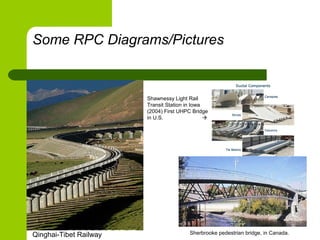

Reactive powder concrete (RPC) is an ultra-high performance concrete with compressive strengths over 120,000 psi due to its dense composition of fine particles, low water-cement ratio, silica fume, and steel fibers. It has excellent durability and flexibility compared to normal concrete. RPC is being used in bridges, seawalls, and other structures requiring light weight and high strength. However, its high cost is a drawback and research continues on reducing costs by using fly ash or slag cement.