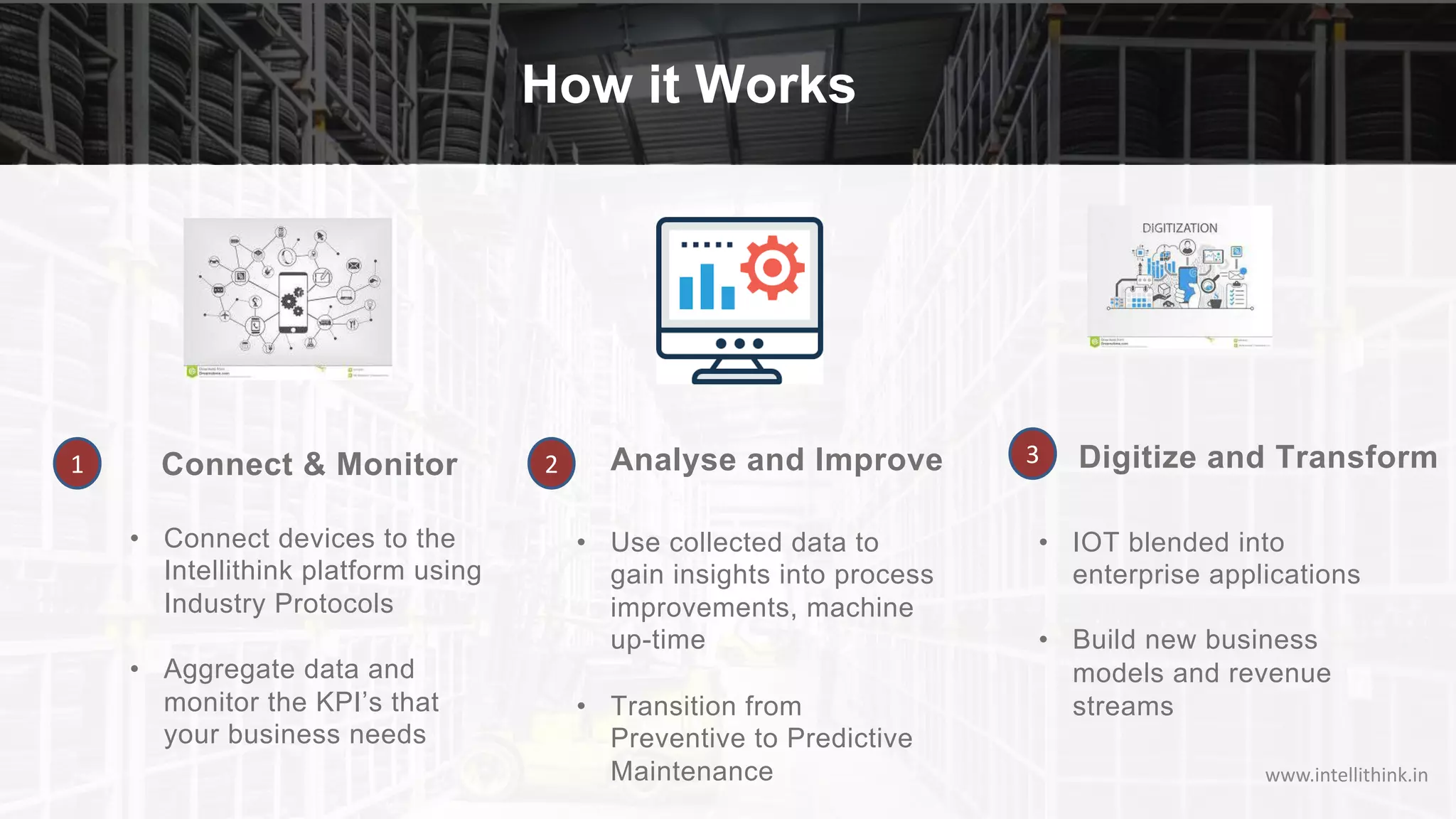

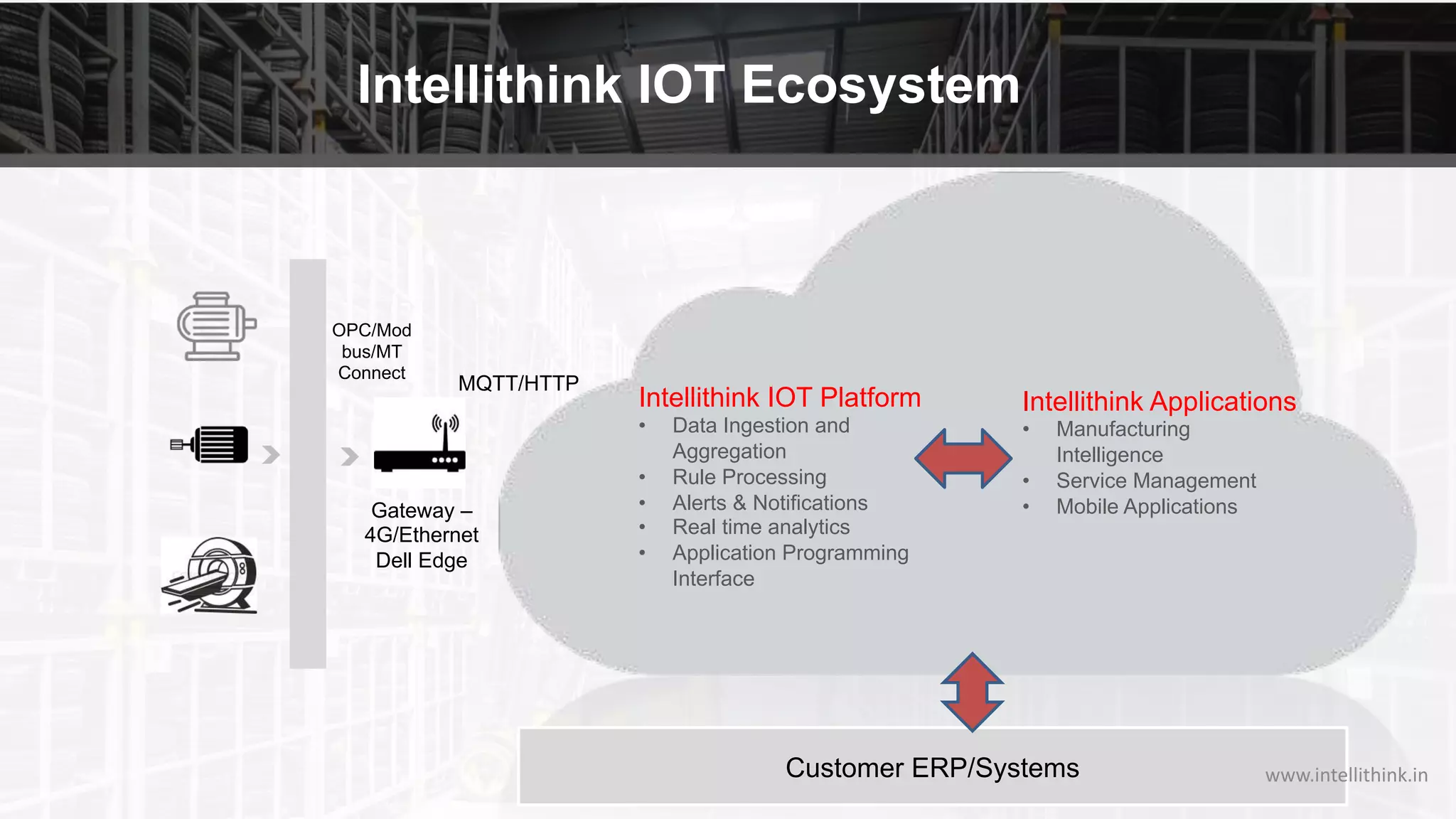

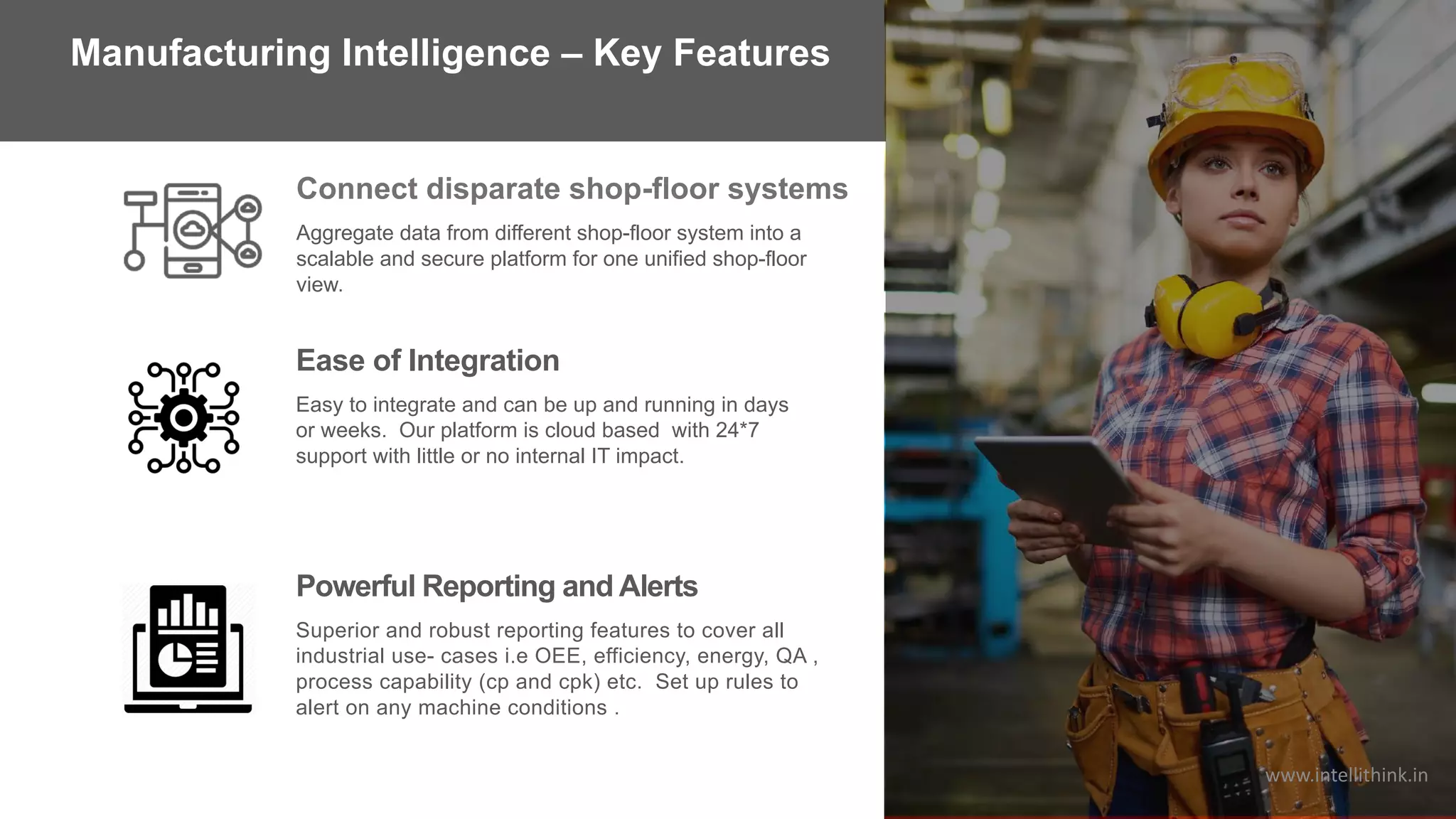

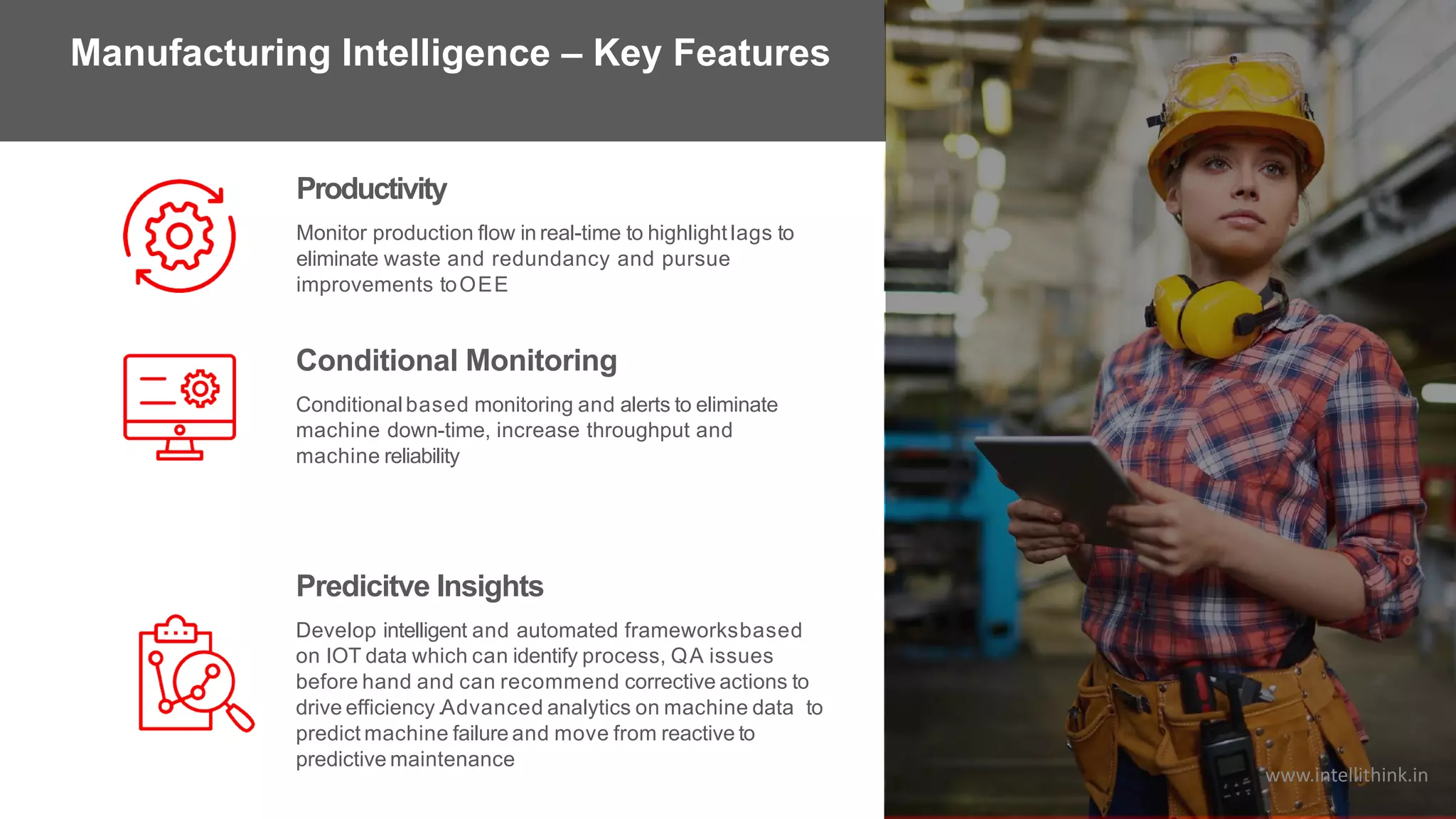

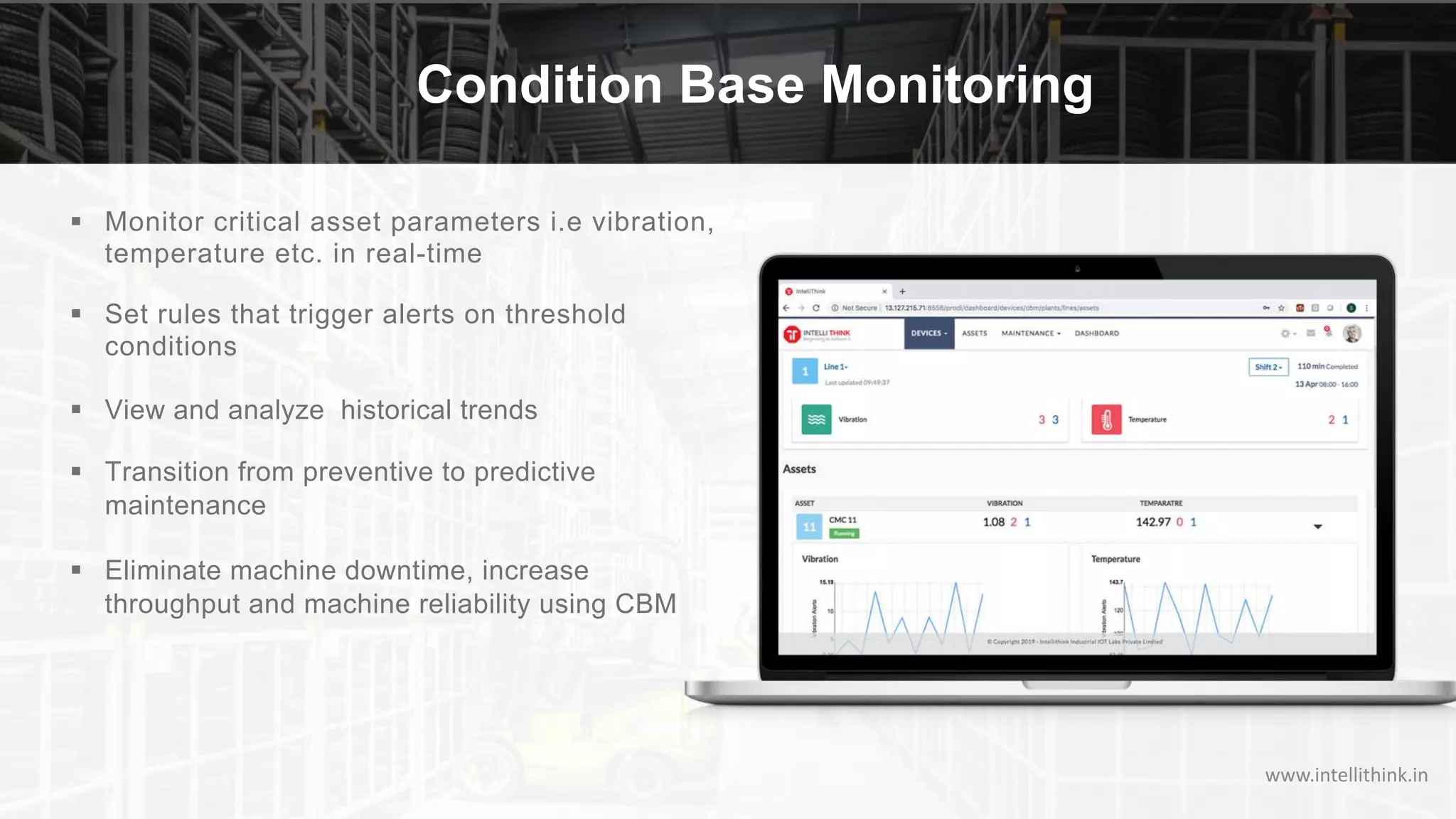

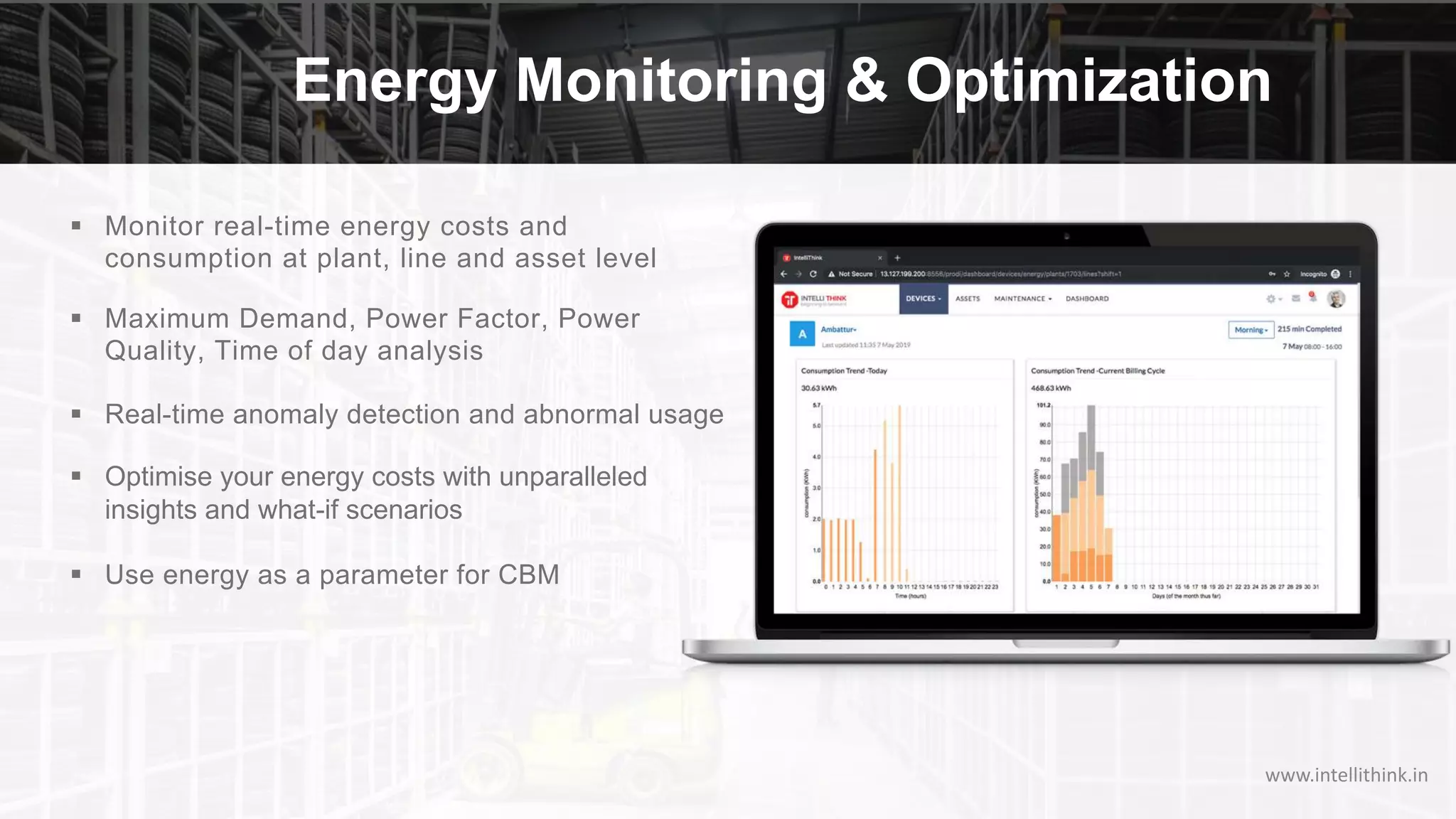

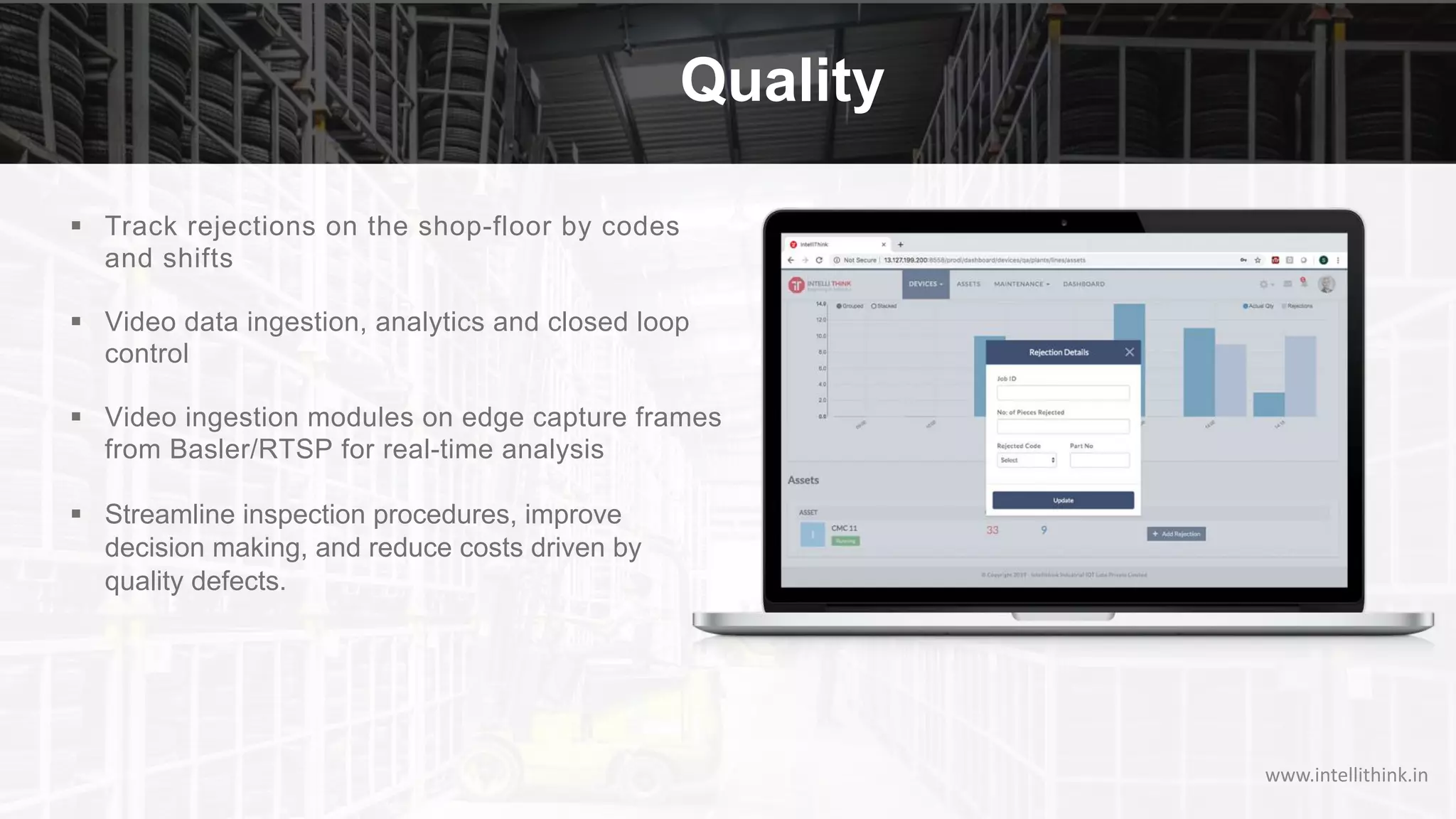

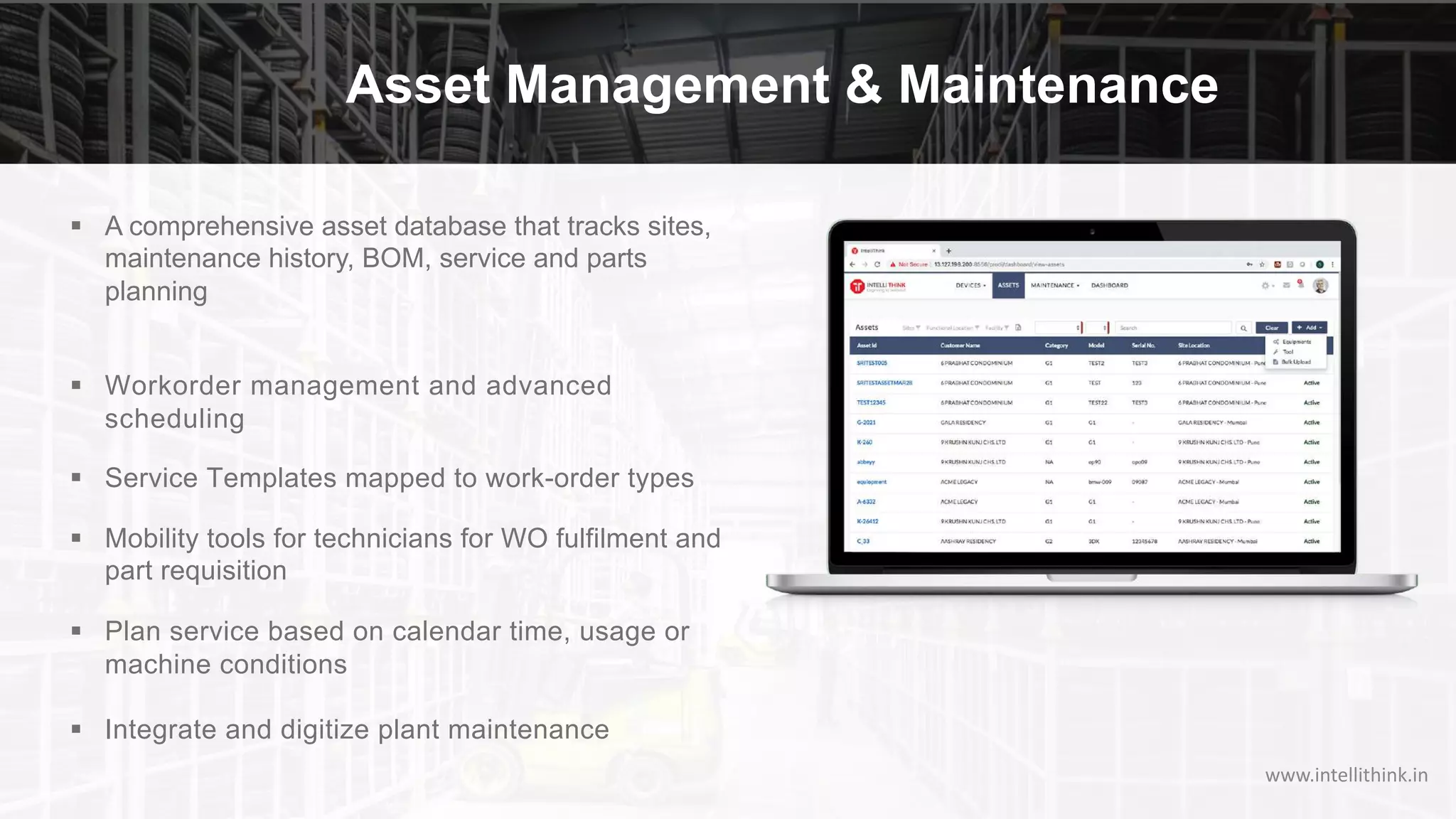

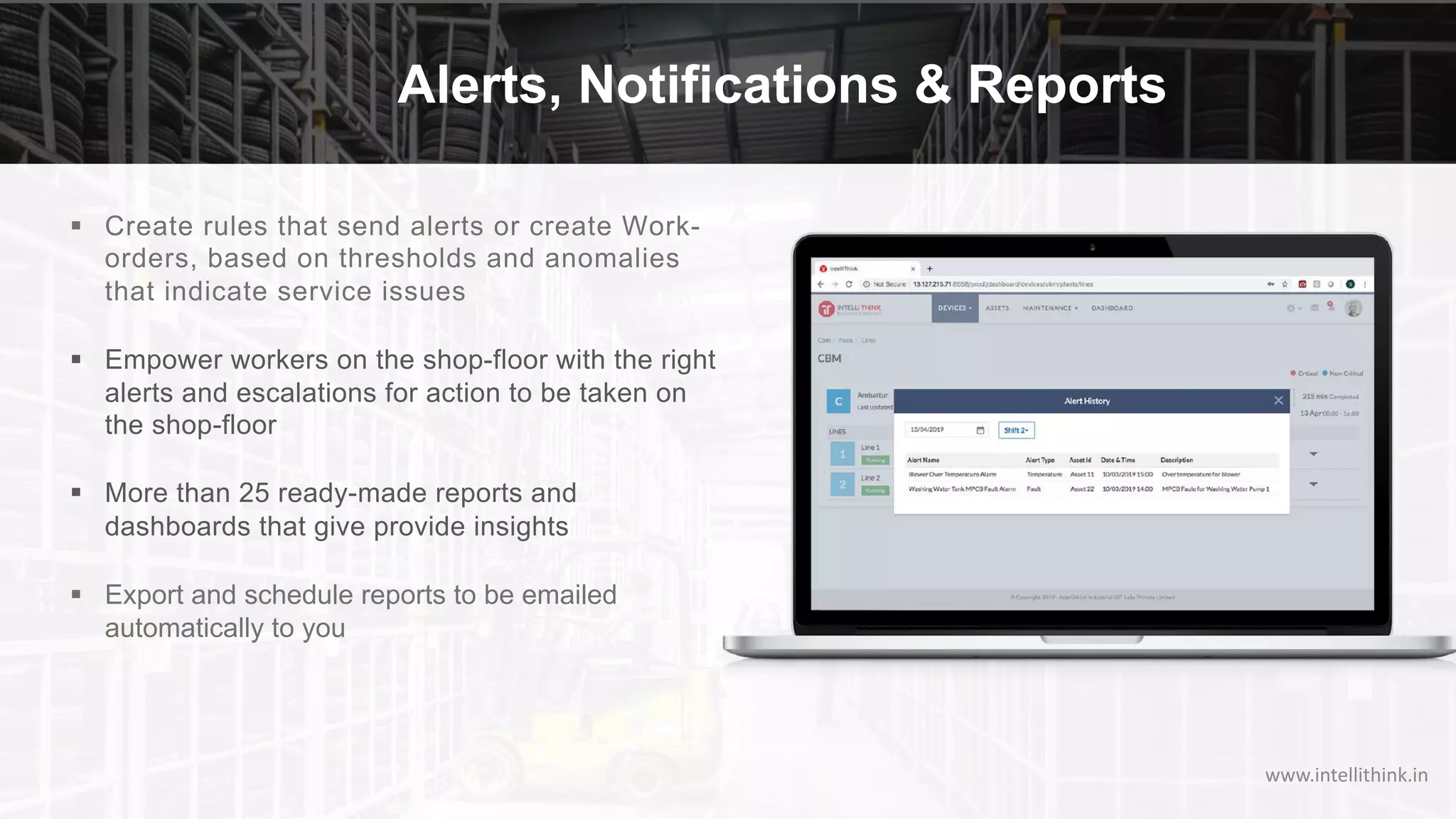

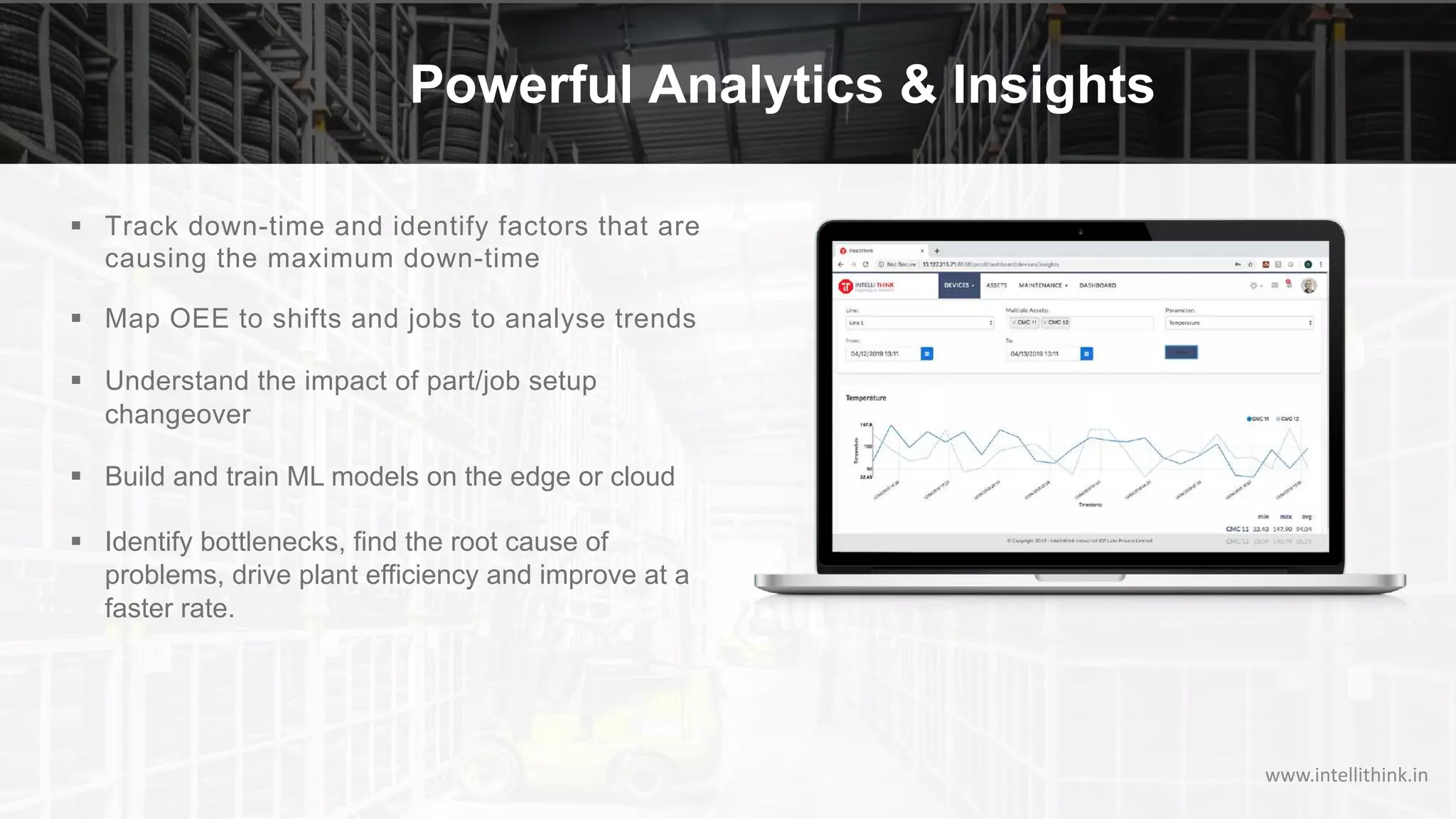

Intellithink provides Industrial IoT solutions aimed at enhancing asset management, maintenance, monitoring, and field service to support customers in their transition to Industry 4.0. Their platform offers real-time visibility into manufacturing processes, predictive analytics, and easy integration with existing systems, enabling improved productivity, worker safety, and operational efficiency. The company also shares case studies demonstrating successful implementations of their technology across various industries, showcasing its potential to reduce downtime and improve overall equipment effectiveness.