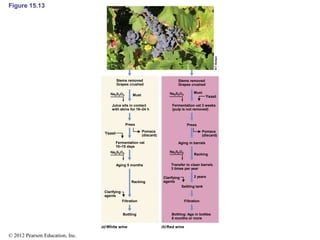

1. Industrial microbiology uses microorganisms grown on a large scale to produce useful products through fermentation or other chemical transformations. It originated with alcoholic fermentation and now produces pharmaceuticals, food additives, enzymes, and chemicals.

2. Useful industrial microbes are those that produce the desired product quickly and efficiently without being pathogenic. They must also be amenable to genetic manipulation.

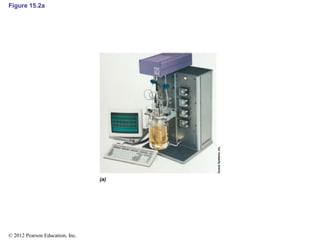

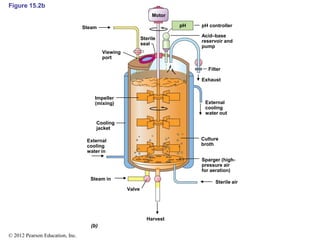

3. Microbial products produced industrially include cells, enzymes, antibiotics, food additives, and commodity chemicals. Large scale fermentation uses fermentors to grow the microbes under controlled conditions.

![15.5 Vitamins and Amino Acids

• Amino acids

– Used as feed additives in the food industry

– Used as nutritional supplements in

nutraceutical industry

– Used as starting materials in the chemical

industry

– Examples include

• Glutamic acid (MSG)

• Aspartic acid and phenylalanine (aspartame

[NutraSweet])

• Lysine (food additives; Figure 15.9)

© 2012 Pearson Education, Inc.](https://image.slidesharecdn.com/industrialmicro-240129135957-01f6e2d8/85/industrialmicro-ppt-21-320.jpg)