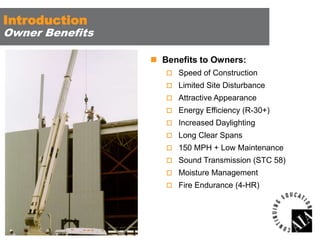

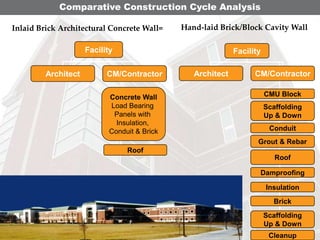

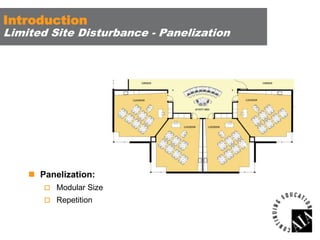

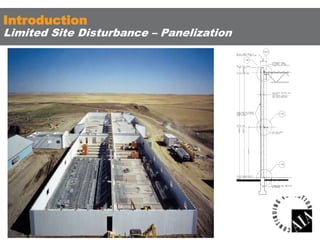

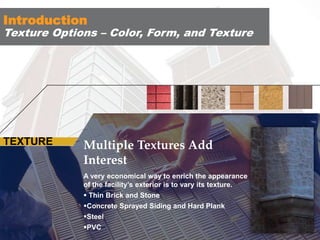

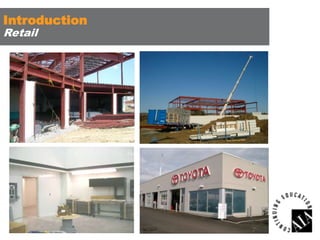

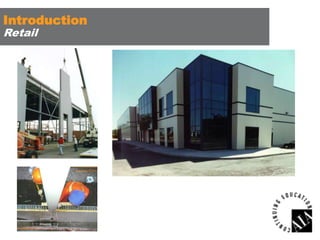

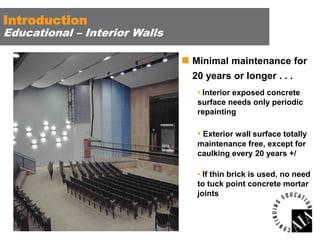

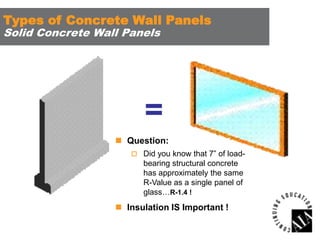

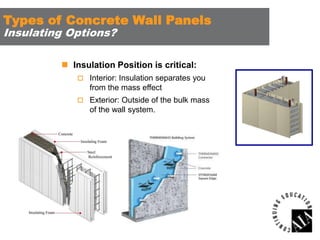

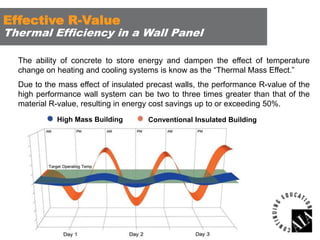

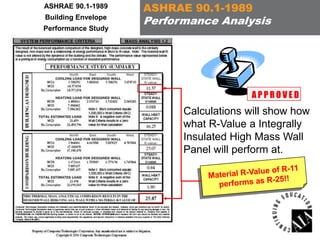

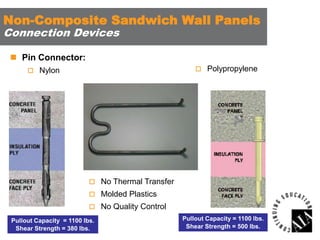

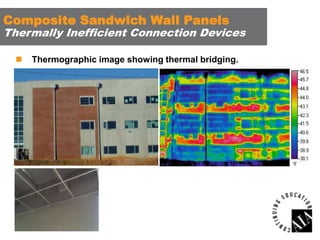

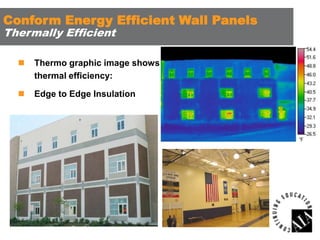

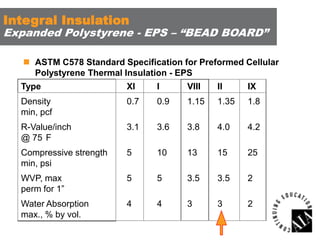

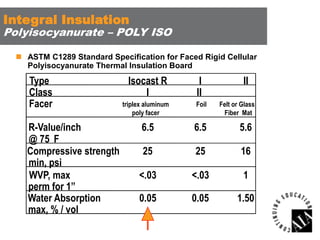

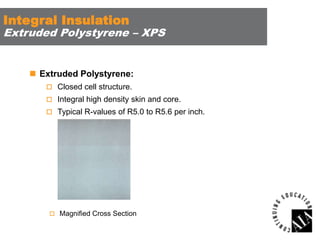

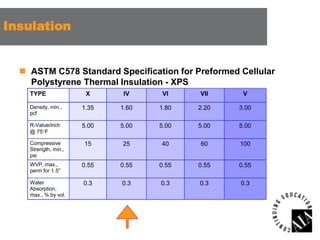

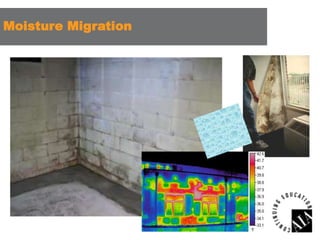

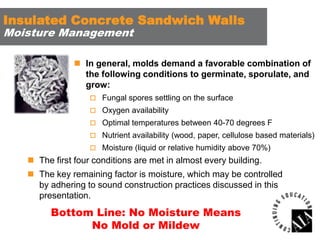

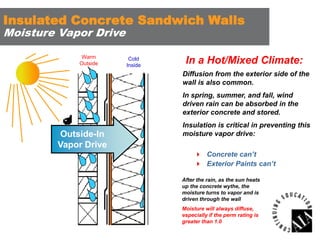

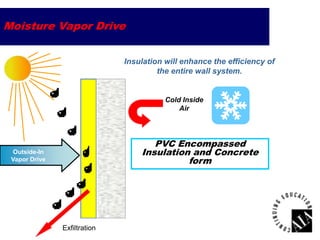

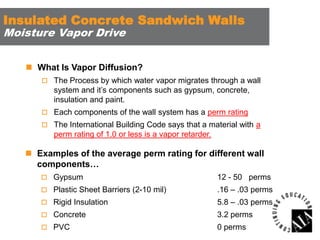

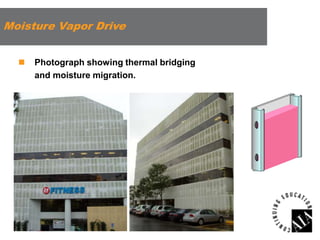

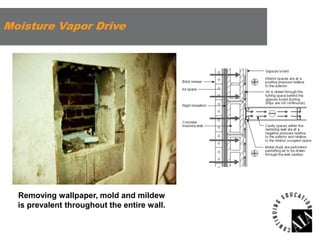

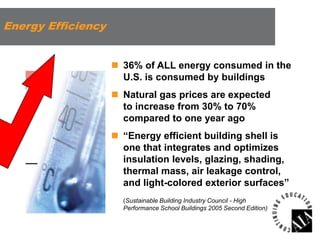

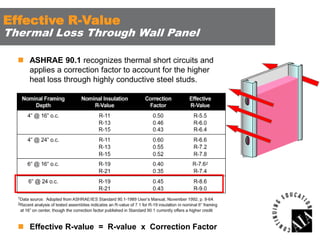

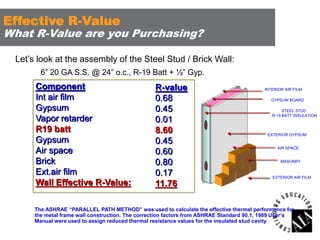

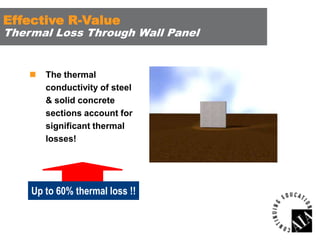

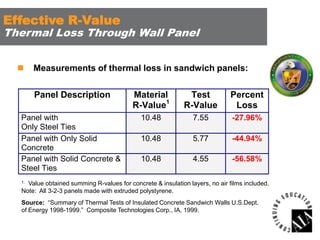

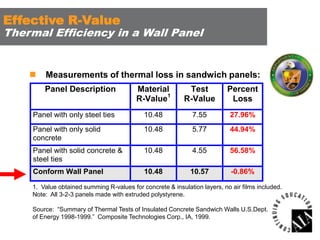

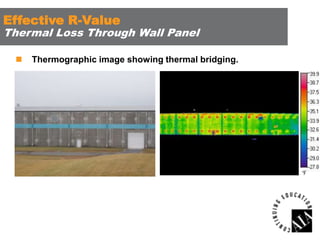

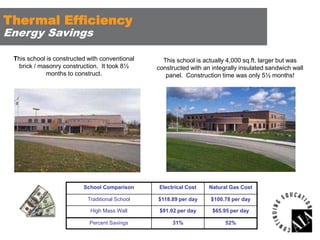

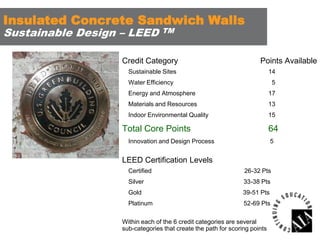

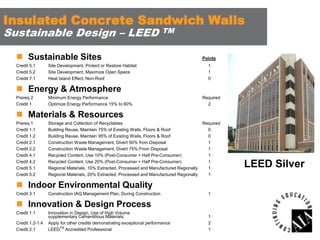

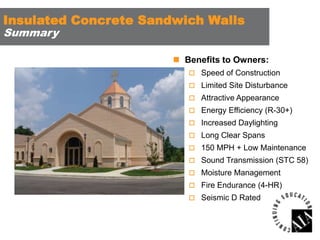

Andy Turner from Nuform Building Technologies presented on building envelopes and thermal mass walls. [1] Nuform was founded in 1992 and provides building systems and technologies. [2] The presentation covered the benefits of envelope construction including speed of construction, limited site disturbance, and energy efficiency. [3] It also discussed moisture management, wall physical performance characteristics like R-values and sustainability, and the various types of concrete wall panels and insulation options.