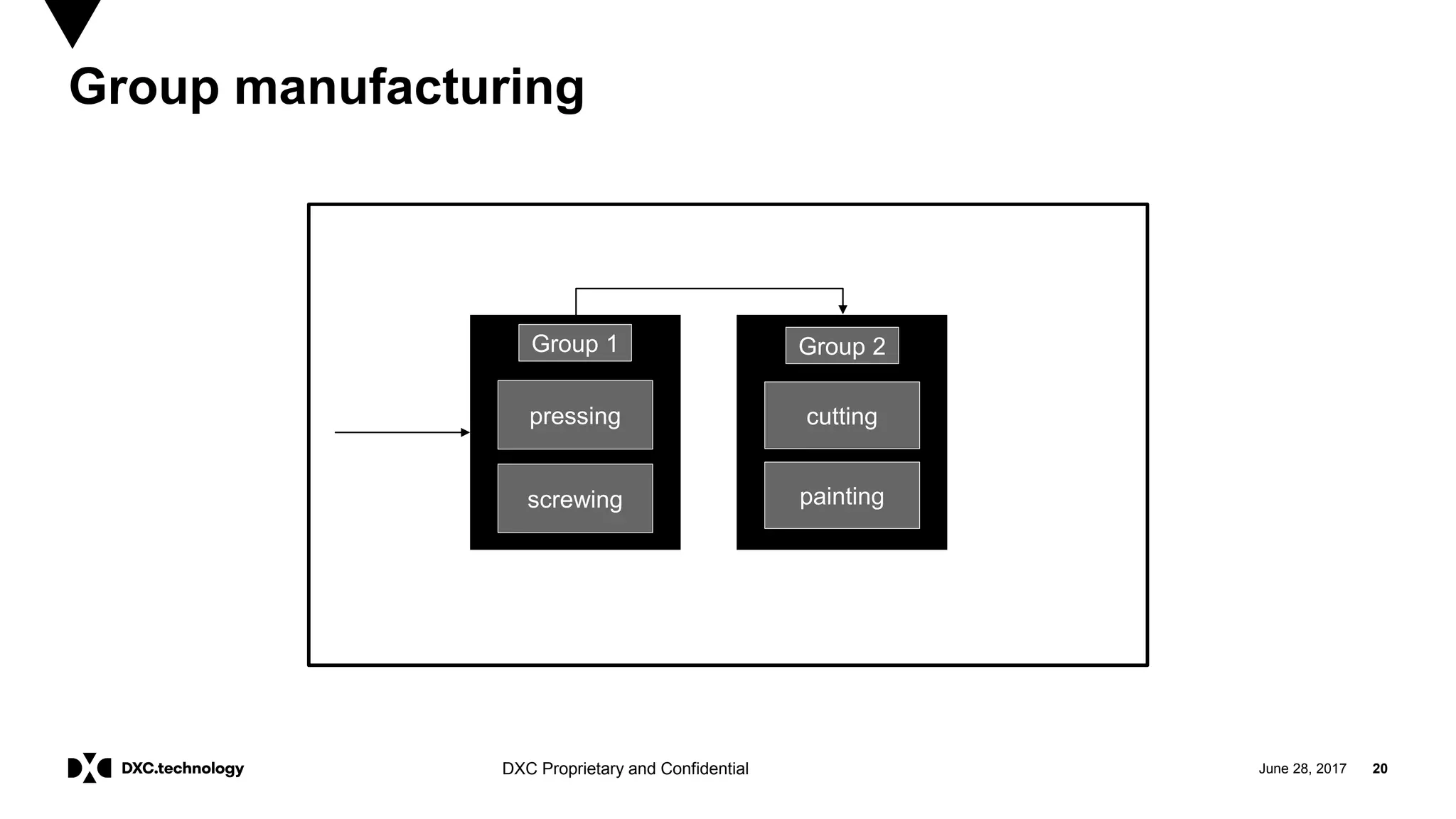

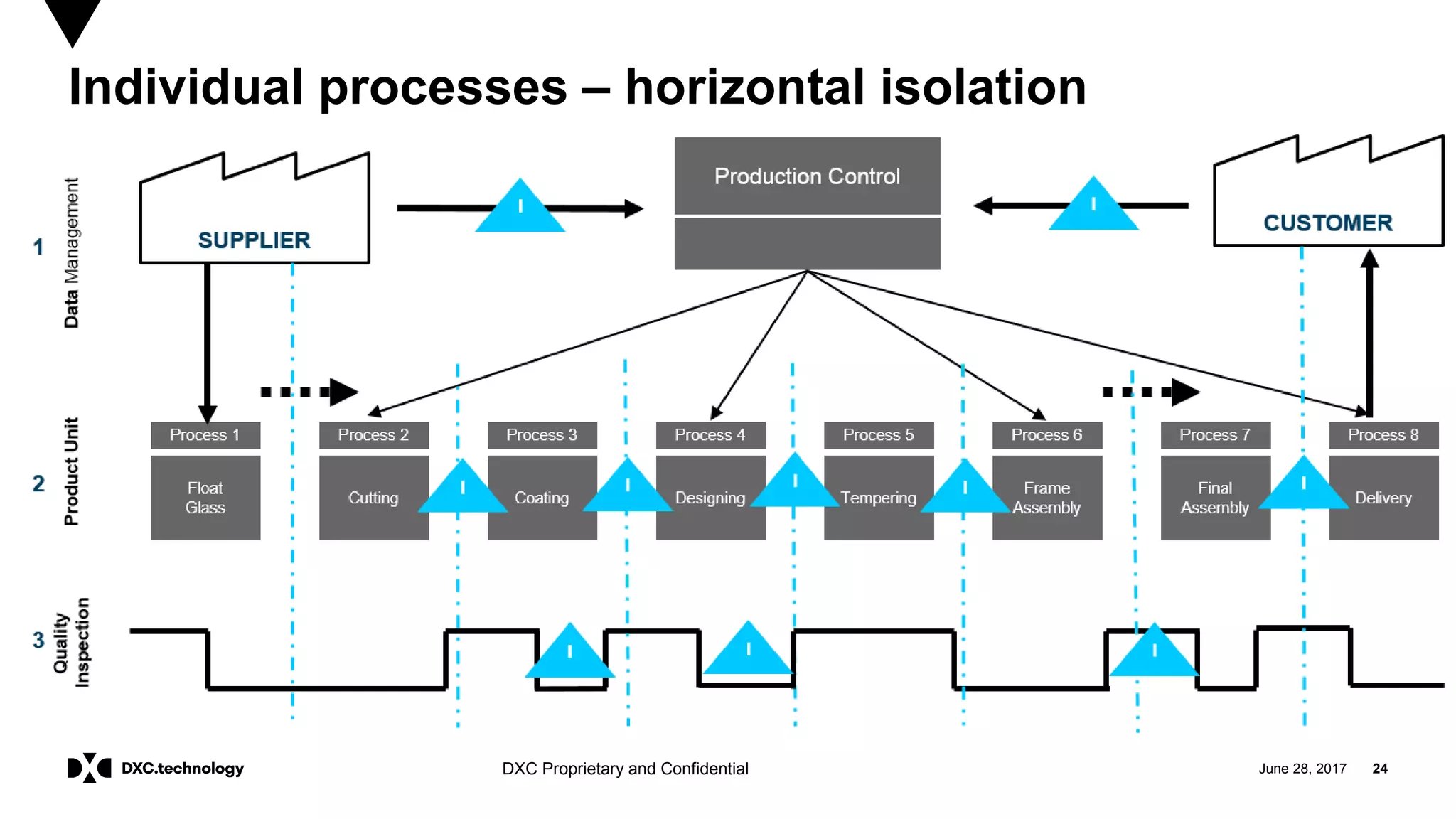

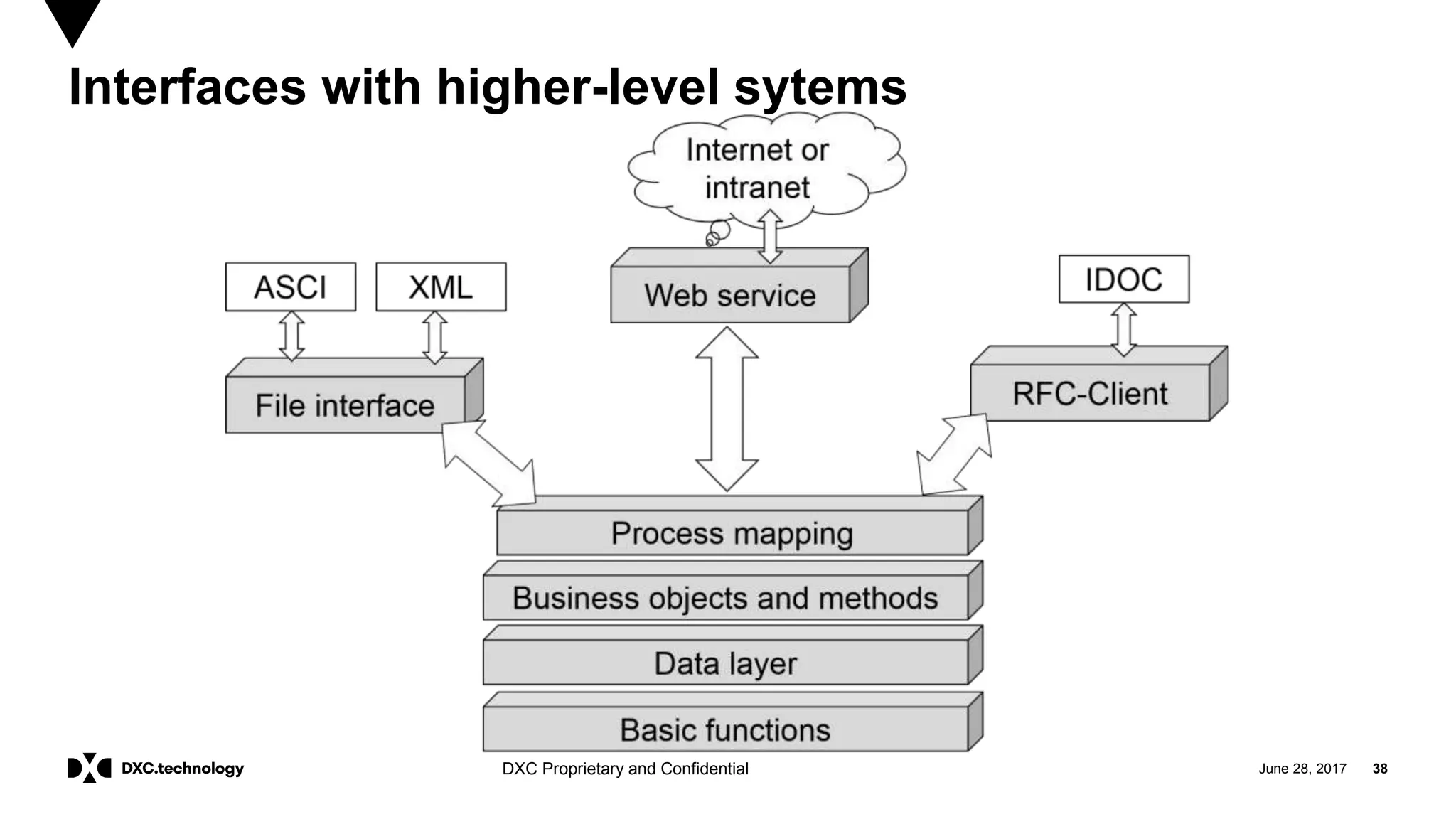

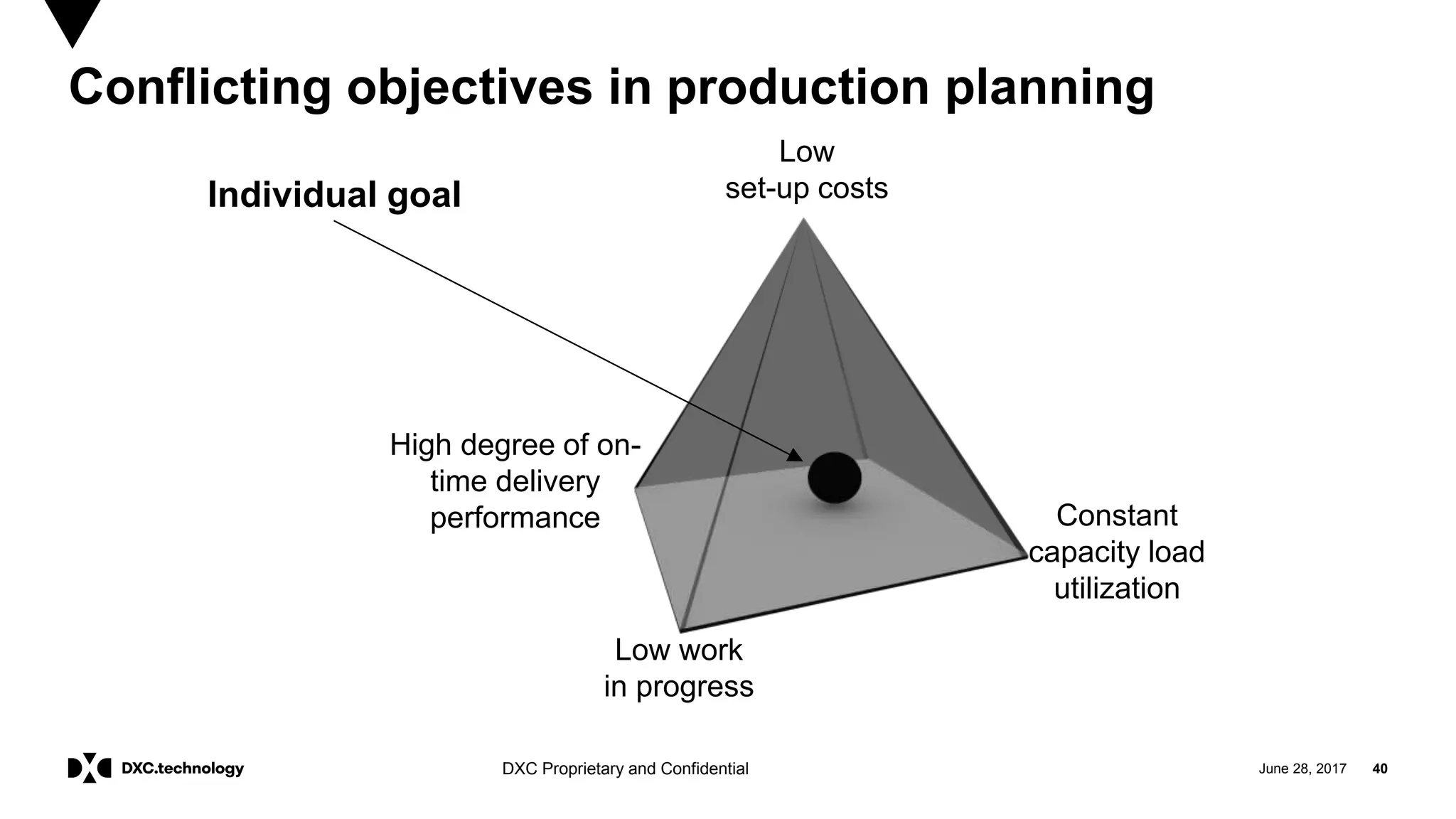

The document discusses smart manufacturing and the integration of technology in production processes, emphasizing digital transformation, innovation, and efficiency improvements. It outlines various strategies for manufacturing industries, including big data processing, advanced robotics, and connected operations. The content also covers the challenges of classical production methods and presents modern solutions such as lean production techniques and the use of digital twins.