This study investigated the impact resistance of fibre reinforced concrete plates through a drop weight test. Concrete plates were made with two fibre types - polypropylene and hooked steel fibres - at different volume fractions. Test results found that both fibre types improved the impact resistance of plates compared to plain concrete, with steel fibres being more effective. Plates with a hybrid of steel and polypropylene fibres performed best, requiring higher impact energy to cause failure. The hybrid fibre plates showed a ductile failure pattern and were able to absorb more impact energy than plates with individual fibre types.

![International Journal of Mechanical, Civil, Automobile and Structural Engineering (IJMCAS)

Vol. 1, Issue. 1, April – 2015 ISSN (Online): 2395-6755

13

Abstract— In this study, an experimental investigation on the

impact resistance of fibre reinforced concrete (FRC) plates is

done by us using a simple drop weight test. The testing procedure

was recommended by ACI committee 544. For this purpose

concrete plates were prepared at the size of 50cm x 50cm x 5cm.

Two different fibres were used in this investigation such as

polypropylene, hooked end steel fibre with the volume fraction of

0.2% and 0.4% for Polypropylene and 0.5% and 1.0% for Steel

Fibre. The results indicated the addition of polypropylene and

steel fibre into the concrete can enhance the impact strength of

the concrete plates. Further, the steel fibres were efficient in

arresting the cracks and polypropylene fibres in arresting the

micro cracks. The specimen with 0.9% steel + 0.1%

polypropylene hybrid concrete developed excellent impact

energy which was so many times higher than the plain concrete.

Keywords— Impact energy, Drop weight Test, Number of blows

I. INTRODUCTION

Brittleness of normal and high strength concrete increases

with the increasing strength and it is considered as

disadvantage, since it severely affects the performance of

concrete especially under impact loads. In order to overcome

this problem several research have been carried out to enhance

the properties of normal and high strength concrete such as

durability, ductility, flexural strength, fracture toughness,

thermal and shock strength, resistance under dynamic, fatigue

and impact load by inclusion of various type of fibres in

concrete mixture [1-6]. The impact resistance of concrete can

be determined by various test methods such as the explosive

test, dropweight test and projectile impact test; suggested by

different guidelines [7-10]. Alavi Nia et al. [11] developed a

numerical simulation by examining the effect of different

volume fractions of hooked end steel and polypropylene fibre

on the impact strength. There are many studies about the

influence of hybrid fibres on the fresh and hardened properties

of normal concrete [12-15]

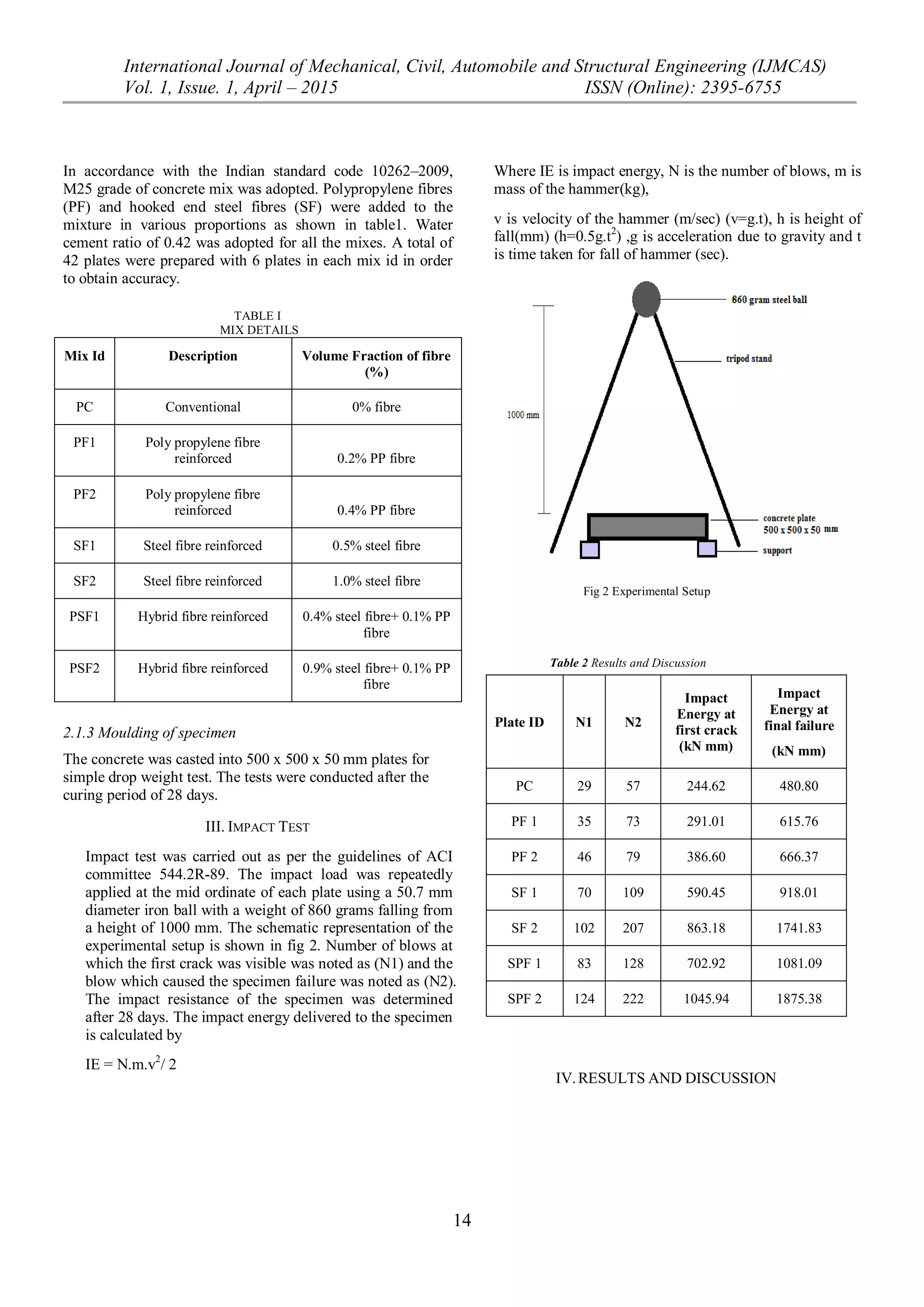

II. EXPERIMENTAL WORK

The main objective of our experimental work is to find out the

impact resistance of the steel, polypropylene and hybrid fibre

reinforced plates.

2.1 Materials

2.1.1 Cement, fine aggregate and coarse aggregate

The Ordinary Portland Cement of 53 grade was used for all

the mixes and the specific gravity of the cement was 3.15.

Siliceous river sand passed through 4.75 mm IS sieve was

used as the fine aggregate with specific gravity of 2.61.The

hard broken stone passing through 20 mm IS sieve and retain

on 12.5 mm IS sieve was used as the coarse aggregate with

the specify gravity of the 2.70.

2.1.2. Fibre

The hybrid fibres used in this study are shown in figure 1.

(a) Hooked end steel fibres of length 30mm and

diameter 0.5mm with Aspect ratio of 60 (b)

Fibrillated multidimensional Poly propylene fibres of

length 10-12mm.The specific gravity and tensile

strength of steel fibres(SF) are 7.9 and 1100 Mpa and

polypropylene fibres (PF) are 0.91 and 550 Mpa

respectively.

Fig 1. Steel and Polypropylene fibre

2.1.2 Water and Mixing

Impact Resistance of Hybrid Fibre-reinforced concrete

Plates

1

G.Murali, 2

Prithvi Elango

1,2

Department of Civil Engineering, Panimalar Engineering College, Chennai, INDIA](https://image.slidesharecdn.com/iisrtprithvielangocivil-150705080757-lva1-app6892/75/Iisrt-prithvi-elango-civil-1-2048.jpg)

![International Journal of Mechanical, Civil, Automobile and Structural Engineering (IJMCAS)

Vol. 1, Issue. 1, April – 2015 ISSN (Online): 2395-6755

15

It can be seen from the figure 3, the mixes PF1, PF2, SF1 and

SF2 showed an increase in no of blows to first crack by 1.19,

1.58, 2.41 and 3.52 times compared to PC. Whereas the

hybrid fibre reinforced plates SPF1 and SPF2 showed an

increase of 2.87 and 4.28 times strength comparing to the

plain concrete plates. Similarly the mix PF1, PF2, SF1, SF2,

SPF1, SPF2 showed increase in number of cracks to failure by

1.28, 1.38, 1.90, 3.62, 2.24 and 3.90 times strength

respectively.

Comparing to the PC, the impact energy at first crack was

increasing 18.96%, 58.04%, 141.37%, 252.87%, 187.35%,

327.56% for PF1, PF2,SF1, SF2 SPF1and SPF2 respectively.

The hybrid fibre reinforced plates showed high performance,

thus required higher energy to break.

The increase in impact failure energy at failure was observed

by 28.07%, 38.59%, 90.93%, and 262.87% for PF1, PF2, SF1,

and SF2 respectively. Further it showed 124. 85%, 290.05%

increment in the SPF1, SPF2 respectively. From the results it

is evident that the addition of fibres increase the impact

resistance.The Impact failure energy values of concrete,

increased in the cases, PF, SF and SPF when compared to PC

and this increase in energy is slightly greater in case of SPF

when compared to SF and PF. Furthermore, it can be

concluded that the addition of steel fibre to concrete

significantly increases its impact resistance.

Fig 3. Impact energy versus mix id

V. CRACK PATTERN

The crack pattern for different proportions of fibre added is

shown in fig 4. The plate in which 0% fibres were added

brittle mode of failure was observed and it was broken into

two pieces. Adding the fibre to concrete lead to encounter

the ductile mode of failure and bridging the number of cracks

which displays the beneficial effects of adding fibre to

concrete.

Fig 4. Crack pattern of fibre reinforced plates of different proportions.

VI.CONCLUSIONS

The performance of fibre concrete plate under impact loads

was very positive especially in hybrid fibre reinforced

concrete including polypropylene and steel fibre. But hybrid

fibre was the more effective than polypropylene and steel

fibre. Under impact loading, a ductile failure was observed in

non fibrous concrete. The failure pattern of plate shows that

incorporation of polypropylene, steel and hybrid fibre as an

arrestor of crack propagation considerably improves the

ability of concrete to absorb kinetic energy.

REFERENCES

[1] Nataraja, M. C., Dhang, N. and Gupta, A., ―Statistical Variations in

Impact Resistance of Steel Fibre-Reinforced Concrete Subjected to Drop

Weight Test,‖ Cement and Concrete Research, Vol. 29, No. 7, pp. 989_ 995

(1999).

[2] Nataraja, M. C., Nagaraj, T. S. and Basavaraja, S. B., ―Reproportioning of

Steel Fibre Reinforced Concrete Mixes and their Impact Resistance,‖ Cement

and Concrete Research, Vol. 35, pp. 2350_2359 (2005).

[3] Lu, X. and Hsu, C., ―Behavior of High Strength Concrete with and

without Steel Fibre Reinforcement in Triaxial Compression,‖ Cement and

Concrete Research, Vol. 36, pp. 1679_1685 (2006).

[4] Taner Yildirim, S., Cevdet, E. and Fehim Findik, E., ―Properties of Hybrid

Fibre Reinforced Concrete under

Repeated Impact Loads,‖ Russian Journal of Nondestructive Testing, Vol. 46,

No. 7, pp. 538_546 (2010).

[5] Mohammadi, Y., Carkon-Azad, R., Singh, S. P. and Kaushik, S. K.,

―Impact Resistance of Steel Fibrous

Concrete Containing Fibres of Mixed Aspect Ratio,‖ Construction and

Building Materials, Vol. 23, pp. 183_189 (2009).

[6] Chen X. Y., Ding, Y. N. and Azevedo, C., ―Combined Effect of Steel

Fibres and Steel Rebars on Impact Resistance of High Performance

Concrete,‖ J Cent South Univ Technol, Vol. 18, pp. 1677_1684 (2011).

[7] Song, P.,Wu, J., Hwang, S. and Sheu, B., ―Assessment of Statistical

Variations in Impact Resistance of High- Strength Steel Fibre-Reinforced

Concrete,‖ Cement and Concrete Research, Vol. 35, No. 2, pp. 393_399

(2005).

[8] Atef, B., Ashraf, F. and Andrew, K., ―Statistical Variations in Impact

Resistance of Polypropylene Fibre-Reinforced Concrete,‖ International

Journal of Impact Engineering, Vol. 32, pp. 1907_1920 (2006).](https://image.slidesharecdn.com/iisrtprithvielangocivil-150705080757-lva1-app6892/75/Iisrt-prithvi-elango-civil-3-2048.jpg)

![International Journal of Mechanical, Civil, Automobile and Structural Engineering (IJMCAS)

Vol. 1, Issue. 1, April – 2015 ISSN (Online): 2395-6755

16

[9] G. Murali, A. S. Santhi and G. Mohan Ganesh, ―Effect of Crimped and

Hooked End Steel Fibres on the Impact Resistance of Concrete‖ Journal of

Applied Science and Engineering, Vol. 17, No. 3, pp. 259_266 (2014)

[10] G. Murali, A. S. Santhi and G. Mohan Ganesh, ―Empirical Relationship

between the Impact Energy and Compressive Strength for Fibre Reinforced

Concrete‖ Journal of Scientific & Industrial Research ,Vol. 73, July 2014, pp.

469-473

[11] Alavi Nia, A., Hedayatian, M., Nili, M. and Afrough Sabet, V., ―An

Experimental and Numerical Study on How Steel and Polypropylene Fibres

Affect the Impact Resistance in Fibre-Reinforced Concrete,‖ International

Journal of Impact Engineering, Vol. 46, pp. 62_73 (2012).

[12] Ahmed SFU, Maalej M, Paramasivam P. Flexural responses of hybrid

steel polyethylene fibre reinforced cement composites containing high volume

fly ash. Constr Build Mater 2007;21(5):1088–97.

[13] Banthia N, Gupta R. Hybrid fibre reinforced concrete (HyFRC): fibre

synergy in high strength matrices. Mater Struct 2004;37(10):707–16.

[14] Banthia N, Nandakumar N. Crack growth resistance of hybrid fibre

reinforced cement composites. Cem. Concr. Compos. 2003;25(1):3–9.

[15] Lawler JS, Wilhelm T, Zampini D, Shah SP. Fracture process of hybrid

fibre reinforced mortar. Mater Struct 2003;35(3):197–208](https://image.slidesharecdn.com/iisrtprithvielangocivil-150705080757-lva1-app6892/75/Iisrt-prithvi-elango-civil-4-2048.jpg)