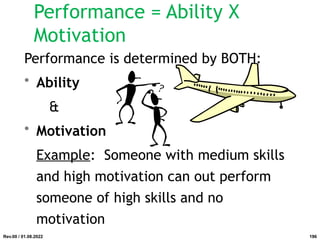

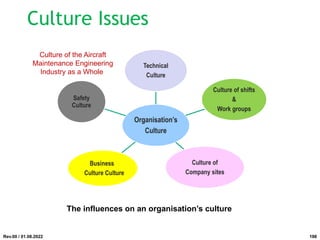

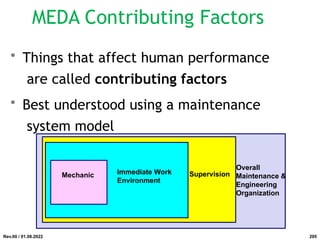

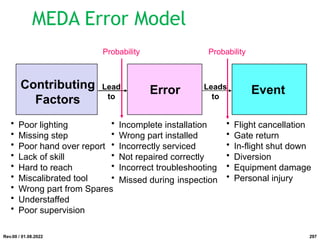

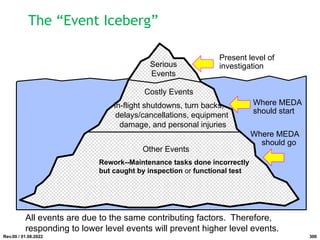

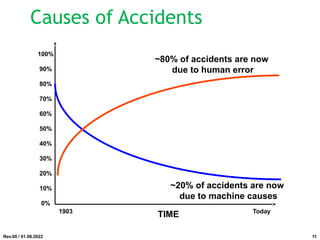

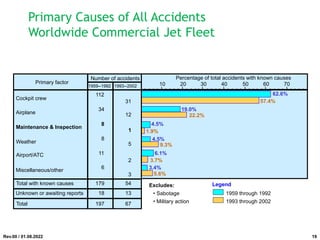

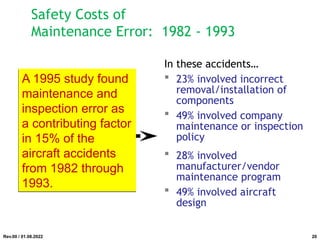

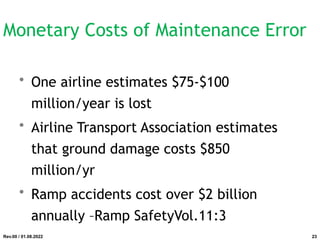

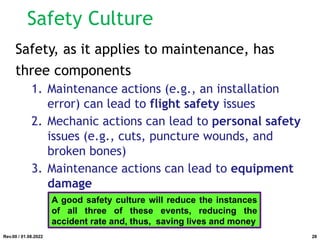

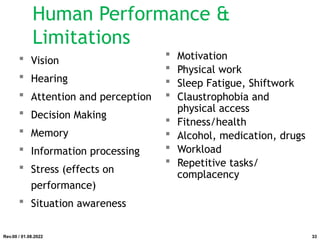

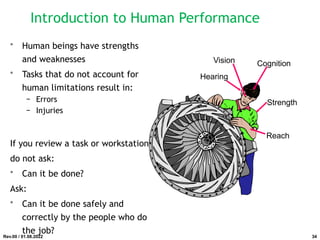

The document provides a comprehensive overview of human factors relevant to aircraft maintenance, highlighting the importance of understanding human performance, limitations, and organizational culture in enhancing safety. It discusses the significant role that human error plays in accidents and emphasizes the need for a safety culture to reduce risks associated with maintenance tasks. Additionally, it covers specific aspects like cognitive and physical factors, as well as communication and teamwork, to optimize maintenance practices in aviation.

![B737 double engine oil loss

AAIB report stated:

“Once the Controller and fitter had got to T2 and found that this supportive material

[Task Cards and AMM extracts] was not available in the work pack, they would have had

to return to Base Engineering or to have gone over to the Line Maintenance office to

get it. It would be, in some measure, understandable for them to have a reluctance to

recross the exposed apron area on a winter’s night to obtain a description of what they

were fairly confident they knew anyway. However, during the course of the night, both

of them had occasion to return to the Base Maintenance hangar a number of times

before the task had been completed. Either could, therefore, have referred to or even

drawn the task descriptive papers before the job was signed off. The question that

should be addressed, therefore, is whether there might be any factors other than

overconfidence in their memories, bad judgments or idleness which would dispose them

to pass up these opportunities to refresh their memories on the proper and complete

procedures.”

Rev.00 / 01.08.2022 69](https://image.slidesharecdn.com/bon-tek145-001humanfactorinitial-240823171711-0eea842b/85/BON-TEK145-001_HUMAN_FACTOR_INITIAL-pptx-69-320.jpg)

![This is one of the most critical aspects of communication within

aviation maintenance, since inadequate logging or recording of work

has been cited as a contributor to several incidents.

In the B737 double engine oil loss incident in February 1995, for instance,

one of the conclusions was:

“…the Line Engineer…had not made a written statement or annotation on

a work stage sheet to show where he had got to in the inspections”.

The reason for this was because he had intended completing the job

himself and, therefore, did not consider that detailed work logging was

necessary. However, this contributed towards the incident in that:

“the Night Base Maintenance Controller accepted the tasks on a verbal

handover [and] he did not fully appreciate what had been done and what

remained to be done”.

Rev.00 / 01.08.2022

Work Logging and Recording

159](https://image.slidesharecdn.com/bon-tek145-001humanfactorinitial-240823171711-0eea842b/85/BON-TEK145-001_HUMAN_FACTOR_INITIAL-pptx-159-320.jpg)