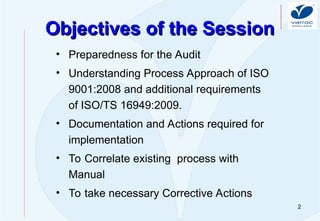

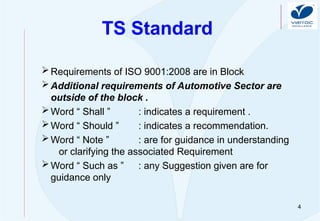

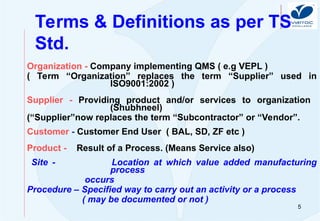

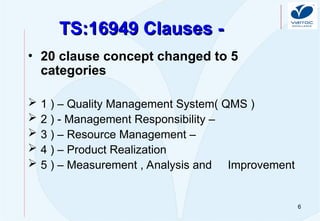

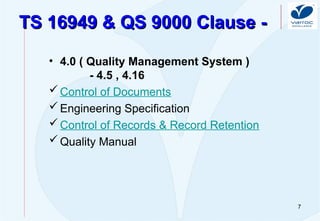

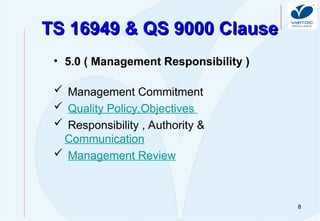

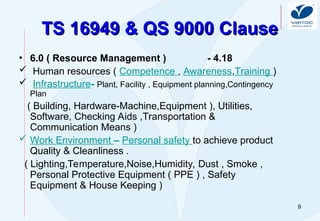

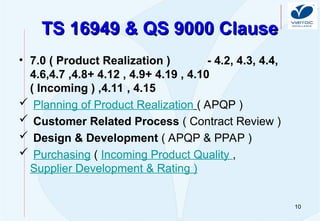

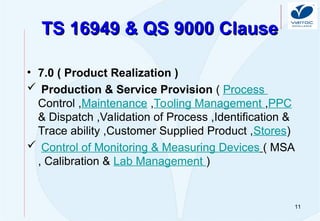

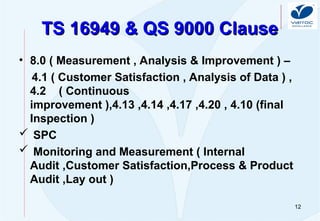

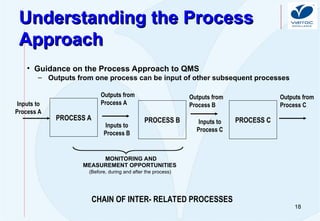

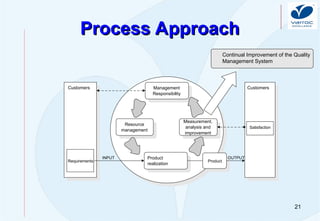

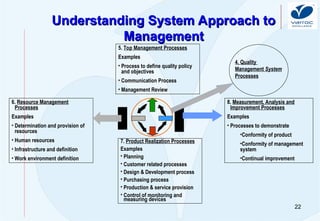

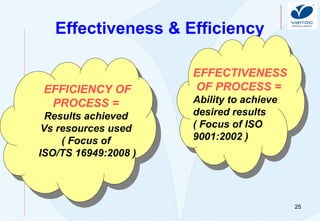

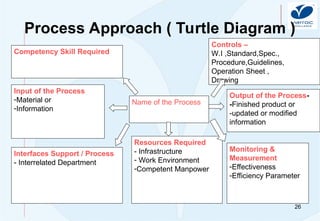

The document discusses the objectives and requirements of the TS 16949 awareness program conducted on January 4, 2012, aimed at preparing for an audit by emphasizing the importance of quality management systems in the automotive sector. It outlines various clauses of the TS 16949 standard which include quality management system, management responsibility, resource management, product realization, and measurement, analysis, and improvement. Additionally, it highlights documentation requirements, the process approach for QMS development, and the importance of effectively managing interrelated processes for continual improvement.