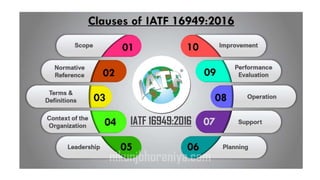

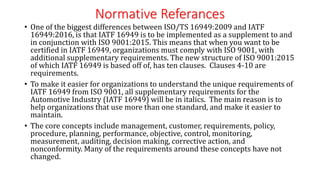

IATF 16949:2016 is a quality management standard for the automotive industry, based on ISO 9001:2015, and requires organizations to define the scope of their QMS clearly. It integrates supplementary automotive-specific requirements and emphasizes the importance of understanding organizational context and the needs of interested parties. The document outlines key requirements across various clauses such as leadership, planning, support, operation, and monitoring, with a focus on improving product safety and quality.