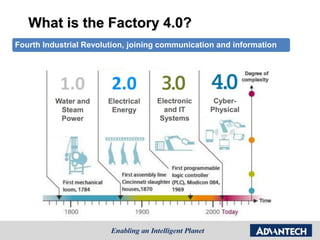

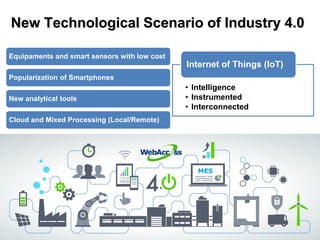

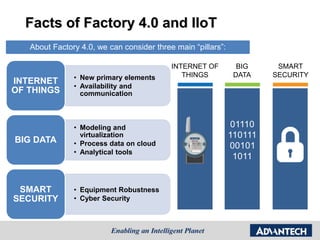

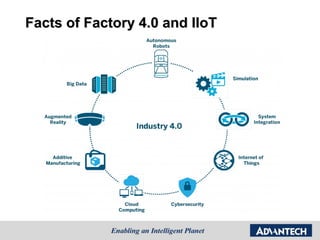

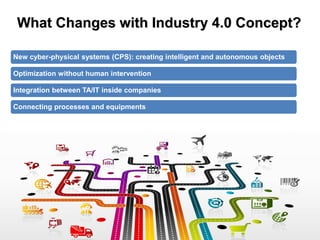

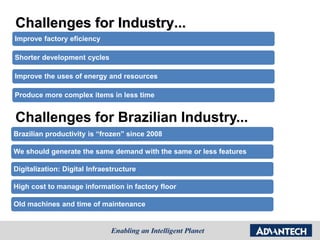

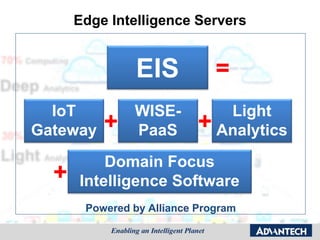

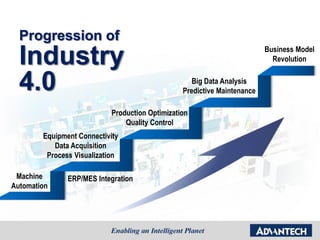

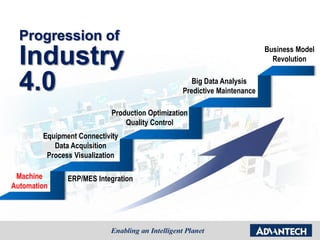

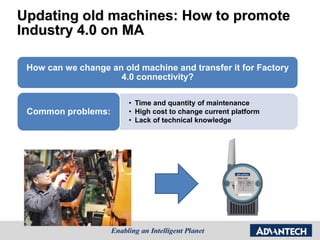

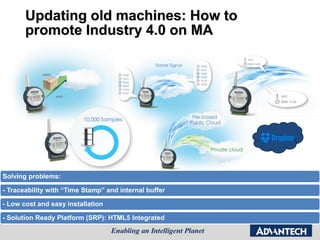

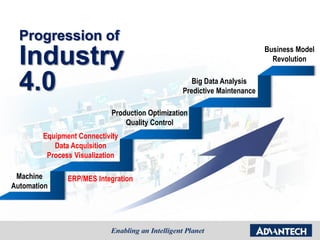

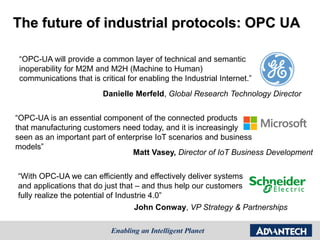

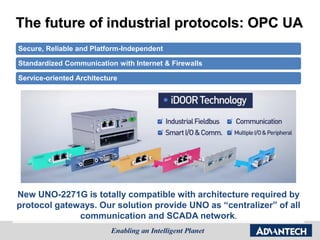

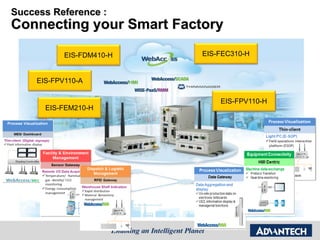

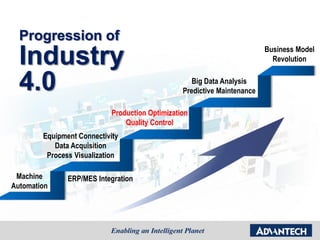

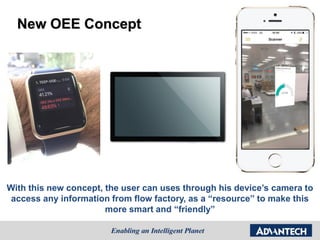

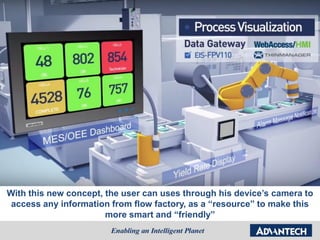

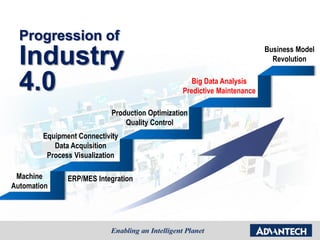

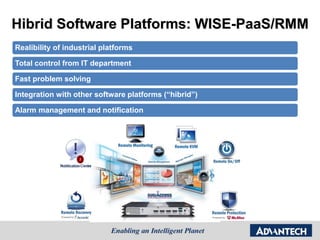

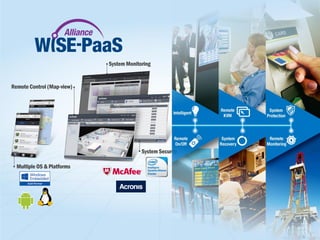

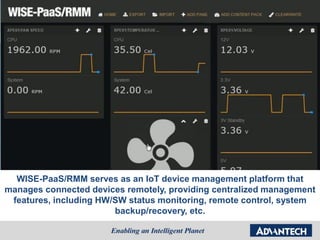

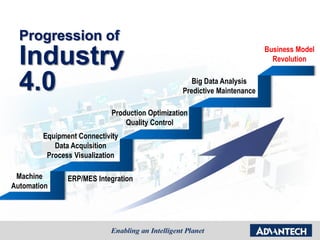

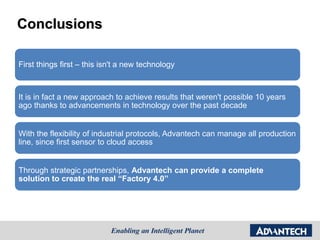

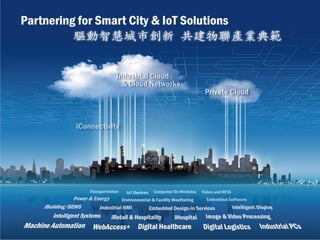

This document discusses Factory 4.0 and the Industrial Internet of Things (IIoT). It outlines the key facts and challenges of Factory 4.0, including new technological capabilities and the need to improve efficiency. Advantech solutions are presented that can help industries address challenges through technologies like augmented reality, edge intelligence servers, hybrid software platforms, and the OPC UA protocol. In conclusions, Factory 4.0 represents a new approach to leverage recent technological advances to achieve improved results.