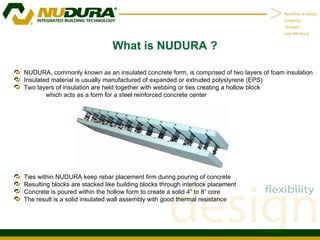

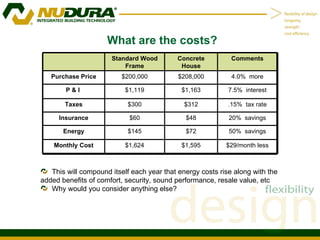

NUDURA is an insulated concrete form (ICF) building system made of two layers of foam insulation held together by ties that create hollow blocks. These blocks are stacked like building blocks and filled with concrete to create solid, insulated walls. NUDURA walls have superior structural, thermal, moisture, and acoustic performance compared to traditional wood-framed walls. They are also more resistant to fire, wind, flooding, and damage from elements like dry rot or termites. NUDURA construction combines framing, insulating, and wrapping a building into one process for faster, easier construction.