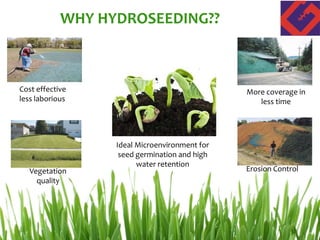

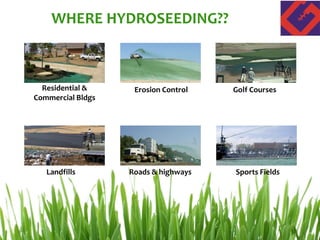

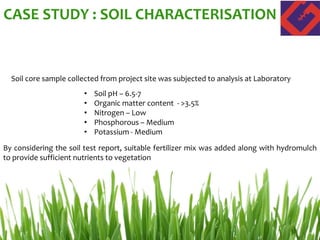

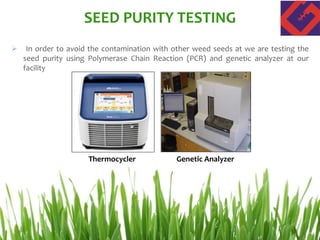

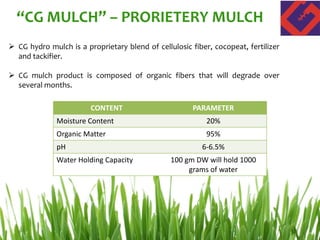

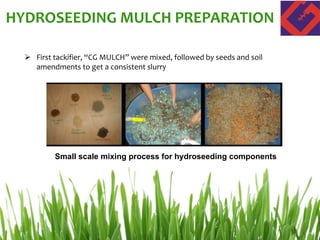

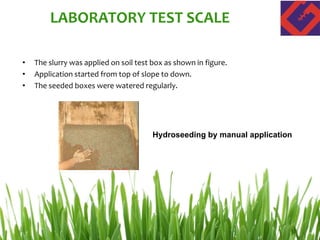

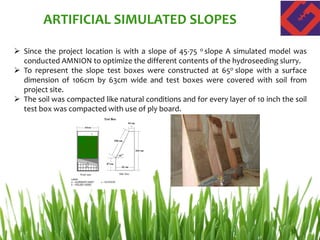

Coastland Geotechnics provides hydroseeding services for erosion control. Their team has extensive experience in geotechnical design and construction. Hydroseeding involves mixing seed, mulch, and amendments with water to form a slurry that is sprayed under pressure. This covers soil quickly and creates conditions for seed germination. Coastland demonstrated their hydroseeding methodology through laboratory tests and slope simulations. They optimized the slurry mix and established vegetation on steep slopes and through geotextiles to provide effective erosion control.