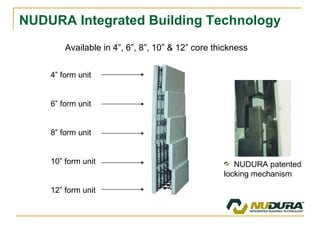

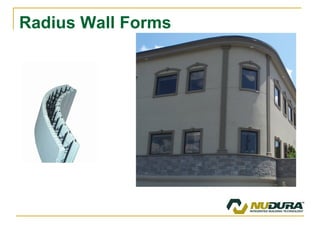

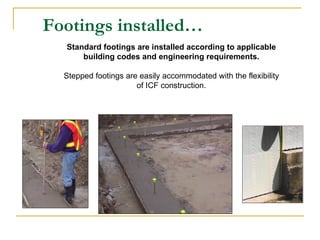

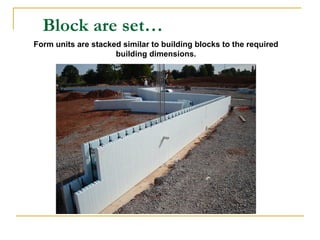

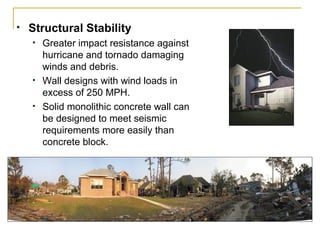

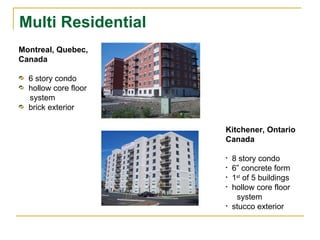

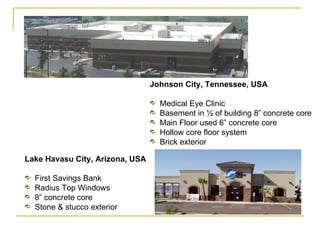

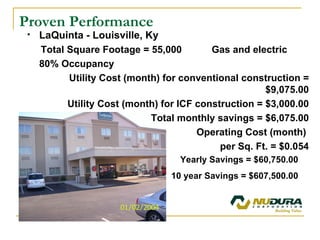

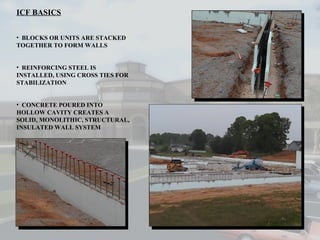

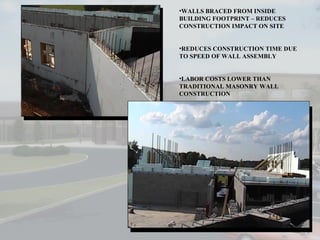

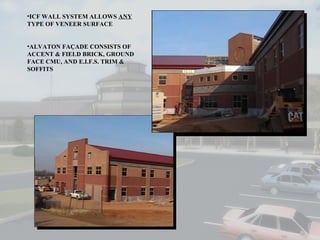

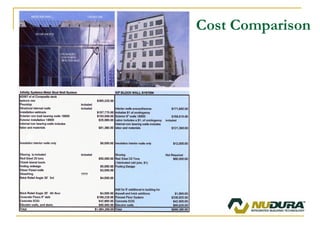

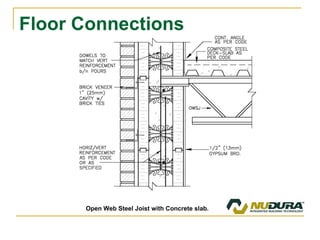

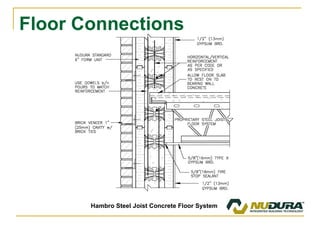

This document provides an overview of insulated concrete form (ICF) building technology using Nudura products. It describes the key benefits of ICF construction including energy efficiency, structural stability, sound resistance, speed of construction, and labor savings. It provides details on Nudura's ICF blocks, installation process, code approvals, applications in multi-residential and commercial buildings, and case studies demonstrating cost and energy savings compared to traditional construction.