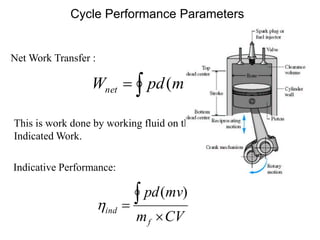

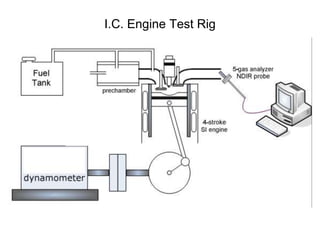

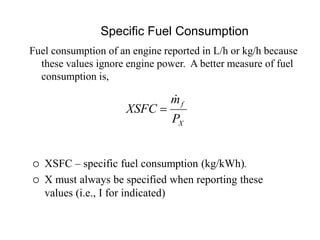

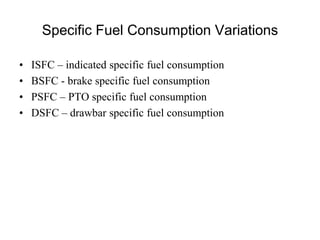

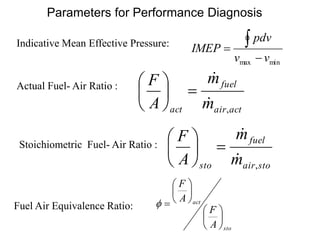

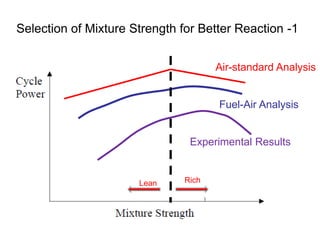

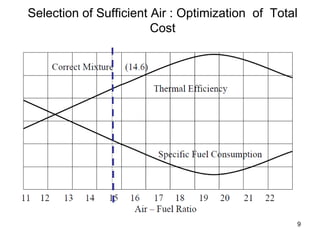

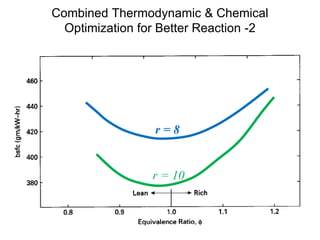

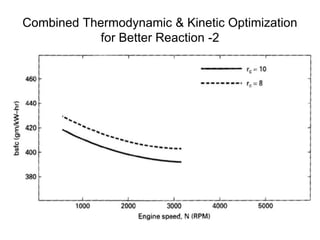

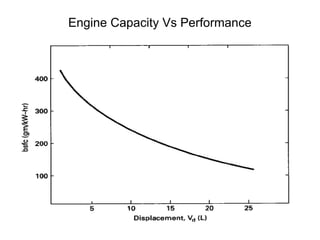

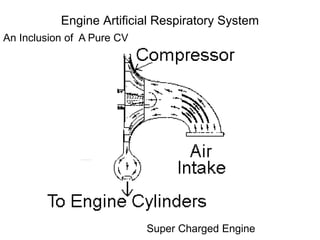

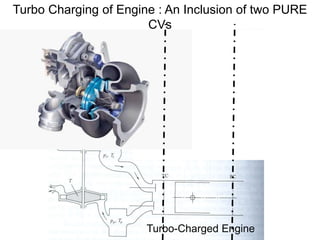

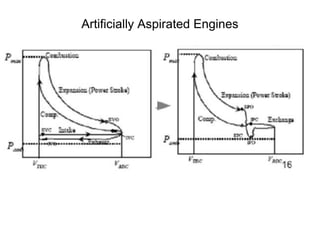

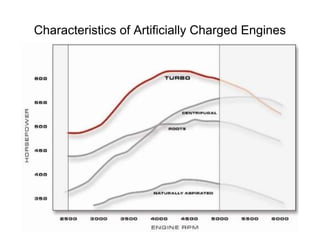

This document discusses methods for improving engine performance, including through artificially aspirated engines. It analyzes parameters like indicated work, specific fuel consumption, indicated mean effective pressure, and fuel-air ratios. The document suggests that engines are most efficient near peak load and that artificial breathing attachments can help overcome the necessary design compromise between engine size and efficiency. It proposes turbocharging as an effective artificial respiratory system for engines through the inclusion of two pure control volumes.